Wire Splices help improve electrical performance.

Made from nickel-plated steel, tinned brass, and brass, U-Band and Autoband Splices make in-line connections and butt splices with solid/stranded wires using automatic applicators. Dimples, serrations, and ribs increase holding force between wire and wire ear, and products improve electrical performance by mechanically disrupting oxides during crimping. They come in sizes for combined wire and...

Read More »

Aerial Wedge Spice suits slack span and tension applications.

QIKSLEEVE(TM) features all-aluminum, open design that allows visual inspection, does not trap water, and eliminates corrosion issues due to dissimilar metals. Anti-reverse clip assists in initial installation of connector, while visual indicator verifies installation. Field re-adjustment capability helps eliminate potential of scrapping incorrectly applied splices. QIKSLEEVE meets ANSI C119.4...

Read More »

Splice Kits target telecom and electrical markets.

HYREDUCER and HYSPLICE Kits provide in-line reduction or splice of 2 conductors. They are pre-packaged with connector and length of heavy-duty black or clear heat shrink tubing that has passed Telcordia GR-347-CORE Abrasion and Cut Test. Inspection holes in connectors ensure conductor has been fully inserted. All connectors are UL listed.

Read More »

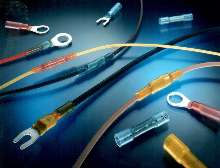

Heat-Shrinkable Splices and Terminals accept 22-10 AWG wire.

Raychem(TM) DuraSeal(TM) heat-shrinkable splices and terminals insulate and protect electrical connections from mechanical abuse, wire pull-out, and abrasion. Impact-resistant products also serve as wire strain relief and resist water, salt spray, and debris. Configurations include butt splices; fork, ring, push-on, and bullet terminals; tabs; and pins. Dual-wall, adhesive-lined nylon insulation...

Read More »

Advantages of Nylon Washers and Other Non-Metallic Materials

Check out this white paper to learn about the types of non-metallic washers.

Read More »

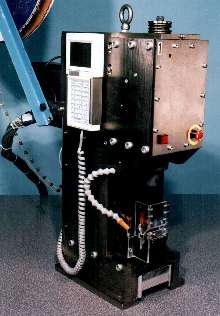

Splicing System facilitates pigtail splicing of magnet wire.

Magnet Wire Splicing System allows manufacturers of motors and magnetic coils to pigtail splice up to 8 magnet wires and 2 lead wires with Circular Mill Area (CMA) up to 38,000. Servomotor-driven, 5 ton press incorporates pneumatic-feed applicator and programmable control cabinet. Wire-entry guides allow accurate positioning of magnet and lead wires into splice before crimping. Programmable...

Read More »

Snips evenly distribute leverage.

Model 925CS-ERGO ergonomic snip has one blade with ergonomically shaped cushioned palm rest and one blade with traditional ring bow. Features include one serrated blade, stripping notches for 19 and 23 ga. wire, scraper and file on top of blades, and cushion grip. Precision-ground, cutlery grade carbon steel blades are double-plated with chrome over nickel.

Read More »

Ultrasonic Wire Welder is microprocessor controlled.

SpliceRite(TM), with 1500 and 2500 W power capacities, produces solid-state metallurgical bonds in wire harnesses and other types of wire bundles. Splicing system welds without melting wires or producing arcs, sparks, or fumes. Capable of welding multiple strands in one pulse, it can store and perform up to 250 weld protocols, allowing for selection of welding modes by time, energy, and distance....

Read More »

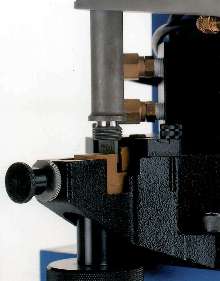

In-Register Butt Splicer feeds narrow web label applicators.

Model SSBSC-IR performs butt splices at zero speed with single-sided tape always applied to same side of web. Splices may be made between labels, while single roller dancer maintains process speed during splicing operation. Product is available in various web widths and roll diameters.

Read More »

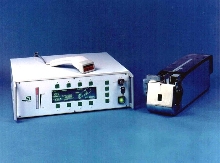

Ultrasonic Splicer has modular design.

Raptor, with menu-driven ST 3000 II controller, connects wires ranging from 22 to 4 ga, using ultrasonic welder to make splice sizes from 0.7 to 40 mmÃ-². It is encased in heavy metal shell to dampen vibrations, eliminate bends and deflections, and maximize efficiency of vibration energy. LCD screen displays settings and 3-D diagram to key components to help operators set, store, and retrieve...

Read More »

Splicing/Ironing Machines have in- or off-line designs.

Opti-Splice(TM) 1000 & 2000 machines utilize ultrasonic energy to splice (1000 series) then iron (2000 series) material to form continuous runs of fabric that accommodates any width. Ironing creates smooth, unobtrusive joint that increases seam strength. Portable and self-contained, equipment can be used on multiple lines for end-to-end web splicing. Both Opti-Splice(TM) 1000 and Opti-Splice(TM)...

Read More »

560 and 572 Series IP67 Waterproof Inline Plug and Socket Connectors with Shock and Vibration Resistance

EDAC's new line of IP67 waterproof plug and socket connectors represent the cutting edge of waterproof connection technology. Part of the 560 and 572 series of connectors, they utilize innovative design concepts to deliver a level of performance and value that is unmatched in the industry. See our video to learn more.

Read More »