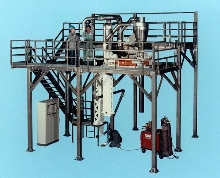

Modular Processing Systems offer turnkey solution.

Modular Processing Systems, for material processing, are factory-engineered and pre-assembled, minimizing on-site labor for erection, custom fitting, and unforseen factors. Systems include structure and individual equipment as required including Multi-AspiratorÃ-®, cyclones, fans, filters, airlocks, spouting, and automation. Systems are suitable for industries such as grain and milling,...

Read More »

Quartz Growth Systems suit high and medium pressure processes.

Hydrothermal Quartz Growth Systems constantly control temperature and pressure within forged pressure vessel. Average cycle time is 24 to 36 days, depending on size and quality of crystals required. Equipment is suitable to make quartz components used in a wide range of applications including oscillators, frequency filters, telecommunication systems, microprocessors, color televisions, and time...

Read More »Wafer Transport Robot replaces processed wafer in 4 seconds.

Axys(TM) FastSwap atmospheric robot uses dual-yaw wrist architecture enabling wrist/end effectors to rotate 360Ã-

Read More »Front-End System is optimized for 300 mm wafer applications.

Plus(TM) Portal XT incorporates IsoPort(TM) 300 mm load port, which includes configurable front-opening unified pod latch-key mechanism, multiple info pad and mechanical pins, and multiple E-84 ports. It also includes FastSwap(TM) wafer-handling robot, which uses dual-yaw wrist architcture to conduct rapid wafer exchanges in and out of OEM's tool. Smart-Plus(TM) control system interface ensures...

Read More »

6 Reasons to Consider Hydroforming over Traditional Metal Stamping

To learn more about the functions of the hydroforming process, the key differences from other processes, and why it is preferable over other stamping options, download this eBook now.

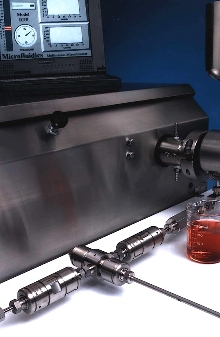

Read More »Overlay Measurement System processes 150 wafers per hour.

NRM-3000 provides automatic measurement of overlay and NSR focus marks. Illumination system is bright and optically matched to imaging system. It employs fiber optic delivery system to quartz-halogen lamps. System utilizes actively damped stage and EGA alignment control technology to assure correct measurements. Software offers recipe management functions. Waferless recipe creation offers...

Read More »

Metal Chip Briquetter turns scrap into profits.

Compact PaceSetter(TM) Series II is available in 5 capacity ratings up to 6,400 lb per hr of aluminum. It transforms metal chips, fines, turnings, bushy metal scrap, and sludge from aluminum, cast iron, steel, brass, or copper into dense, dry briquette pucks. System also recovers cutting oils and coolants for re-use, saving money and reducing environmental liabilities. Briquetter system includes...

Read More »

Conveyor And Briquetter recover separated coolent.

ConSep 2000Ã-® II combination, single-platform chip conveyor/coolant separator removes chips and contaminates to 50 micron level. Features include self-cleaning backwash filter system, and cleaner for particulate removal to 10-15 nominal micron level. FastPac(TM) Briquetter processes 110 to 6,614 lbs of metal chips per hour (depending on model) and transforms material into dense, dry...

Read More »Load Port handles 300 mm semiconductor wafers.

Automated IsoPort(TM) has front-opening-unified-pod (FOUP) tool carrier interface, servo-controlled motion, latchkey, and carrier sensing. Tool throughput is 8 sec, from carrier arrival to first-wafer access. Contamination control conforms to ISO Class 1 particle level, and eliminates triboelectric charge buildup on carrier door. Optional gas purge ports provide an inert ambient environment for...

Read More »

Mixer Reactor produces nanoparticles.

NMR high-intensity Multiple Stream Mixer Reactor produces uniform nanoparticles such as planarization media, superconductors, abrasive silica, recording media, photographic production and pharmaceutical products. Multiple streams of reactants, pressurized up to 40,000 psi, are fed in stoichiometric ratios into mixing chamber. Reactor uses computer controls to adjust multiple stream flow by...

Read More »

Press Production Unit offers interchangeable furnaces.

Hot Isostatic Press Production Unit (HIP) applies uniform pressure at elevated temperatures to all surfaces, making it suitable for castings, ceramics, plastics, automotive, and aerospace industries. Inside diameters range from 50 to 1,500 mm. Units contain pressures from vacuum to 3,000 bar and temperatures up to 4,000 deg F. They offer cascade control and fast cooling or uniform fast cooling to...

Read More »

Basalt America Announces Stronger, Lighter, and Corrosion-Free FRP's (Fiber Reinforced Polymers)

Fiber Reinforced Polymers (FRP), represents a truly groundbreaking advancement in structural reinforcement. Lightweight, strong, and green, they are changing the way the construction industry thinks about rebar. Unlike steel, FRPs don't rust and are far stronger than standard rebar. To learn why Fiber Reinforced Polymers are poised to change the way the world builds, see our video.

Read More »