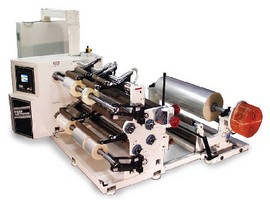

Duplex Slitter/Rewinder Ideal for Metalized Films and Foils

Model SR7000 slitter/rewind is designed for thin gauge films at low tensions. (Neenah, Wis.) - The Model SR7000 Duplex Slitter/Rewinder from REM is designed for thin gauge films, foils and packaging materials. Capable of running 84-inch wide webs at 1500 FPM, the SR7000 model can handle 48-inch diameter unwind rolls while producing 24-inch diameter slit rolls at rewind. Pull rolls are placed...

Read More »Independent Machine Company Computerized Respooler With Liner Inserter

IMC introduces its latest innovation in computerized spooling equipment. The offline single position respooler traverse winds a composite string from a previously wound spool. Adjustable constant unwind tension is controlled by an electronic brake through ultrasonic diameter measurement feedback. The driven capstan is the main speed reference of the machine and provides tension isolation between...

Read More »Elsner Recently Shipped its' First Model GWR-760 High Speed Fully Automatic Wallcoverings Rewinder

Elsner recently shipped its' first Model GWR-760 high speed fully automatic Wallcoverings Rewinder with the Model OW-30-C Shrink Film Roll Overwrapper to a European customer. The New GWR-760 incorporates features of the companies existing high speed Rewinders used for lighter weight papers and films with new, heavy duty rotary cut-off knife and rolling head systems to better handle the heavy...

Read More »

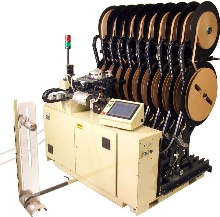

Multi-Reel Rewinder suits high-speed stamping processes.

To maximize unattended winding capacity, automatic Wyndamster 3210 incorporates 10-reel operation with side-by-side reel design. It coils any product strip up to 2.5 in. wide and accommodates reels up to 30 in. in dia. Operating at speeds up to 650 ipm, machine can function in overwind or underwind mode; complete conversion from one direction to other takes less than 1 min. Features include...

Read More »

Peristaltic Pump Vs. i-FILL® Technology

Intellitech's advanced i-FILL® pumps are used by companies working in some of the world's most demanding sectors, delivering innovative, highly accurate and repeatable results, ensuring ultimate reliability and ease of use for all of our clients.

Read More »

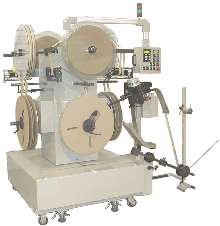

Oscillating Unwinders/Rewinders accept small coil spools.

Traverse wound oscillating unwinders and rewinders accommodate small hole spools by locking them in place via conical seats on twin spindles that engage each side. Coil spools or carriers move sideways in synch with speed so pickoff or deposit point remains horizontally fixed. This results in scan wound or unwound coil without induced camber. Spindles open up to release coil, and units feature...

Read More »

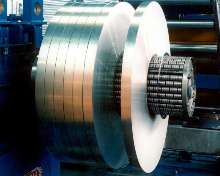

Core Slip Rewinding System provides constant coil tension.

Slip Tech system consists of core winding surface made entirely of bearings, which reduce friction between core surface and winding drum. This eliminates excess tension in individual rewound coils during build up, resulting in ability to maintain consistent coil tension because each strip is independently tensioned from core to finished coil OD. Product can also eliminate need for looping pits in...

Read More »

Multi-Reel Rewinder is suited for small floor spaces.

Wyndmaster 348 consists of fully automatic, 8-reel take-up that can be used with any product strip up to 3 in. wide and any reel diameter up to 30 in. It uses 4-position horizontal indexer with 2 reels at each position and receives product at speeds to 600 ipm. Features include paper interleaf operation, tangential feeder, and automatic sample strips with programmable length. Changeover is timed...

Read More »

Rewinder is surface-driven.

Designed to user specifications, Surface Driven Rewinder offers low/high tension flexibility of shaft-driven rewinder, but decreases shaft-related workplace injuries and speeds roll changes. Compact, portable unit includes steel construction and low-tension brake control for gentle handling of material. Options include end-of-roll sensor, 4-station razor-slitting capability, edge trim removal...

Read More »Dual Spindle Label Rewinder is suited for desktop slitting.

TWIN-CAT-2 Rewinder utilizes 2 powered rewind spindles with Quick-Chuck(TM) Core Chucks to handle multiple rewind cores for slitting or to rewind finished label and waste matrix rolls for die-cut label matrix stripping operations. Product offers heavy-duty, steel construction and allows users to remove waste matrix from die-cut labels as they rewind from printer.

Read More »

Hand-Crank Shafts are suitable for narrow-web setups.

Hand Crank Mechanical Shafts, available in diameters of 70 mm and larger, are designed specifically for narrow-web applications. Products are suited for light loads and provide moderate torque.

Read More »

Ensure Your Medical Device Meets Regulatory Standards with Triad's Custom Magnetics

Triad Magnetics' custom components for medical devices are designed and manufactured with the strictest regulatory standards in mind. Our capabilities include rapid design, prototyping, and testing of inductors, transformers, and power supplies for medical equipment. Check out our video to learn more.

Read More »