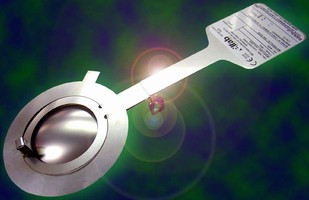

Rupture Disc Holders feature pre-torqueable design.

Made of 316 stainless steel, TQ+ Disc Holders allow rupture discs to be installed and torqued to recommended static load levels with proper clamping of rupture disc within assembly. Units come in standard sizes from 1-6 in. with serrated gasket faces per ANSI B16.5, and DiscLoc(TM) locator, which helps prevent inverted disc installation. Holders can be installed in multiple international flange...

Read More »Elfab Increases ASME VIII Product Approvals

Safe-Gard earns UD stamp for use in North America Cincinnati, OH (June 21, 2007) - Pressure-management specialist Elfab has expanded its range of ASME VIII-approved bursting discs with the addition of the Safe-Gard forward acting rupture disc. With a proven track record protecting liquid, gas and vapor services in Europe, Safe-Gard is the latest bursting disc from Elfab to successfully undergo...

Read More »

Bursting Disk is designed for low-pressure applications.

Intended for liquid, gas, or vapor applications from 2 psig, Opti-Gard(TM) SoLo reverse-acting bursting disk features 95% operating-to-burst pressure ratio and 3% performance tolerance. Unit comes pre-fitted with integral Flo-Tel(TM) non-invasive, magnetic burst-detection system, which is fail-safe and operates only when disk has ruptured. Standard construction is of corrosion-resistant...

Read More »

Oseco to Feature PROLP Disk at ISA Expo

Broken Arrow, Oklahoma (September 29, 2006)-The high quality, ultra-low pressure PROLP rupture disk will be Oklahoma Safety Equipment Co., Inc.'s (Oseco) featured product at the Instrumentation, Systems and Automation Society (ISA) Expo October 17-19 in Houston. The PROLP rupture disk operates in very low pressure vessels, where equipment operating costs are key considerations. It has a fully...

Read More »

How Manufacturing Automation Can Reduce Workplace Injuries and Improve Morale

To learn more about how automation can solve your workplace issues, download the full white paper.

Read More »

Rupture Disk Holders suit forward- and reverse-acting discs.

Universal slimline rupture disk holders for Opti-Gard(TM) and Safe-Gard rupture disks feature standard face-to-face dimensions to facilitate replacement of existing holders. Holders incorporate multi-flanged design that interfaces with both Flo-Tel(TM) magnetic burst-sensing system and excess flow valves.

Read More »

Pressure Relief Assembly prevents leakage problems.

Designed to prevent environmental contamination in severe process conditions, Double-Disc Opti-Gard comprises primary and secondary rupture discs, as well as pressure gauge or switch to monitor space between discs. In event of chemical attack causing pinholing of primary disc, back-up prevents pollution of environment, while intermediate pressure sensor warns maintenance teams. Disc is...

Read More »Rupture Disk/Sensor provides sanitary pressure relief.

Offered in sizes from 1-4 in., Model S-PRO-S combines bursting disk and sensor into single assembly with range of burst pressures from 16-150 psig. When disk bursts, sensor's circuit is broken, triggering activation of alarm. Placement of sensor and disk scoring on vent side present smooth surface to process, minimizing product build up. Non-fragmenting design prevents contamination from rupture...

Read More »

Rupture Disks feature vacuum support design.

For processes that operate under vacuum conditions, rupture disks with vacuum support ensure that disk does not collapse under differential back-pressure and operates correctly. One-piece vacuum support eliminates potential failure sites and has smooth design that reduces accumulation. Rupture disks are suited for agricultural/bulk powder, aerospace, chemical, gas, petroleum, pharmaceutical, and...

Read More »Rupture Disk suits demanding pressure applications.

PRO+ Rupture Disk features 95% operating ratio to guard against fatigue and premature disk rupture for both gas and liquid services. It operates without using cutting teeth. One-piece design and smooth surface prevent product buildup. With burst pressures from 8-750 psig, disk is compatible with wide range of applications and performs consistently in high- and low-pressure environments.

Read More »

Rupture Panels handle extreme pressures.

Series MVRB Metal Vent Reverse Buckling rupture panels can avert catastrophic explosions caused by overpressures in dust collectors, conveyor systems, and dryers. Smooth surface prevents product buildup and contamination, while non-fragmenting design increases process safety in event of panel rupture. Round panels range from 12-36 in. dia and come in SS, nickel, inconel, or monel. They feature...

Read More »

DoorKing Releases Advanced Long Range Card Reader System with Frequency Hopping Technology

The DoorKing DKS AVI system is at the cutting edge of automotive security technology and represents a leap forward in engineering innovation. When it comes to long-range passive card readers, we lead the industry and set the standard for quality and performance. To find out why the DoorKing DKS AVI system is taking the automotive security industry by storm, see our video.

Read More »