FlexArm Donates Tapping System to Local Vocational Training Program

Wapakoneta OH – Apollo Career Center is a well-known and established training center just outside Lima, Ohio. They offer vocational programs committed to training area youth and adults for tomorrow's careers. Apollo is proud of its training program and the workforce development it provides, according to its website at www.apollocareercenterhs.com. Among the graduates of the Apollo High School...

Read More »

Automating 0.38mm Diameter Smart Tapping for a Watch Manufacture

SMAC has successfully automated a tapping process for a major watch manufacturer in Switzerland. The process has been carefully done by hand under microscope for many years. Tap diameter is 0.38mm. Part has a diameter of 3mm and is 0.25mm thick. The R&D manager at the facility says that he has been in this business for 20 years and there is no other tapping device existing in the market for this...

Read More »GE Fanuc Automation Expands Capabilities of CNC Learning Control Function Greatly Improving Productivity for High Volume Machines

Next Generation of Learning Control Provides The Ability To Achieve High Speed and High Precision For Any Machining Application CHARLOTTESVILLE, VA, NOVEMBER 29, 2006 GE Fanuc Automation, a unit of GE Industrial, has announced that it has expanded the capabilities of its learning control function for parts cutting and rigid tapping providing the ability to apply the high speed and high precision...

Read More »

Tapping Machine taps 4000 holes per hour.

RapidTap can tap 18 holes with 3 different pitches simultaneously in aluminum alloy die-casting. Semi-automatic design minimizes operator fatigue and ensures every hole is tapped, eliminating human error. RapidTap is powered by 3-phase inverter, providing necessary torque. Inverter control allows rpm to be increased or decreased to suit smaller or larger taps. Machine can be re-tooled and...

Read More »

Key Considerations for Medical PCB Assembly

This white paper provides an overview of key considerations for medical PCB assembly.

Read More »

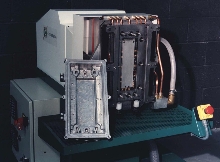

Machining Center provides drilling, tapping, and milling.

Mill Drill Center offers 12 x 10 x 12 in. work cube and 15,000 rpm 40-taper spindle, powered by 15 hp vector drive system. Ballscrews and high-torque servo motors on all axes provide rapids to 2,400 ipm and accelerations to 0.8 G. Automatic tool changer stores up to 20 tools and changes them in 1.5 seconds. Dual fixture stations allow operators to load and unload parts on one fixture while...

Read More »

Tapping Center offers speed of 16,000 rpm.

Brother TC-32A CNC, with rotating, pallet Quick Table, allows for machining of work piece on one side of table during setup of another work piece on opposite side. When machining operation is completed, Quick Table rotates 180 deg. Tool magazine holds up to 27 tools, and automatic tool changer performs 2.2 second chip-to-chip tool changes. TC-32A includes internal magnetic type motor,...

Read More »

560 and 572 Series IP67 Waterproof Inline Plug and Socket Connectors with Shock and Vibration Resistance

EDAC's new line of IP67 waterproof plug and socket connectors represent the cutting edge of waterproof connection technology. Part of the 560 and 572 series of connectors, they utilize innovative design concepts to deliver a level of performance and value that is unmatched in the industry. See our video to learn more.

Read More »