Mold Release suits in-mold painted polyurethane applications.

Providing smooth defect-free parts that replicate fine surface details of mold, Release Coating 7887 offers dry, tack-free surface feel and resistance to scuff and mar. Water-based product maximizes number of parts that can be made before cleaning molds by minimizing build up through blend of wax and silicone. Desired gloss quality can be specified by customer.

Read More »

New Water Based Semi-Permanent Mold Release Agent

February 20, 2009 McLube has developed a new water based semi-permanent mold release for organic rubber compounds and parts called MAC-973. The product will reduce mold release usage by allowing for the maximum number of parts to be released per application of the mold release. Thus, molders will improve their molding efficiency resulting in a lower operating cost. Proven benefits include reduced...

Read More »

Release Coating targets flexible foam applications.

Optimizing adhesion of cloth or foam topping materials, Release Coating 7232 is effective in producing seating components for off-road vehicles, including SUVs and trucks, as well as in manufacturing of armrests and head restraints. Minimal buildup extends time molds remain on production line producing parts. Coating is packaged in 5 gal pails, 55 gal drums, and 345 gal totes.

Read More »

Mold Release Agent is designed for cultured marble surfaces.

Available in 1 gal containers and 5 gal pails, Mold Release Coating 7512 is formulated specifically for cultured marble vanities and sinks. Use results in quality surface with smooth feel, reflective shine or luster, and natural appearing color variations. Developed under guidance of ISO 9001 Quality Management System to ensure consistency in product quality, solution exhibits facilitated release...

Read More »

Hydrogen and Check Valves

Hydrogen powers various sectors, offering cleaner energy solutions. This white paper describes the different types of hydrogen as well as the crucial role of reliable check valves in its production, storage, and distribution.

Read More »

Mold Release Agent suits automotive interior components.

Specifically formulated for low gloss in-mold-painted applications, water-based Release Coating 7307 optimizes scuff and mar surface characteristics. Molded surfaces have uniform, low gloss appearance over entire surface area along with dry surface feel. Available in 5 gal pails and 55 gal drums, agent is effective at spray outputs up to 180 g/min.

Read More »Coatings aid in mold release processes.

Mold Release Coatings 6944, 7123, and 7153 provide clean mold release for composite friction materials such as automobile and truck brake composite products. Coatings are non-silicone, water based, dilutable concentrates available in 55 gal drums and 275 gal totes.

Read More »

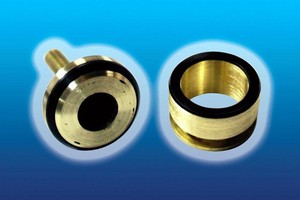

Release Agent improves rubber bonding in molded-metal inserts.

Model EZR324 semi permanent mold release agent provides semi-permanent molded release performance while promoting bonding to molded rubber-metal inserts. Water based agent is suited for EPDM and natural rubber, and is available in 5 gal pails, 55 gal drums, and 275 gal totes.

Read More »Coating lets molders choose necessary level of release.

Flex-Z family lets molders incrementally adjust level of release needed for specific parts and processes. HAP-free Coatings, from 1.0-6.0, provide level of release performance desired, enabling molders to switch between levels of product for different molds or apply simultaneous levels of product to one mold. Formula eliminates streaking across full range of application techniques. It suits open...

Read More »Mold Release Agent works with polyurethane substrates.

Water-based FrekoteÃ-® AqualineÃ-® PUR-100 is suited for releasing rigid, high-density polyurethane foam and cast polyurethane parts. It delivers multiple releases from one application and can also release some low-density polyurethane foams. Non-toxic, non-flammable coating is freeze/thaw stable and formulated with very low levels of VOCs. Mold release agent does not settle and requires...

Read More »Release Agent is suited for flange sealing.

FrekoteÃ-® EFR, formulated to seal porous flange surfaces on composite molds, provides multiple releases per application. Semi-permanent, polymeric release agent is also suited for abrasive processes such as polymer concrete molding. High slip coating is capable of releasing highly filled and abrasive compounds and may be applied at temperatures ranging from 55 to 110Ã-

Read More »

Von Ruden's Driven Tools Are Built to Last

Von Ruden's driven tools are designed to each specific machine in order to maximize performance. All of our tools are performance tested and made in the USA per ISO 9001:2015 standards. Check out our video to learn more.

Read More »