Multi-edge Milling Cutter features positive cutting action.

Featuring double-sided design with total of 14 cutting edges per insert, CoroMillÃ-® 745 is suited for face milling in large batch productions. Cutter offers 3 pitch versions: radially compensated MD pitch for when vibration is a factor, M pitch for general applications, and H pitch with higher number of teeth for higher productivity. Tilted insert positioning system in tip seat and...

Read More »DMI Event to Highlight Mazak Innovations that Boost Job Shop Efficiency

FLORENCE, Ky.,Ã- – Mazak distributor Dependable Machine Inc. (DMI) will host an open house at its new technology center in Hayden, Idaho, May 10-12 from 10:00 a.m. – 4:00 p.m. (PDT). The event will feature Mazak technologies that simplify part production processes as well as enhance shop floor productivity and versatility. A must-see for attendees will be Mazak’s MAZATROL SmoothX CNC....

Read More »

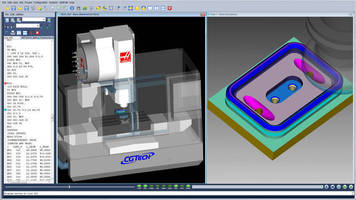

VERICUT Helps Grade Turning and Milling SkillsUSA/NIMS Contest Submissions

Irvine, CAÃ- - CGTech will be on hand at the National Leadership and Skills Conference (NLSC), June 21-23, 2016, to help grade multiple SkillsUSA/NIMS events related to Computer Numeric Control (CNC) machining. CGTech will also be exhibiting its latest version of VERICUT software in Booth S149. More than 16,000 peopleÃ- - including students, teachers and business partnersÃ- - will be...

Read More »Indexable Inserts, Grades enhance turning and milling options.

Designed for rough forging and castings, HR2 chip breaker featuresÃ- positive, stable geometry. Single-sided inserts are suited for working in steels, cast irons, and stainless steels. Also available, double-sided NMR chipÃ- breakers are designed for stainless steel operations. Wiper inserts W-FM and W-NM have positive front land for smooth machining. While T9226 grade suits heavy...

Read More »

Key Considerations for Basic Die Cutting: Tooling, Costs, Material Behaviors, and Tolerances

Key considerations to keep in mind when evaluating die cutting as your process of choice for part production.

Read More »

Solid Carbide End Mills suit high-feed milling applications.

Available with 2-, 4-, and 5-flute options, respectively, AlTiN-coated SN 200R/400R/500R Series features defined radius that helps direct radial cutting pressure axially up into tool holder and spindle, increasing metal removal rates in deep pocket and long reach applications. SN200R offers cutting diameters from .063–.500 in. in 3xD, 5xD, and 7xD lengths, while SN400R spans .125–.500 in. in...

Read More »Desktop CNC Tool uses standard 120 V power.

With 36 x 24 in. work area, ShopBot Desktop MAX can fit items such as guitars,Ã- chair and table parts, and cabinetry parts. Tool is used in prototyping and full production for cutting, carving, machining, and milling in wood, MDF, plastics, foams, and non-ferrous metals. Featuring dual-motor gantry design, tool offers 2 options for beds: aluminum deck or plenum with universal hold-down...

Read More »

Mazak Presents its HYBRID Approach to Additive Manufacturing at RAPID

Company combines additive and subtractive processes with multi-tasking part processing FLORENCE, Ky.Ã- - Mazak firmly established its position at the forefront of additive manufacturing with the development of HYBRID Multi-Tasking technology, which the company will present at this year’s RAPID Conference and Expo. The event takes place at the Orange County Convention Center in Orlando,...

Read More »

Mazak to Spotlight Accurate, Affordable Milling and Turning Solutions at TECMA

FLORENCE, Ky. –Ã- At TECMA 2015, taking place March 3Ã- - 6 in Mexico City, Mazak will spotlight accurate, affordable machine tools in Stand 430 that will forever change how machine shops process small and medium-sized workpieces for a variety of industries. During the show, Mazak will run part cutting demonstrations on the VERTICAL CENTER UNIVERSAL 400A 5X, VERTICAL CENTER NEXUS 510 5X...

Read More »

Solid Carbide Thread Mills help boost productivity.

With thread depths ofÃ- 1.5 x D and 2 x D, respectively, Walter Prototyp Supreme TC610 and TC611 offer geometry that minimizes vibration while producing optimal surface finishes, and through coolant design that maximizes chip removal and helps prevent fractures. WB10RD grade, providing optimized wear resistance, features TiALN coating with finishing layer of ZrN. WJ30RC grade, with TiALN...

Read More »

GMTA News of Note

Ann Arbor, Michigan – GMTA (German Machine Tools of America) represents various top-quality German metalworking machine builders, including Wera Profilator, K + G, Pittler, Praewema and WMZ, as well as Arnold lasers and Rosink parts washers.Ã- These machines are sold to the North American market exclusively by GMTA, primarily for gear and spline production, as well as other power...

Read More »

Come Alive Organics' Premium Organic Agave Provides a Healthier Choice

Come Alive Organics distributes all-natural, proprietary flavored agave for the food and beverage industry while helping children across the globe. Learn more about our agave products and our one sweet cause in this video and two-page PDF.

Read More »