Microperforation Systems provide adjustable hole sizes.

VentPerf needling tools and systems are suited for micro-perforation and cutting of film, paper, foil, laminates, and non-wovens. Various designs provide ventilation, moisture release, or product expansion for agricultural and consumer good packaging as well as technical materials. Up to 600 holes/sq in. are attainable at speeds to 600 fpm. Products can be integrated into in-line processes, or...

Read More »

Press Feed System suits heavy-duty applications.

Space-Saver(TM) Electronic Servo Press Feed System incorporates piloting design into integral pull-thru straightener. Suited for lines that may be used to straighten or feed materials of 0.035 in. thickness or greater, Toggle Link Motion Straightener configuration ensures all upper rolls of mechanism are raised to equal height. This releases tension between upper and lower rollers of straightener...

Read More »

Rubber Presses are offered in various types.

Maxi-Jet(TM) Rubber Injection Systems and Maxim(TM) Hydraulic Compression and Vacuum Presses are suited for molding rubber, silicone, and composites. Maxi-Jet(TM) injection presses are available in sizes up to 10,000 cc, while Maxim(TM) presses are available with clamping forces up to 1,000 ton and platens up to 42 in. Custom designs are also available.

Read More »

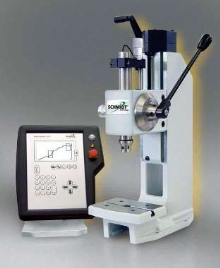

Manual Press features electronic stroke and process control.

Intended for intricate press-fit assemblies, rack-and- pinion ManualPress 307/3000 System offers press forces from 25-900 lb, 100% process verification, force and distance monitoring, and statistical process control. It includes touch-screen display and menu-driven software. Bench-top unit features .0004 in. resolution micrometer stroke adjustment and overall adjustable stroke from 0-1.9685 in....

Read More »

Choosing the Best Industrial Facial PPE Supplier: 5 Key Factors

Paulson is an industry leader in PPE production, most notably face and eye protection. Learn more now about what factors are most important to consider when choosing a PPE supplier.

Read More »

Fastener Installation Presses include automation package.

PEMSERTERÃ-® Series 2000Ã-® Automatic Presses, equipped with Automation Signals Package, include expanded outputs, signal collector, and all necessary software and hardware modifications to start process of robotic or automation integration. With throat depth of 24 in., presses offer cycle rates from 2,750-3,600 strokes/hr and ram force of 400-16,000 lb. They include PLC and touch screen...

Read More »

Tablet Press features fully automated operation.

Designed for use in trial and development stage of new product development, 102i is capable of running single- , bi-, or triple-layer tablets as well as core tablets. It offers direct scale-up capabilities with 1, 3, or 4 punches as well as interchangeable die tables with 6-12 stations, combined B and D table, or full die table. Included R&D Galenic software package tests compacting abilities of...

Read More »

Pneumatic Toggle Presses offer real-time force monitoring.

Toggle-AireÃ-® presses are available with process monitoring controls that validate proper operation and provide interrupts, alarms, and documentation required for ISO compliance. Displays show ram position to Ã-

Read More »

Rubber Molding Presses offer ergonomic working height.

Ergo Series is equipped with FIFO screw/ram injector that delivers uniformly plasticized and metered-size shot. Constant L/D ratio guarantees homogenous preparation of compound. Microprocessor control allows process parameters to be set digitally on control panel. Presses include linear positioning system for clamping and injection side, 5 temperature control zones, separate control panel for...

Read More »Tablet Press utilizes automated washing system.

Courtoy MODUL(TM) Tablet Press contains all powder within Exchangeable Compression Module (ECM) for product changeover in as little as 30 min. Wash Off Line cleans ECM after it is removed from tablet press, while MODUL remains in operation, producing another product during cleaning cycle. Self-contained ECM is removed from press onto trolley, and trolley is rolled to wash skid, where 3 spray...

Read More »

Tooling punches mounting holes in 19 in. enclosures.

Designed for fabrication of mounting holes in electronic enclosures, 19 in. Racking Cluster(TM) tooling consists of punch, stripper, and die assembly. Punch is solid cluster of three 0.375 x 0.375 in. punch points on 0.625 in. centers. Middle punch has protrusion on 2 sides to produce positioning and centering slot that facilitates installation of racks into 19 in. wide enclosure boxes. Product...

Read More »

Industry Leading OEM with over 65 Years of Experience

Blonder Tongue Laboratories provides ISO 9001:2015 certified electronic contract manufacturing services at our on-site lab. We specialize in video distribution, fiber optics, and communications but have a variety of services available to bring your products to market. See our video to learn more.

Read More »