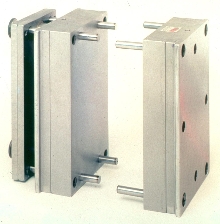

Mold Inserts include multi-purpose post.

Master Unit Die (MUD) Enhanced Series Mold Inserts have guide ejection system design, maximizing available insert core and cavity surface area. Guidepost retains and guides ejection system, and provides support without additional support pillars. Inserts are available in popular 08/09 insert thicknesses. They come with 4 leader pins, bushings, and return pins. Parting line plates are...

Read More »

Electric Aviation and a Sustainable Future

This white paper provides an in-depth overview into electric aviation and a sustainable future.

Read More »

Material Handling Solutions from Global Leader in Rubber & Urethane Power Transmission

Megadyne's QST polyurethane timing belts take up less space and guarantee a lower noise level than chain and other traditional material handling belts. Check out our video to learn more.

Read More »