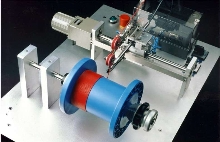

Independent Machine Company Computerized Respooler With Liner Inserter

IMC introduces its latest innovation in computerized spooling equipment. The offline single position respooler traverse winds a composite string from a previously wound spool. Adjustable constant unwind tension is controlled by an electronic brake through ultrasonic diameter measurement feedback. The driven capstan is the main speed reference of the machine and provides tension isolation between...

Read More »

Pneumatic Spooling Unit handles 2 control lines.

Suited for offshore and onshore applications, Dual Pneumatic Spooling Unit enables users to run 2 different fluids at different pressures simultaneously with complete control and safety. Pneumatic mechanism uses air which is then exhausted into atmosphere for environmentally friendly operation. System accommodates control lines of various sizes, as well as spools of various weights.

Read More »

Spool Gun targets aluminum welding applications.

Designed for Power MIG(TM) 255C and Power MIG 350MP wire feeder/welder systems, Magnum-® 250LX is capable of feeding .030 to 3/64 in. dia aluminum wire or .025-.035 in. dia steel wire on up to 4 in. dia spools at speeds up to 800 ipm. It features 3-½ turn wire speed control at gun for fine adjustment of wire speed, eliminating need to walk back to power source to change speed. Rated 280 A/60%...

Read More »

Optical Flange Detector enhances spooling accuracy.

Optical Flange Sensing System enhances winding accuracy when used with Uhing traverse winding drives. Two versions are available: one relies on reflective properties of spool flanges, and one uses light curtain concept that does not require reflected light. Both systems employ opto-sensors to detect spool flanges and signal pneumatic or electronic switch to flip spring-actuated reversal lever on...

Read More »

Epoxy Crusher Backing Solutions for Construction Aggregate & Ore Mining Applications

This white paper provides a guide to epoxy crusher backing solutions for construction aggregates and ore mining applications.

Read More »

Multi-Spindle Winder offer max line speed of 500 fpm.

Modular Model MS 104 runs either independently or series-coupled with other modules to control entire take-up line. Each module contains 20 moving parts, and all components are accessible from front or rear of unit. With standard tension of 8-32 oz, winder handles packages weighing up to 80 lb and measuring up to 18 in. diameter and 12 in. wide. Adjustable traverse assembly and lay on roller...

Read More »

Spool Gun suits aluminum welding applications.

Spoolmatic-® 15A, with 15 ft cable assembly, offers nozzle assembly that balances gun evenly in operator's hand. Capable of wire feed speeds from 70-875 ipm, unit pushes wires with .023-1/16 in. dia and holds one 4 in. spool. Additional offerings include adjustable barrel assembly that allows operator to vary contact tip-to-nozzle position, built-in gas valve, and ability to adjust wire speed at...

Read More »

Spool Changer holds 6 spools.

Automatic Spool-Changer automatically changes spools without stopping wire drawing or annealing production process, allowing up to 8 hours of continuous operation. It fits on existing or new wire equipment to reduce labor costs and increase productivity.

Read More »

ISO-Certified Precision Machining and Contract Manufacturing Services from DFF

DFF is an industry leading contract manufacturer specializing in medium to high production precision machined components and electromechanical assemblies. Our 100 CNC machining centers and design-assist capabilities ensure our customers' needs are always met. Check out our video to learn more.

Read More »