ECTC is 1 Month Away! Visit Yincae Booth # 506 May 31st to June 3rd

ECTC is 1 MONTH AWAY! VISIT YINCAE BOOTH # 506 May 31st to June 3rd Albany, NY – ECTC is only 1 month away! The tradeshow will take place at The Cosmopolitan hotel in Las Vegas, NV from May 31st to June 3rd. YINCAE hopes that you will stop by our Booth 506 to learn more about YINCAE and the innovative products we have to offer. YINCAE offers a variety of exclusive Adhesives, Thermal Interface,...

Read More »Henkel Solder and Thermal Innovations Earn Industry Recognition

Henkel Adhesive Technologies’ Electronics business was the big winner at the NPI Awards presented at last month’s APEX event in Las Vegas.Ã- Scoring victories in the Solder Materials and Underfill/Thermal Interface Materials categories for its LoctiteÃ-® GC 3W and Gap PadÃ-® EMI 1.0 materials, respectively, Henkel continues its streak of award wins for innovative product...

Read More »

New Type of Paste with Enhanced Thermal Conductivity for Modules - TIM Allows Higher Power Density for Same Ageing Resistance

New Type of Paste with Enhanced Thermal Conductivity for Modules – TIM Allows Higher Power Density for Same Ageing Resistance Power electronics are experiencing a continuous rise in their power densities. As a consequence, thermal management for today's power semiconductors must be integrated as early as their design phase. Only then can reliable cooling be safeguarded over the long term. A...

Read More »

Laird Technologies to Attend Strategies in Light 2013

Company to Showcase Thermal Interface Materials St. Louis, Missouri, USA - Laird Technologies, Inc., a global leader in the design and supply of customized performance-critical components and systems for advanced electronics and wireless products, today announced it will attend Strategies in Light 2013. The event will take place at the Santa Clara Convention Center in Santa Clara, California,...

Read More »

A Comparative Guide to Sweeteners in the Food and Beverage Industry

To learn more about the benefits of agave over other sweeteners, and how Come Alive Organics can help source your needs, download now.

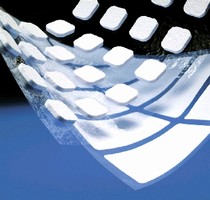

Read More »Phase Change Thermal Interface Material supports screen printing.

Screen-printable and stencilable, Tpcm(TM) 580SP Series exhibits 4.0 W/mK thermal conductivity. Pad contains solvent that assists in processing, which allows wetting of surface. After drying, the solvent is moistureless to the touch, and therefore eliminates mess associated with thermal grease. Once solvent is removed, material begins to soften and flow at temperatures around 45Ã-

Read More »

China's Leedarson Blazes Trail in LED Lighting with Stylish, White Heat Sinks Using LNP* Konduit* Compound from SABIC Innovative Plastics

PITTSFIELD, Mass. - SABIC Innovative Plastics today announced that Leedarson Lighting - a leading end-to-end private label lighting manufacturer and provider of energy saving lighting solutions - has selected LNP* Konduit* thermally conductive compound in a new white formulation to manufacture heat sinks for two of its light-emitting diode (LED) retrofit bulbs. Headquartered in Xiamen, China,...

Read More »

Henkel to Show Latest Materials Innovations at APEX 2010

Irvine, California - Customers visiting Henkel at the upcoming APEX 2010 event in Las Vegas will quickly discover that partnering with the materials leader is no gamble. A continued emphasis on product innovation and R&D investment - even throughout the recent downturn - has placed the company firmly at the top among electronics materials suppliers, with materials solutions and global resources...

Read More »

Spinnaker Coating Announces New Polypropylene Film

Troy, OH -Spinnaker Coating now offers 4 mil TC Matte White Polypropylene. The extra thickness of this film, compared to lower caliper material, allows it to have excellent success in thermal transfer machines. The stiffness is ideal for print-and-apply and print-and-present label applications, and it performs as well or better than other similar films touting the same dispensing benefits. In...

Read More »

Thermal Interface Material features silicone-free design.

Suited for silicone sensitive applications, GORE(TM) POLARCHIPÃ-® SF3000 fills air gaps between heat generating devices on PCBs and heat sinks, heat spreaders, and metal chassis that are used to dissipate heat. Fluoropolymer composite consists of expanded polytetrafluoroethylene matrix filled with boron nitride particles. Absence of silicone eliminates problems of silicone outgassing and...

Read More »

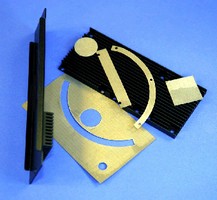

Thermal Interface Material comes in 5 and 10 mil thickness.

Designed to attach heat sinks to hot PCB components, KoolBond(TM) consists of fine woven, nickel-coated copper fiber matrix with pressure-sensitive adhesive on outside. Woven copper closely conforms to irregular mounting surfaces to optimize thermal transfer, while double-sided PSA eliminates screws, clips, or other hardware. Thermal impedance is 0.42Ã-

Read More »

Trotec Laser Offers Customizable Industrial Laser Marking Solutions for Any Application

Trotec's laser marking solutions provide your company with configurable workstations and intuitive, customizable software. Check out our video to learn more.

Read More »