Stainless Steel Mixers produce uniform emulsion.

Aqueous Mixers blend chemicals with water automatically for uniform emulsion at any proportion. All-metal units have no moving parts and require plant water line pressure of 25 lb. Fingertip control allows fine adjustment of mixing ratios from 3:1 to 100:1. Models are offered in stainless steel, brass, or nickel-plated and are rated at 3 or 10 gpm. They accommodate 5 gal pails, and 15, 30 or 55...

Read More »

Drum Mixers are gear-driven.

Mixers incorporate heavy-duty clamp mount that allows 90Ã-

Read More »

Agitator suits difficult, high-viscosity applications.

Heavy-duty, double-motion, scraped-surface No. 9M handles gums, gels, pastes, and similar products with viscosities as high as 2,000,000 cps. It includes piggyback motors for independent speeds, inclined shaft, and variety of turbine/crossbar and spacing designs. Units are offered in tanks and kettles for vacuum/pressure and special sanitary applications.

Read More »

Mixer suits research and development applications.

Process Pilot(TM) features modular, belt drive system that connects servo-motor and mixing chambers, allowing each mixer to operate at identical tip speeds. Double mechanical seal allows use with processes requiring high pressures, or containing highly abrasive solids. All contact surfaces are 316 stainless steel. Process Pilot offers 4 interchangeable mixing tools, 3 stages, and 6 mixing head...

Read More »

Quick Guide to Components for Medical Furniture

When designing for a hospital environment, it is essential to consider the small components that enable your application to perform to a high level. Hospital furniture has different users, so it's not only patients you need to think about, but also caregivers.

Read More »

Mix Heads offer integrated shot counter.

Suited for polyurethane processing, mix heads include counter to help identify at what point (number of shots) mix-head performance is impaired by abrasion. Counter displays exact number of times the mix head cycles to allow users to map out trends and historical data, aiding in gauging preventive maintenance.

Read More »

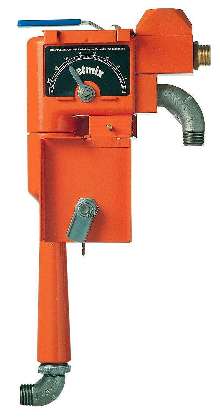

Coolant Mixer delivers accurate concentration of oil droplets.

Jetmix-® utilizes mixing-zone design, which creates strong shock waves of water vapor to break down coolant concentrate into highly homogenous emulsion of submicron size oil droplets. Resulting machining fluid provides stability, tramp oil rejection, and cutting-zone lubricity. Mixer is drum or wall mounted and connects to any tap water outlet providing 20-90 psi.

Read More »

Paddle Mixer mixes and hydrates sticky materials.

Twin Rotor Hydramix operates in continuous flow without clogging. Self-cleaning design features close tolerances between rotor paddles and container walls to reduce material buildup. Unit has adjustable mixing speed and provides production rates up to 10 tons/hr. Rotors operate at 10 rpm, preventing particle damage during residence times of 20-30 min. Applications include hydration of phosphates...

Read More »

Variable Speed Mixer handles high viscosity materials.

Hand-held Model EHR23/1.2R is equipped with galvanized paddle that can mix concrete, mortar, and epoxy in batches up to 176 lb. Variable-speed, 100-275 rpm motor eliminates splash back. Ergonomic handles ensure comfortable operation and protect mixer motor from dirt. Paddle has helical design that mixes batches from bottom up, preventing splash and keeping air from being sucked into material.

Read More »

Mixing/Flushing System cleans retention basins.

Hydroejector acts as mixer when basin water levels are high and automatically becomes flushing device when water levels are low. Unit ensures that all solid materials are resuspended and flushed as basin is emptied, eliminating need for manual cleanup. To avoid clogging problems, pump is equipped with self-cleaning N-impeller. Ejector pipe removes organic matter from basin and features large...

Read More »

Aeration/Mixing System eliminates dead spots in tank.

FloGet provides mixing and simultaneous aeration of all types of liquids. It incorporates submersible pump, air suction tube, and ejector/diffuser nozzle. System is suitable for any type of tank regardless of size, shape, or depth. Using different ejectors, FloGet can perform different tasks, including oxygenation, CO2 neutralization, sludge recycling, ozone treatment, mixing, foam suppression,...

Read More »

Precision Machined Parts for High Tech Applications

For precision and value that sets the standard for quality and craftsmanship, EGS Production Machining is the source for precision and value. Our extensive capabilities and dedication to customer service allow us to deliver the optimal manufacturing solution. See our video to learn more.

Read More »