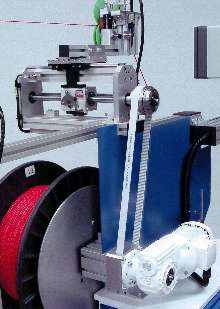

Linear Motion System simplifies machine setup.

Linear Motion Assembly is linked to production machine's main motor and does not require separate motor or controller to provide automatically reciprocating linear motion. Threadless shaft prevents clogging and jamming. Assembly offers axial thrust capacity to 800 lb, accuracy to Ã-

Read More »

Linear Motion Module uses toothed belt drive.

With lengths up to 5500 mm, CKR module achieves speeds up to 5 m/s with smooth running characteristics. External dimensions, accessories, and attachments are identical to company's CKK modules. Available motor mounting positions include front-mounted gear reducers and side drives with timing belt. Both options include various reduction ratios for adaptation of external mass to inertia of motor....

Read More »

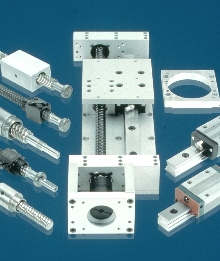

Linear Motion System offers choice of rails and drives.

EasyLinear(TM) Profiled Rail Stage System uses any brand of profiled rail. Drive options include multiple ballscrew leads, acme, hi-helix multi-start, lead screws with acetyl and polymatrix nuts. Accessories include motor mounts for C-Face NEMA, Oriental, and European metric motors. Hand cranks with locks and limit switches are also available.

Read More »

Design & Manufacturing Process of a Coil

Because the design and manufacturing of electromagnets are critical to the successful operation of the application, it's important to spend time defining your requirements before purchasing coils for an application. This eBook will guide you through the process of evaluating the application's constraints, identifying the needed specifications, and collaborating with a manufacturer to develop an appropriate coil solution for the application.

Read More »

What Can Test Devices Spin for You?

Test Devices helps you ensure the safety and efficiency of your high performance machines with cutting edge spin testing, rotor engineering, and precision balancing capabilities. Check out the video to learn more.

Read More »