UNITED GRINDING's Vast, Advanced Technology to Stand Out at GrindTec 2014

Company to display several new innovations from WALTER, EWAG and STUDER in Hall 7-7050Ã- MIAMISBURG, Ohio – UNITED GRINDING, the largest single-source provider of complete and integrated grinding solutions, will showcase its latest grinding, eroding, laser and measuring innovations for general purpose and advanced tool and cutter production in Hall 7-7050 at GrindTec, taking place March 19...

Read More »

Drill Grinding Machine handles point and split point jobs.

With point geometry and sizing under NC, PS52 offers 3 parallel operations with load/unload simultaneous to point and split grinding. System accommodates multiple part-program storage and can produce drills from 1/16-Ã-½ in. to max overall length of 6 Ã-½ in. Production capabilities also extend to point included angles from 80Ã-

Read More »Punch and Die Grinder resurfaces turret press tooling.

Featuring 42 x 48 in. footprint, Model PDG has center-mounted rotary fixturing that holds punches and dies up to 6 in. in diameter with fixture enhancements available to sharpen dies up to 8 in. Punch fixturing allows sharpening of straight as well as shear angle punches with up to 10Ã-

Read More »

Angle Grinder features quick change wheel system.

Weighing just 6 lb, 6 in. W11-150 Quick compact class angle grinder suits cutting and grinding applications in metalworking and mechanical maintenance industries. Features included are 9.6 A motor, 1,100 W of power, 29.2 in.-lb of torque, and no-load speed of 9,000 rpm. Unit also comes with encapsulated on/off switch, carbon brush holders, double-lipped labyrinth sealed bearings, and...

Read More »

MITIGATING OPTICAL SUPPLY CHAIN RISKS

This white paper provides an overview into mitigating the optic supply chain, common issues and proposed solutions.

Read More »Cordless Cut-Off/Grinder features paddle switch design.

Built with 4-pole motor, 4Ã-½ in. M18 Model 2680-22 operates at speeds up to 9,000 rpm and includes L-shape intake vents to keep harmful debris from entering tool and damaging critical components. Grinder also features 3-position handle, tool-free adjustable guard, and Overload Protection to prevent damage in abusive situations. MilwaukeeÃ-® 18V XC High Capacity LITHIUM-ION technology...

Read More »Angle Grinder features 12.2 A motor.

Weighing just 6.3 lb, WE14-150 Quick 6 in. suits heavy duty cutting and grinding applications in metal working and mechanical maintenance industries. It offers 1,400 W of power, 31 in.-lb of torque and no-load speed of 9,000 rpm. It comes with wheel guard, inner flange, and flange kit for mounting both type 1 and type 27 wheels. Other features included are encapsulated on/off switch,...

Read More »

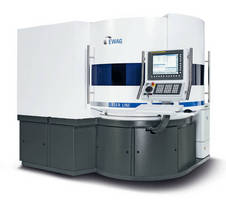

CNC Grinder grinds small cutting tools.

Designed for grinding cutting tools with diameters down to 0.5 mm, Model RX7SP includes linear scales for positioning accuracy of machine axes, V-block clamp, PLX pallet loader for unattended operation, and 3.5 kW HSK spindle that gives both face and taper contact on arbor for optimal wheel runout. With iBalance software, grinding wheels can be accurately balanced without taking them off machine.

Read More »New Cutter Grinding Steady Rest

Arobotech Systems Grinding AUTO RESTÃ-® is now available as a cutter grinder steady rest. The industry leader in precision and reliability applies an innovative wear pad design to provide the best workpiece support system for tool manufacturers. Our new on-part adjustment allows in-process corrections for unprecedented quality while the standard self-centering feature reduces changeover time.

Read More »

Grinding System processes technical ceramics.

Laboratory-sized Q-2 circulation grinding system features flame-proof electricals and is sealed for grinding under inert gas. Metal free with ceramic-lined grinding chamber, mill features zirconium oxide sleeved agitator arms and Halar coated premix/holding tank. Dual dosing/additive tanks enable adjustments to premix-holding tank, and device utilizes 2.2 gal media volume with 5-20 gal...

Read More »

Grinders automatically regrind punches and dies.

Featuring multiple user-specified grinding programs, MPG Grinders allow for material removal in increments as small as .0002 in. to provide precise sharpening while avoiding overgrinding. One version allows manual adjustment of grinding wheel relative to top of tool component, while other version features laser sensor to automatically detect wheel position relative to tool. Both have fully...

Read More »

Delivery Equipment That Really Delivers

Are you in need of safer, more efficient transportation equipment? Do you feel like your delivery equipment could really use an upgrade? Check out this video, and learn about Halo Ramp Company's patented safety platforms, and how they help you bypass your trickiest delivery challenges.

Read More »