Wing Pulleys are available in CEMA-rated style.

Chevron wing pulleys are rated for CEMA construction applications, which are often light-duty, portable conveyors that make infrequent starts and stops. Units have V-shape construction to deflect material and prevent it from lodging, maximizing pulley life and minimizing belt damage. They are available with diameters from 10-20 in. and face widths from 20-63 in., and in Mine Duty and Super Duty...

Read More »

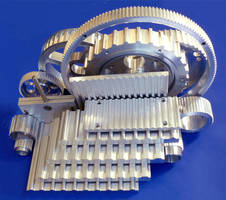

BRECOflex Co., L.L.C. - Metal Parts for Belt Drives

March 25, 2009 Timing Belt Pulleys - Flat Belt Pulleys - Idlers - Tensioners - Clamps - Tensioning Clamps Metal Parts made to order in less than 1 week !!! BRECOflex Co., L.L.C., the market leader in polyurethane timing belts, is proud to introduce a break through in regard to the lead time for Metal Parts for the timing belt industry. Made to order Timing Pulleys, flat Pulleys and Idlers, as...

Read More »

Nordex Belt and Chain Drives

Nordex manufactures Timing Belt Pulleys to industry standards as well as custom Pulleys. The improvements in timing belt technology allow close manufacturing tolerances of the profiles which helps create the smooth entry into and out of the mating pulley. This both reduces wear and provides greatly enhanced positioning accuracy. Engineers are finding uses for the Nordex belt system in a variety...

Read More »

High-Torque Timing Pulleys

Misumi (www.misumiusa.com) has added sizes to its line of metric/inch aluminum, carbon and stainless steel high-torque timing pulleys for 2006. 14-72 teeth, easy positioning, no backlash, longer teeth designed to improve transmission and reduce noise. Misumi timing pulleys are available for use with 14 different belt styles and and can be manufactured with a variety of center holes such as round,...

Read More »

Setting Yourself Up for Sales Success

This ebook provides tips on creating and implementing best practice front-end sales processes.

Read More »

Timing Belt Pulleys feature integral hub fastening design.

Made of clear anodized aluminum alloy, 3mm Pitch HTDÃ-® Series A 6D23 (inch) and Series A 6D23M (metric) are available in 10-44 grooves with bore sizes from .125-.250 in. and 3-6 mm. Outer diameters range from .346-1.624 in. and 8.8-41.4 mm. FairlocÃ-® integral hub fastening design eliminates need for separate hub clamp devices and offers benefits of frequent position adjustment, while...

Read More »Nylon Pulleys dissipate static electric build up.

Specifically designed and manufactured for static-sensitive applications, Pulleys and Accessories are made of nylon with PAN carbon fiber additives, which stop electrical charge build-up, dissipate charges from high-speed motion, provide grounding path, and prevent discharge to and from human contact. Built up of static electricity can cause end product loss and downtime in manufacturing and...

Read More »

Timing Belt Pulleys feature integral hub fastening system.

Designed for Ã-¼ in. belts, .080 pitch MXL Series A6D16 is made of clear iridite aluminum alloy and available with 12-72 grooves in double- or no-flange types. Bore sizes range from .125-.250 in., and ODs range from .286-1.813 in. FairlocÃ-® integral hub fastening design eliminates need for separate hub clamp devices, and offers benefits of frequent position adjustment, while adding...

Read More »

Timing Belt Pulleys feature integral hub locking system.

Comprised of 34 HTDÃ-® pulleys made of clear anodized aluminum alloy, A 6D23-(inch) and A 6D23M (metric) Series double flange type timing belt pulleys have 3 mm pitch and are designed for .236 in. belts. FairlocÃ-® integral hub fastening design adds positive metal-to-metal fastening strength along entire hub surface. Products, available from stock in 10-44 grooves, come in bore sizes from...

Read More »Small Pitch Timing Belt Pulleys synchronize shafts.

Designed for Ã-¼ and 3/8 in. wide synchronous toothed belts with 1/5 in. pitch, Series A 6A 3, A 6C 3, A 6J 3, A 6M 3, and A 6Z 3 are suited for machine tools, mowers, and business machines. Units are available in double-flanged, single-flanged, and flangeless styles, as well as hubbed and hubless versions. With bores ranging from .1875-.500 in., pulleys are made of aluminum alloy, steel,...

Read More »

Timing Belt Pulleys feature integral hub locking system.

Available with 15-120 grooves, A 6D51- (Inch) and A 6D51M (Metric) Series include 44, 2 mm pitch GT-®2 pulleys made of clear anodized aluminum alloy. Fairloc-® integral hub fastening design eliminates need for separate hub clamp devices, enables frequent position adjustment, and adds positive metal-to-metal fastening strength along entire hub surface. Designed for 6 mm belts, pulleys are...

Read More »

Precision Machining Solutions with Over 25 Years of Experience

Quality, customer service, and unbeatable value are the hallmarks of Hogge Precision. Since 1989 we have built a reputation as the go-to precision machining source, servicing many demanding industries. For CNC machining and screw machining, there are few manufacturers that can match our capabilities and expertise. See our video to learn more.

Read More »