Plasma System expands from 4 to 8 cells to increase capacity.

Along withÃ- 65 x 69 x 97 in. chamber and 4–8 cell (8–16 panel) capacity, ModVIA™ provides technology to treat PCBs for desmear and etchback as well as provide surface activation. Integrated system accommodates diverse PCB panel technologies in various shapes and sizes, including rigid, flexible, through-hole, and blind via, and works withÃ- range of process gases: such as Ar, O2,...

Read More »

3DT's Popular MultiDyne Corona Treating System Now with Improved Treating Heads for Better Performance and Savings

Germantown, WI, USA.Ã- – 3DT LLC of Germantown, Wisconsin has updated its MultiDyne corona treating heads from a molded head to an assembled one. This change assures a sturdier platform for consistent surface treatment. Additionally, should a component fail over time, it can easily and inexpensively be replaced; a cost-saving benefit to customers. MultiDyne improves adhesion on 3-D parts...

Read More »Chemical Etching Methods of Floor Treatment

There are methods of making mineral surface floors slip resistant that make use of mild acids to make an invisible tread pattern in the surface of the stone.Ã- These acid based products make a microscopic tread pattern on the surface of the stone that creates slip resistance without changing the visible appearance of the surface.Ã- Porcelain bathtubs can be made slip resistant as well...

Read More »FlexVIA Plasma System from Nordson MARCH Wins New Product Introduction Award for Surface Treatment of Flexible PCB Materials

Concord, California, USA - Nordson MARCH, a global leader in plasma processing technology, received the New Product Introduction (NPI) Award for its FlexVIA™ Plasma System, a completely self-contained vacuum plasma system designed for maximum efficiency and cost-effective etch, desmear and surface activation treatment of flexible printed circuit boards (PCBs). The award, presented by Printed...

Read More »

Industrywide Applications for Deep Drawn Metal Stamping

Deep-drawn metal stamping applies a significant punching force to radically draw metal sheets into a die cavity. Finished components produced by this process tend to have a depth that exceeds their diameter, which is why manufacturers refer to it as "deep-drawn" metal stamping.

Read More »Effective Chemical-Free No-Touch Cleaning

Chemical-free cleaning is the latest innovation in Green cleaning, and Kaivac's No-Touch(TM) Cleaning technology is perfect for many chemical-free cleaning situations. With No-Touch Cleaning, pressurized water agitates and loosens soils on surfaces. Immediate vacuuming removes moisture along with the soil. Studies report that when compared to mops and buckets, it is far more effective at leaving...

Read More »Plasma Treatment System optimizes PCB yield.

Designed for manufacturing high density interconnect, flex, and rigid panels, ProVIA(TM) requires minimal floor space. Vacuum system, plasma chamber, control electronics, and 40 kHz power supply are housed in single enclosure. Full front and rear access allows for service to all interior components, and no side access is required. Pump is positioned on rollers to facilitate removal.

Read More »

Wide Array of Breakthrough Surface Treatment Technologies on Display at ICE USA

Menomonee Falls, WI - Enercon Industries Corporation is pleased to announce its ICE exhibition booth 1035 will include new and breakthrough surface treating technology for a wide array of applications. New Atmospheric Plasma Solutions Plasma4(TM) and Plasma Synergy(TM) Enercon's Atmospheric Plasma Technology Director Rory Wolf will present Synergistic Plasma Technique for Achieving Remarkable...

Read More »

Hi-Tech Concrete Coatings, Inc. Applies Floor Coating to Maintenance Hangar for the Federal Aviation Administration

Hi-Tech Concrete Coatings, Inc. completed a 38,000 square foot maintenance hangar, circa 1940, for the Federal Aviation Administration, Ronald Reagan National Airport, Washington DC. Surface preparation included removing multiple layers of coatings that had been applied over many years. Scarfiers and carbide-tipped scraping machines were used to remove the existing coatings. Damaged joints and...

Read More »

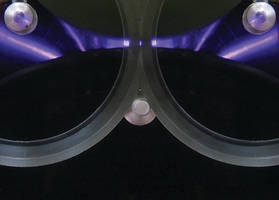

Surface Treatment System generates blown-ion discharge.

Suited for conductive and non-conductive material, Dyne-A-Mite(TM) IT Elite etches, cleans, activates, sterilizes, and functionalizes surface. Concentrated blown-ion discharge causes micro-etching or scrubbing effect, removing organic and inorganic contaminants and facilitating application and adhesion of coatings, adhesives, inks, labels, and markings of all types. Quality control is...

Read More »Plasma Treatment System processes flexible PCB materials.

Addressing need for processing of flex materials such as polyimide, LCP, and others, Model FP64 System is used for surface activation of coverlay material in flex panels to promote adhesion and prevent delamination. It is capable of running up to sixteen 18 x 24 in. panels per run for throughput performance of 64 panels/hr. All major components required for system operation such as vacuum pump...

Read More »

Error Proofing by Design

Sturtevant Richmont's torque tools help customers cut rework and warranty costs while increasing throughput.

Read More »