Bright Tin Acid Process suits rack and barrel electroplating.

Based on sulfuric acid electrolyte, Technibrite HT 1000 has low current density bright range, even when plating bath temperature and tin concentration parameters are higher than normal. Process can run without chiller, and will produce bright deposit at low current densities at process temperatures as high as 35Ã-

Read More »

Lead Tinning System complies with military standards.

Suited for low- to mid-volume in-house re-tinning of electronic components and leads, Anthem Lead Tinning System(TM) is fully ANSI, MIL, IEC, and GEIA compliant. System features 2 dynamic solder pots, pre-heat station, and flux station, as well as precision ball screw drives for quiet motion control. Programming control includes solder temperature; dynamic solder flow; emersion depth...

Read More »

Novellus' Suppression-Enhanced Fill(TM) Technology Provides Defect-Free 32nm Copper Interconnects

Unique Hardware and Process Chemistry Extend Cu Manufacturing Capability SAN JOSE, Calif., April 9 / -- Since the advent of copper damascene processing, achieving void-free fill of high aspect ratio interconnect features has been a key challenge for device manufacturers. Shrinking dimensions at each successive technology node have increased the complexity of the copper seed and electroplating...

Read More »

Automation System produces cable assemblies.

Built from modular components, TransferModule 6000 includes cable transport system, transfer shuttles, transfer chain, cable loading/unloading stations, control system, and PC-based user interface. Stations can perform stripping, tinning, sealing, shield flaring, and micro-flame soldering, as well as ultrasonic and resistance welding, connector housing insertion, and electrical testing. Typical...

Read More »Adhesive Tapes for Energy & Utility Applications

Read about the various types of tapes used in energy and utility applications.

Read More »Rohm and Haas Electronic Materials Develops Electrolytic Hard Gold Plating Process that Reduces Gold Consumption

Tokyo, Japan, October 24, 2006 - Rohm and Haas Electronic Materials announced the development of RONOVEL(TM) CS100, a new electrolytic hard gold plating solution that is capable of minimizing gold deposition onto unwanted areas during gold plating of components, such as connectors. Today gold plating is extensively used in electronic equipment and electronic components due to its excellent...

Read More »Copper Electrofill System handles 45 and 32 nm nodes.

Copper electroplating system, SABRE Extreme(TM), utilizes Viaform Extreme electrofill chemistry to provide filling capability on narrow, high-aspect ratio features. Along with sealed contact design with 1 mm physical edge exclusion, product features edge bevel removal process with recipe-driven edge exclusion and Extreme-generation plating cell that enables recipe-driven edge profile control. It...

Read More »Semitool's New Raider-® Platform Used by Casio to Increase Lead-Free Capacity for 300mm Wafer-Level Packaging

Semitool Delivers Follow-on Raider for 300mm Lead-Free Electroplating KALISPELL, Mont., Dec. 5 -- Semitool, Inc. (NASDAQ:SMTL), a leading manufacturer of advanced single-wafer deposition and surface preparation process equipment for the semiconductor and wafer-level packaging industry, today announced the delivery of a follow-on order for Semitool's electroplating Raider tool by Japan-based Casio...

Read More »

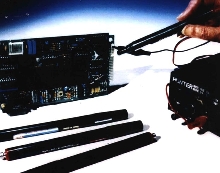

Metallizer System suits PCB repair and re-work applications.

Micro-Metallizer system utilizes disposable marker-type pens based on environmentally friendly plating compounds. System offers bench-top plating convenience, and completely eliminates preparing and handling solutions. Pens can be safely used anywhere. Pens are available in gold, copper, tin, zinc, nickel, black nickel, silver, chrome-color, rhodium, and palladium.

Read More »

Chemical Monitoring System employs CVS technique.

Quali-line QLC-6000 provides on-line chemical monitoring for copper electrodeposition process. Automatic system measures organic additives and inorganic components. Cyclic voltammetric stripping (CVS) technique offers logic based features and analysis development. QLC-6000's MicrosoftÃ-® WindowsÃ-® based platform supports GUI and touch screen monitors.

Read More »

TPA Motion Introduces New Curved Linear Rail Guides: the CR40 Series

For the ultimate in precision open and closed loop guided motion systems, TPA Motion is the leader in curved rail, liner guides. We specialize in engineering excellence, with products that exhibit an elevated level of precision, delivering robust performance, even under the most challenging conditions. See our video to learn more.

Read More »