Injection Molding Machine molds thin-wall parts.

Series MEII instantly reaches maximum injection speeds to accurately mold thin-wall and fine-precision parts. It utilizes belt-less electric injection drive servomotor and synchronous control. On-board hydraulic power unit allows for adjustment of nozzle force and power swivel of injection unit. Series MEII is available in 350 and 450 metric ton models with variety of injection unit sizes to meet...

Read More »

Injection Molding Machine produces structural parts.

Lumina 1600, for multi-nozzle, gas-assist injection molding, allows flexible production of large single and multiple parts. It has low-pressure injection and sequential injection capability and shot capacity of 11.4 kg. Clamping force is 335 metric tons. The 90 mm extruder processes 362 kg/hr. Platen is 1,370 x 1,778 mm with 64 nozzle locations.

Read More »

Vacuum Rubber Injection Machine eliminates trapped air/gas.

Using proprietary vacuum molding system, Vacu-Jet(TM) eliminates/minimizes entrapped air and gas that cause defects in molded products. Press utilizes FIFO system that ensures proper residence time for material and shot consistency. Available with injection capacities of 500-10,000 cc and clamping forces from 100-1,500 tons, machine features IPS Control System for process control and monitoring....

Read More »

Blow Molding Machine offers tie-barless accessibility.

Shuttle Blow-Molding Machine, Model BW F4 can be configured for single or double stations, each allowing 1, 2, 3, or 4-parison molding of bottles ranging from 0.2-1.5 l capacity. Machine accepts molds up to 12.40 x 10.63 in., while providing 11.02 in. horizontal shuttle stroke and 5.91 in. max daylight opening. PC-based controller includes touch-screen interface, Windows graphic display, bus...

Read More »

No Pencils Required: From Thinking to Knowing Through Mobility

This ebook provides a detailed guide on how mobility and digital data management systems (DDMS) can increase your company's overall effectiveness and efficiency.

Read More »Blow Molding System produces large containers.

With 4,500 lb/hr of barrier extrusion capacity, Series III 60-cavity blow molding system combines 6-layer coextrusion, all electro-mechanical clamp systems, and bottle handling capabilities. Rotary machine consists of wheel system with output and cavitation sized for few thousand to over 20,000 bottles/hr, with any material or layer configuration. In-mold labeling, dehumidification, and...

Read More »

Injection Molding Machine features 4,400 ton clamp force.

Metric Maxima 3900 has global, dual-platen design that occupies 18.5 x 54.8 ft footprint and offers optimized daylight area of 165.3 in. Unitized on injection and clamping base components, IMM design accommodates 2 injection units for co-injection or multi-material molding and utilizes single pancake cylinder for clamp tonnage. It features 607 oz. injection unit, 134 in. clamp stroke, 30 in./sec...

Read More »

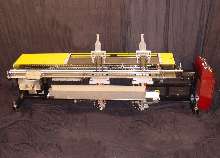

Takeaway Detabber System suits blow molding industry.

Model 2001E works with shuttle type blow molder machines including Bekum 120, 121, 151, 155 and Fischer 054 and 106. Detabber and grippers virtually eliminate jams. Machine operates on 120 Vac single phase power and requires Ã-½ in. compressed air line with 90-100 psi. Container sizes range from 5-12 in. in height and 1.25-6.85 in. in depth. Production rate is based on production rate of blow...

Read More »

Injection Molding Machines meet accuracy requirements.

All-electric, Series MEt features RASMA-L frame, which suppresses vibration and holds accuracy to micron levels. Rigid clamping mechanism and double-roller supported, movable die plates promote precision. Super Resin Control-II ensures constant metering, while PLCS-10 control uses LAN for accurate communication between controller and servo motor amplifiers. Configurations range from 35-300 tons...

Read More »

Injection Molding Machine is offered in 1,125 ton version.

Powerline 1125 employs wide-platen configuration to accommodate multi-cavity molds and large parts, while 50 in./sec clamp speed and pre-inject capability reduce cycle times. With 2-stage injection unit with maximum shot of 220 oz, unit is available in 70 and 120 mm feedscrew diameters. Maximum injection pressure is 35,000 psi. Direct-connected, rack-and-pinion clamp drive has 31 in. stroke...

Read More »

Blow Molding Machines offer PC-based closed-loop control.

Tracker accumulator-head models T-1000, T-2300, and T-2900 employ PC-based XTREEM XP control and noise-immune fiber-optic cabling. Proprietary Quality Tracking Software provides closed-loop control on parison push-out speed and accumulator head refill. Units handle part lengths to 120 in. and part weights to 100 lbs, while offering plasticizing rates to 3000 lb/hr. Modular components enable...

Read More »

Locon Sensors Withstand Extreme Temperatures

Locon Sensor Systems offer robust sensor solutions for even the most severe environmental conditions. Their line of high-temp inductive sensors and their cylindrical photoelectric series can operate in temperatures up to 250 degrees Celsius. See our video to learn more.

Read More »