Injection Machines use barrier screws for melt uniformity.

Maxima two-platen injection machines are available in 6 sizes with clamp force rating of 2,750-7,820 kN. Wide-platen configurations accommodate molds that normally require tie-bar spacing of larger machines. With footprint of 6,588 x 2,251 x 2,300 mm, smallest machine accommodates molds weighing up to 3,762 kg with 650 mm thickness, with tie-bar spacing of 915 x 660 mm and clamp stroke of 1,060...

Read More »

Injection Molding Machines range from 720-1200 tons.

Series em combines electric and hydraulic features for reduced cycle times. Two-platen mechanism provides accurate mold clamping, while linked split nut drive results in simultaneous actuation. Peakless Pressure Control eliminates high-pressure spikes at end of fill during high-speed injection. Long platen supports resist tilting and ensure parallelism of moving platen and mold. MAC-VIII control...

Read More »Injection Molding Machine has 3.5 sec total cycle time.

Model K-TEC 155 S, with hybrid drive and 1550 kN clamping force, is equipped with hydraulics and electric plasticizing drive. Automation system utilizes Heli-U 1700 clean-room robot, which inserts labels into 4-cavity mold that is directly injected over with thin-walled PP container. Extraction of container and insertion of new label occur in parallel during mold opening time of 0.9 sec. Compact...

Read More »Turning-Stack System produces multi-component parts quickly.

Turning-Stack System is based on rotary cube with 4 equal mold faces, arranged between platens of injection molding machine. After mold opens, pre-injected piece is held on cube and turned in steps of 90Ã-

Read More »

Rack System Design & Buyer's Guide

There is plenty to consider before setting up or replacing storage rack systems in your warehouse. This whitepaper contains a guide and general checklist of the most important considerations.

Read More »

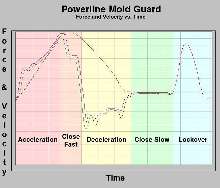

Injection Molding Machines provide mold protection software.

Mold Guard and Ejector Guard software, for Powerline injection molding machines, compare measured clamp and ejector forces to established force reference curves padded with alarm band. Programs stop component forward movement if measured force exceeds alarm band limits, preventing mold damage and premature mold wear. Both programs are ON/OFF selectable, and automatically compensate for force...

Read More »

Injection Molding Machine has artificial intelligence features.

All electric Si-B combines Fanuc's Alpha series servo motors and drives; reduced-inertia injection unit; and AI Ejector Protection, Mold Protection, and metering function for robotic consistency. Available in 4 sizes with 55-330 ton clamp force, product offers 0-300 mm/s injection acceleration times of 27 ms. Unit is suitable for molding thin-wall and precision parts. It is equipped with Windows...

Read More »

Vertical C-Clamp Machines have 130- and 280-ton capacities.

Magna V vertical injection molding machines (IMMs), based on C-frame platform, measure 15 x 7 ft. Vertical IMMs are available in stationary, shuttle, or rotary table versions. With 3-sided access, units provide tandem variable volume and fixed-volume pump systems, infrared light curtain, and XTREEM PC-based, open-architecture control. Units have maximum daylight of 35 in. and accept molds up to...

Read More »

Insert Molding Machine minimizes floor space requirements.

Vertical C-frame Evolution 280 measures 15 x 7 ft. and has no cage of tie bars around mold area. Available in stationary, shuttle, or rotary-table versions, it is based on 3-sided-access HC platform. C-frame also includes infrared light curtain and tandem variable-volume and fixed-volume pump system. The 280 ton version has maximum daylight of 35 in. and accepts molds to 24 x 36 in. Model 130,...

Read More »

Injection Molding Presses make dual, independent injections.

Presses make sequential or simultaneous injection of 2 materials, such as rubber, liquid silicone, or thermoplastic elastomers. Machines work 3 ways: 2 consecutive shots into adjacent cavities; simultaneous or sequential shots into single cavity; or simultaneous shots into 2 separate cavities. Onboard PC controls operation of dual injection heads, closing/clamp unit, and all other electrical,...

Read More »Accumulator Head features spiral diverter.

Design of Sterling Blow Molding accumulator head offers optimal parison wall distribution by balancing delivery of material around head. Streamlined flow channels and elimination of stagnation points enhances head purgability, resulting in faster color changes. Overlapping spiral geometry minimizes temperature and flow variations while eliminating knit lines within finished product.

Read More »

Ensure Your Medical Device Meets Regulatory Standards with Triad's Custom Magnetics

Triad Magnetics' custom components for medical devices are designed and manufactured with the strictest regulatory standards in mind. Our capabilities include rapid design, prototyping, and testing of inductors, transformers, and power supplies for medical equipment. Check out our video to learn more.

Read More »