Wisconsin Oven Ships One Electrically Heated Four Zone Conveyor Oven to Oil & Gas Industry

Wisconsin Oven Corporation announced the shipment of one (1) Electrically Heated Four Zone Conveyor Oven to a manufacturer in the oil and gas industry. The electrically heated conveyor oven has sufficient capability to heat 25 parts per hour with a heating time of 48 minutes and a cooling time of 12 minutes. Each chamber in this four-zone conveyor oven has a maximum temperature rating of...

Read More »

Wisconsin Oven Ships Gas Fired Batch Oven to the Aerospace Industry

Wisconsin Oven Corporation announced the shipment of one (1) Indirect Natural Gas Fired Batch Oven to a leading manufacturer in the aerospace industry. The batch oven will be used to cure composite materials. The batch oven has a maximum oven operating temperature of 500°F, work chamber dimensions of 10’ wide x 16’ long x 8’ high, and work zone dimensions of 8’ wide x 14’ long x...

Read More »

Thermal Product Solutions Ships Blue M Inert Gas Oven to Electronic Components Manufacturer

Thermal Product Solutions, a global manufacturer of thermal-processing equipment, announced the shipment of one (1) Blue M Inert Gas Batch Oven to a manufacturer of electronic components. This Blue M inert gas oven has a temperature range of 15°C above ambient to 593°C. The interior work chamber dimensions are 25” W x 20” D x 20” H. All seams and entrance ports in this batch oven were...

Read More »

Bench Oven from Grieve Comes with 300 CFM, 1/3-HP Recirculating Blower

Equipped with eight (8) drawers with dimensions of 6” W x 13” D x 6” H with removable insert to close around cord. Features 2 in. insulated walls, Type 304, 2B finish stainless steel interior and exterior. Includes digital indicating temperature controller, manual reset excess temperature interlock and recirculating blower airflow safety switch.

Read More »

Automation Streamlines Medical Kit Assembly

Automation technology is key to streamlining medical kit assembly operations. Our eBook delves into the benefits of automation, the industries it serves, and its role in COVID-19 response.

Read More »

Wisconsin Oven Ships Top Flow Conveyor Oven to Manufacturer In Machinery Industry

Wisconsin Oven Corporation announced the shipment of one (1) Electrically Heated Top Flow Conveyor Oven to a global manufacturer in the machinery industry. The oven will be used for curing “CPIG” material on plastic housings for electronic components. The conveyor oven has a maximum oven operating temperature of 200°C and work chamber dimensions of 2’4” wide x 21’0 long x 9 high....

Read More »

Thermal Product Solutions Ships Gruenberg Cleanroom Ovens to Medical Industry

Thermal Product Solutions, a global manufacturer of thermal-processing equipment, announced the shipment of six (6) Gruenberg Cleanroom Ovens to the Medical Industry. These Gruenberg unitized ovens has a maximum temperature rating of 149°C with work chamber dimensions of 26” W x 26” D x 34” H. The Gruenberg cleanroom ovens were constructed from a structural steel frame that supported the...

Read More »Excelitas Technologies to Feature New UV LED Curing Solutions at RadTech UV+EB 2016

Mike Kay Presenting “Improving Surface Cure with UVC LEDs” WHO:Ã- Excelitas TechnologiesÃ-® Corp., a global technology leader focused on delivering innovative, customized photonic solutions, will highlight its new UV LED curing products at RadTech UV+EB 2016 (Booth # 713). WHAT:Ã- Excelitas’ solutions meet the lighting, detection, optics and other technology needs of OEMs across...

Read More »

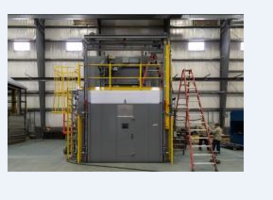

Batch Oven suits powder coating or finishing applications.

AvailableÃ- in 26 sizes, gas or electric Express Batch Oven (EBO) achieves temperatures up to 500Ã-

Read More »Baker Furnace Designs and Manufactures a 2200-

Yorba Linda, CA – Baker Furnace, Inc. is pleased to announce the shipment of a custom-built, high-temperature conveyor oven designed to heat treat rods used to manufacture commercial heating elements. The process also requires a nitrogen purge to create a specific atmosphere. At 35 ft long with an operating temperature of 1900Ã-

Read More »Challenge Accepted -LEWCO Engineers Design Unique, Compact, and Economical Conveyor Oven

SANDUSKY, OH – LEWCO, Inc. recently manufactured a custom conveyor oven for a repeat customer in the electric motor manufacturing industry.Ã- The customer had very tight space constraints and challenged LEWCO engineers to come up with an oven small enough to fit that requirement, while also achieving the required time and temperature for the parts. The result was a unique, compact, yet...

Read More »

Innovative Dampney Coating Systems Suit Even the Most Specialized Applications

Dampney's high performance coating systems provide protection against extreme weather, chemicals, and corrosive environments for atmospheric, immersion, and underground applications. Check out the video to learn more.

Read More »