Molding/Potting Compound is used to produce burner nozzles.

Thermally conductive, silicon carbide-based Ceramacast(TM) 673N can be used in applications with temperatures to 2,450Ã-

Read More »

Flame Retardant Epoxy is UL-94V-0 approved.

Rigid cure epoxy, EP-211FRHTC (Flame Retardant High Thermal Conductivity), offers thermal conductivity and flame retardancy. When cured at room temperature, it has service temperature of up to 130Ã-

Read More »Epoxy Compound works in bedding and casting applications.

Clear, flexible TRA-BOND 3010 bonds to ceramics, glass, most metals, and many plastics. It exhibits near-zero shrinkage and is resistant to water, weather, gases and vapors, petroleum products, mild acids and alkalis, salt solutions, and other organic compounds. Compound is suitable for aerospace and electronics applications.

Read More »

Safe Seal Materials protect drinking water systems.

Sealing materials meet NSF Standard 61 protecting potable water from contaminants that leach or migrate into water from traditional components. Organic materials include 10 EPDM compounds, 7 thermoplastic elastomers, and 2 nitrile compounds that can be formed into faucet and shower gaskets, water filter gaskets, valve seals and seats, pipe coupling seals, and diaphragms and O-rings used in pumps,...

Read More »

A Definitive Guide to Air Gaps in Magnetic Separation Equipment

This guide discusses how air gaps affect magnetic separation applications.

Read More »Custom Compounds produce speckled parts.

Speckled Dyneon(TM) Custom PTFE Compounds are produced by mixing PTFE with inorganic or organic fillers, which improve wear and abrasion resistance, reduce deformation under load, and add color. Compounds are offered in free-flow and pre-sintered grades. Speckled parts feature temperature resistance up to 500Ã-

Read More »

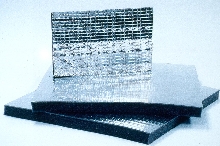

Composite blocks engine heat and noise.

TUFCOTEÃ-® RM-10-75 3-layer composite works as noise barrier and heat reflector for engine-driven vehicles and equipment. It has 3/4 in. urethane foam decoupler, lead-free vinyl barrier, and top facing of aluminized, scrim-reinforced polyester. With barrier toward noise and heat source, barrier contains noise, and shiny reflective facing reduces heat transfer. Scrim reinforcement limits...

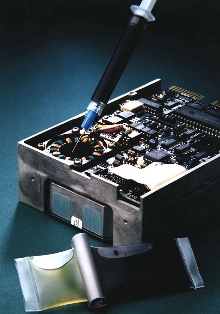

Read More »Epoxy Compound features one to one mixing ratio.

Type 20-3650 electronic grade epoxy potting, casting, and encapsulating system exhibits excellent physical, thermal, and electrical insulation properties. Tensile strength is 11,000 psi and compressive strength is 15,500 psi. Compound is DOT non-hazardous, easy to mix, and will cure at room temperature or with mild heat. Operating temperature range is -60 to +150Ã-

Read More »

Injection Molding Compounds resist impacts, chemicals, and fires.

Fire rated Kydex(R) compounds include 10 injection molding and 20 extrusion grades carrying fire ratings of UL Std 94 V-0/5V, FAR 25.853 (a) and (d), ASTM E-162, ASTM E-84, UL 723, UL 2043, UL 756C and/or Class 1/A. Also available are UL 705-rated grades meeting above-the-ceiling air plenum smoke release requirements. Compounds have impact resistance to 18 ft-lb/in., tensile strength to 6500 psi,...

Read More »

Casting Compound suits embedding and casting applications.

Flexible TRA-BOND 240-2 low-viscosity, polyurethane-casting system, suitable for low-vacuum applications, is NASA outgassing approved, and has near-zero shrinkage, providing low residual stress. Compound bonds to ceramics, glass, metals, and many plastics. Fully cured adhesive acts as electrical insulator.

Read More »

Purging Compound removes barrel residue in a single purge.

Utilizing reactive chemistry, NuPurge Technology (NPT) Compound performs at all temperatures between 160 and 600 deg F. It consists of concentrated purge pellets that react chemically to heat, quickly cleaning machinery without extra soak time. NPT requires no mixing or preparation. It is non-hazardous, FDA compliant and free of harsh odors.

Read More »

Industry Leading OEM with over 65 Years of Experience

Blonder Tongue Laboratories provides ISO 9001:2015 certified electronic contract manufacturing services at our on-site lab. We specialize in video distribution, fiber optics, and communications but have a variety of services available to bring your products to market. See our video to learn more.

Read More »