CO2 Lasers range from 1-6 kW.

Designed to withstand harsh industrial environments, CO2 Lasers weigh about 150 lb each, and can be mounted directly above cutting surface. They enable unlimited travel area on XY cutting table since they do not require optical delivery system. Optical quality of beam is close to diffraction limit, while overall efficiency can reach 16%.

Read More »

ESAB Combination Waterjet/Plasma Cutting Machine Combines Speed and Accuracy

Florence, SC - ESAB Cutting Systems will demonstrate the Hydrocut LR multi-process waterjet cutting system at IMTS, Booth #B6157. This CNC shape-cutting machine uses ESAB's patented waterjet/plasma combination to produce cut parts using the speed of plasma and the accuracy of waterjet. The waterjet process can also be combined with many other cutting or marking process tools, including oxyfuel...

Read More »

Miller To Showcase New Plasma Cutter, TIG Welder, Helmet Designs and More at 2006 Fabtech International/AWS Welding Show

APPLETON, Wis., 2006 Miller Electric (booth #23040) will showcase several new products, enhancements to existing products and a new Roadshow semi trailer-- a traveling welding and cutting exhibition, complete with classroom--at the 2006 Fabtech International/AWS Welding Show in Atlanta. New products on display will include the SycrowaveÃ-® 200 AC/DC TIG/Stick welder, the SpectrumÃ-® 1251...

Read More »Plasma Cutting Systems utilize 200 A cutting current.

Equipped with XT(TM)-301 precision torch technology, Auto-Cut 200 and Auto-Cut 200 O2 are designed for cutting materials of 1 in. or less. While Auto-Cut 200 is optimized for air plasma cutting of mild steel, Auto-Cut 200 O2 is equipped with gas control box that gives it added efficiency for cutting with oxygen plasma. Both are suitable for stainless steel and aluminum when used in conjunction...

Read More »

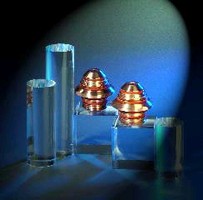

Plasma Nozzle helps optimize cut quality.

By eliminating small secondary gas ports, HyperthermÃ-® HT4400Ã-® Nozzle avoids spatter build-up. To further decrease spatter, specialized plating can be used when cutting thick materials. Designs are available for most high current applications.

Read More »Angle Cutter is designed to cut split face block.

Powered by 15 A, 3,500 rpm motor, model 4114 has 14 in. blade diameter and 5 in. cutting capacity. Position of tool body, adjustable from 0Ã-º to 80Ã-º, operates independently of cutting depth. Tool base can be removed for cutting closer to walls, while guide wheels on tool guard ensure smooth travel over surface material. In addition to vacuum attachment port, cutter features Super Joint...

Read More »Plasma Torch Kits increase cut speeds.

Designed for HyDefinition HD4070 metal cutting systems, HyPerformance torch-and-lead upgrade kits come with 6, 10, or 15 ft torch lead. Each contains 200 A machine torch, HyPerformance torch lead set, and upgrade software, plus upgrade field service bulletin and ID and safety labels. HyPerformance technology enables virtually dross-free, precision cuts consistently throughout full life of torch...

Read More »Air Plasma Cutter and Gouging System severs 1-¾ in. steel.

Weighing 97 lb, SpectrumÃ-® 1251 has 100 A output and has rated cutting capacity of 1.25 in. On thinner material, such as Ã-¾, and 5/8, and Ã-¼ in. steel, cutting rates rise to 25, 40, and 140 ipm, respectively. Unit also cuts stainless, aluminum, copper, and any metal that conducts electricity. In addition to Auto-Line(TM) power management technology, unit features Auto-Refire(TM)...

Read More »Laser Cutting System offers cutting area of 6 x 13 ft.

Based on 5,200 W resonator, Byspeed 4020 features Adaptive Radius Control technology, which provides automatic optimization of beam diameter to best process various sheet metal thicknesses and types. DHM drive technology delivers acceleration rates up to 3 G's along X and Y axis. Fully enclosed work zone maintains positive work environment, ensuring minimal noise and dust emissions, while...

Read More »Laser Cutting System offers 2-stage pulse piercing.

Bystar and Byspeed 5,200 and 4,000 W laser cutting systems utilize 2-stage controlled pulse piercing method that pierces through initial surface in stage 1 then switches to second stage where intensity of pulse is greatly intensified. Monitoring device determines when pierce-through has been achieved, and cutting motion is then initiated. Result is reduced heat input from smaller entry and...

Read More »

Triad's Next-Gen Power Supplies Offer Increased Reliability and Reduced Noise Performance

Triad Magnetics, an established leader in power supply design and manufacturing, is proud to announce their next generation WAU AC and WDU DC Series of power supplies. These linear wall plug-ins offer minimum noise performance without sacrificing reliability or life. See our video to learn more.

Read More »