Benchtop Machining Mill fits small and medium size tasks.

Prazi II PF7500 Series Model F1210E is available in 2, 3 and four axis CNC versions. Compact mill includes dovetail column with square ways for rigidity on 11 in. Z-axis. Mill head swivels 180 deg, while mill head spindle has infinitely variable speeds of 180-7500 rpm, 1.6 hp 220V air-cooled motor, and forward and reverse rotation with constant torque. Mill has 2.85 in. dia quill, MT2 spindle...

Read More »

Milling Cutters offer consistent cutting edge.

Aerostell(R) 5182 VZ pocket milling cutters with SFZ grade inserts are designed for roughing aluminum and finishing aluminum, pH stainless steel, cast iron, and high temperature alloys. They offer extended tool life due to sub-micrograin carbide, and wear resistance due to insert hardness, ground surface finish and edge preparation.

Read More »

Face Cutters have hexagonal inserts.

Hexamill 220.66 is suitable for medium to heavy-duty face milling applications. Face milling cutters have strong, thick inserts with 6 cutting edges that enable feed rates in excess of 0.020 in/tooth. Also available are cassettes to accept inserts, and CM cutter body can be fitted with cassettes to cut at depths of more than 0.315 in. Cutter is available in both normal and close pitch versions....

Read More »

End Milling Cutter provides light depth of cut.

Nano Turbo is designed for small-diameter endmilling operations including slotting, ramping, rough- and finish-contouring, and plunging. It offers light to moderate depth of cut (.20 in. and under). Available in range of cutter sizes from .375 to 1.5 in. dia, Nano Turbo utilizes 2 to 10 inserts to provide high metal removal capability. Inserts feature large wiper flat for good surface finish.

Read More »A Complete Guide to Aerospace Metal Fabrication eBook

Check out this eBook to learn all about aerospace metal fabrication - materials, processes, and applications.

Read More »

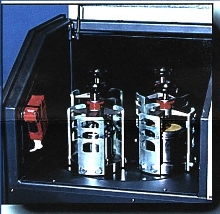

Ball Mill grinds to sub-micron dimensions.

PM 400 Planetary Ball Mill processes up to 8 samples without contamination, grinds material to sub-micron fineness, and has maintenance-free drive. Grinding sets are available in 4 sizes and 6 different materials. Superimposed motion of grinding jars, relative to central wheel, achieves high grinding efficiency. Generated energies by impact and friction of grinding media (beads) permit mixing,...

Read More »

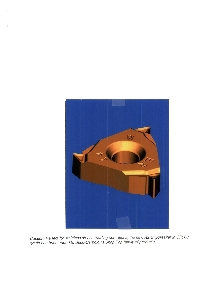

Threading Tool handles stainless steel.

Snap Tap A2 chipbreaker in CP500 grade minimizes vibration without compromising chip flow, can be used with all in-feed methods, and is available in external and internal A2 profiles for stainless steel threading operations. It has wear-resistant PVD coating, tough micrograin substrate, and high-positive cutting geometry.

Read More »

Machine combines shearing, press-braking, and rolling.

TRI-FAB Model 52P features shearing and rolling capacity of 52 in. x 12 ga mild steel and press braking capacities of 12 ga at 36 in. and 14 ga at 52 in. Machine will cut stainless steel up to 0.072 in. Rotating shafts are journalled in bronze bearings, and shear blades are Grade T10 tool steel. Manually-operated back gauge is standard, and can be positioned for use with shear or press brake as...

Read More »

Circulation Attritor can adapt to existing Q machines.

QL circulation grinding Attritor includes holding tank that is typically 10 times Attritor size. Specially configured arms speed up grinding and create more agitation. Unit's high circulation/pumping rate consists of holding tank contents passing through Attritor at ~8 times an hour. Grinding media for QL range in size from 3/32 to 1/4 in. in diameter. Typical media include chrome steel,...

Read More »Milling Cutters work fast and efficiently.

Fix-Perfect aluminum milling cutter inserts have on-edge orientation and 34 deg positive rake angle. This geometry reduces insert edge buildup, improves tool life, and provides free cutting action that makes it possible to machine thin-walled parts. Inserts are available in uncoated, coated, and polycrystalline diamond versions.

Read More »

Custom Fabrication & Machining Services with Over 30 Years of Experience

As a trusted manufacturer to customers across a broad range of industries, Key Gas Components is a premier provider of CNC machining and tube fabrication. Our entire organization is quality driven and customer-centric, with broad-based manufacturing capabilities that can accommodate the most challenging requirements. See our video to learn more.

Read More »