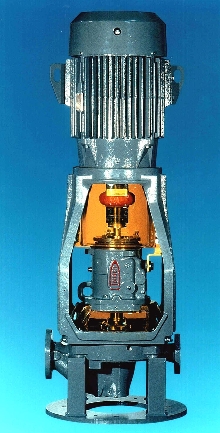

Chemical Process Pump exceeds ASME (ANSI) B73.2M criteria.

Mark III In-Line pump has SealSentry(TM) seal chambers with flow modifiers that redirect flow from circumferential to axial. Self-flushing, self-venting, and self-draining seal purges heat, solids, and vapors, thus extending seal and pump life. Pump has micrometer impeller adjustment, reverse-vane impeller, and precision motor and pump shaft alignment system for alignment within 0.002 in. ANSI...

Read More »

Pump transports dewatered sludge cake.

Open-hopper BTH Pump transports materials up to 3 million cp and municipal wastewater sludge with over 50% solids. Feed auger operates separately from pump rotor shaft, allowing auger to operate concentrically and to be driven at speed that is independent from pump speed. Design completely separates fluid shearing action from pumping rate. It also reduces bridging inside pump because auger...

Read More »

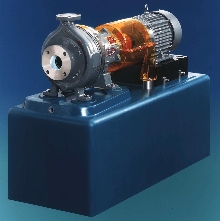

Polymer Baseplate forms foundation for pumps.

Polyshield Baseplate and Foundation is made from polymer mix using epoxy resins. Single unit replaces traditional baseplate and formed concrete foundation for pump-driver sets. It provides flat mounting surfaces, 1-piece motor mounting block, chemical resistance to aggressive liquids, high vibration dampening characteristics, and less maintenance. Baseplate and foundation can be installed in 1-½...

Read More »

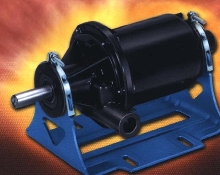

Positive Displacement Pump handles wide range of fluids.

Model 301 Series Progressing Cavity Pump handles applications from clean, clear liquids to abrasive fluids. It pumps at flow rates to 13 gpm at discharge pressures up to 25 psi. Pump has phenolic housing and rotor, making it suited for corrosive chemicals. Reverse covered seal between rotor and shaft eliminates metal exposure to fluids. Resilient cushion and cradle mounting on self-priming pump...

Read More »

Peristaltic Pump Vs. i-FILL® Technology

Intellitech's advanced i-FILL® pumps are used by companies working in some of the world's most demanding sectors, delivering innovative, highly accurate and repeatable results, ensuring ultimate reliability and ease of use for all of our clients.

Read More »

Magnetic Drive Pumps have no seals, don't leak.

Self-priming pumps are available in polypropylene/PVDF or high temperature PVDF materials, making them suitable for acids, alkalies, caustics, bleaches, sea water, solvents, and other harsh environments. There is no metal contact with liquid being pumped. Power is transmitted by magnetic field from magnet attached to motor through solid body of pump to magnet attached to impeller. Pumps have no...

Read More »

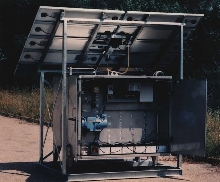

Injection System provides uninterrupted well operation.

Model EKO Solar-Powered Injection System for oil and gas wells is fully self-contained and features sealless metering pump that can inject corrosion inhibitors at up to 72 gal per day against 3,700 psi. Pump has 2 PTFE diaphragms that isolate process fluid, providing double containment with zero-leakage, run-dry tolerance, and overload protection. It requires less than 160 W of DC power, which is...

Read More »

Vacuum Pump works at variable pumping speeds.

Inverter equipped DYM series high speed dry vacuum pump provides pumping speeds from 330 to 1,200 m3/hr. It combines company's DR-C series dry pump and PRC-A series mechanical booster pump. Pumps are close coupled inside enclosed frame for CVD and etch applications, and unit is coated with TUFRAM(TM) for resistance to corrosive chemicals and wear. It has control system, RS232C interface, and...

Read More »

Double-Diaphragm Pumps are abrasion-resistant.

Husky(TM) self-priming, air-operated pumps are designed for abrasive materials such as ceramics and slurries. They are offered in 1, 1 1/2, 2, and 3 in. models. Air valve with closed-center design eliminates sticking commonly experienced with spool valves. One inch through 2 inch pumps use common center diaphragm. Two inch model matches inlet to outlet dimensions of WildenÃ-® and AroÃ-®...

Read More »Recovery Systems offer custom configurations.

Condensate Commander Pumps feature 125, 200, or 250 psig ASME cast steel tanks for operating pressures up to 250 psi at 400Ã-

Read More »

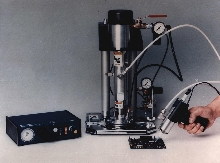

Pump transfers fluids from can to dispensing valve.

Model FK001 Autoscan System transfers viscous material directly to valve, which can be mounted on automatic dispensing robot or supported in handgrip gun. It accommodates 1 quart and 1 gallon sizes. Follower plate wipes material from sides of can, preventing mess. When used in combination with Model 790HPNM suck-back valve, system provides production aid for higher viscosity materials up to...

Read More »

Triad WAU Wall Plug-In AC Power Supply May Be First To Meet Level VI Energy Efficiency Standard

Triad Magnetics, an industry leader and one of the most trusted names in transformer design and manufacturing, is proud to announce the release of the Triad WAU Wall Plug-In AC Power Supply. Engineered to provide robust performance and high reliability, it is setting the standard for 120V/60Hz power supplies. See our video to learn all about it.

Read More »