Ball-Nose End Mills are designed for punishing cuts.

Suited for rough milling and semi-finishing operations, ValMILL(TM) V440 Series ball-nose cutters have 2-flute design with one insert per flute and additional insert along tool shank that provides protection for larger cutter diameters. Multi-tooth end mills perform contouring, produce peripheral cuts, slot, drill, and mill die and mold cavities. Products, offered in 6 diameter sizes from .625-2...

Read More »

Colloid Mill is fully adjustable during operation.

Z-Series Sanitary Colloid Mills produces ultra-fine particle size reduction and sub-micron dispersions and emulsions of varying viscosities. Milling head requires no special assembly tools, and rotor/stator gap adjustment, isolated from process area, is fully adjustable during operation. Featuring 316 stainless steel construction with VitonÃ-® O-rings, mill is available with flow rates from...

Read More »

Plunge Milling Cutter is designed for metal removal.

Designed to provide high metal removal rate and chip evacuation, 7791VS series utilizes Z-axial cutting force. It is efficient in both roughing operations and deep cavities, and process minimizes tool deflection and side forces. Available in 1.5-6 in. and 40-125 mm dia, construction materials include steels, cast iron, aluminum, alloys, and high-temperature alloys. Product is suited for aerospace...

Read More »

End Mills remove chips in aluminum applications.

Blizzard(TM) series end mills feature 2-flute design and are available in regular and stub lengths. Square and various corner radii are also available. End cut gash and offset teeth permit large depths of cut and maximum feed per tooth. With 1 in. dia, end mills deliver clean cuts at feed rates of 450 ipm and speeds of 9,000 rpm. Slotting operations on stub length tools can be performed at axial...

Read More »

Guide to Fatigue Testing

Learn what fatigue testing is and how fatigue testing service providers can determine the longevity of a part or product.

Read More »

High Feed Milling Cutter suits die and mold industry.

TWINCUT Feed features 3-edge insert that maximizes chip thinning, resulting in feed rates up to 400 ipm. Unit runs at chip loads up to .125 in., and since it cuts at bottom of tool, as opposed to diameter, cutter can work at overhangs of 10 in. or more. TWINCUT Feed performs face milling, pocketing, and 3-D contouring in all steel up to 45Rc, 300, and 400 series stainless steels, and grey and...

Read More »

Face/End Mills generate 90-

ValMILL(TM) V590 Cutters accommodate ramping and helical interpolation. They eliminate secondary machining operations that are required when producing 90Ã-

Read More »

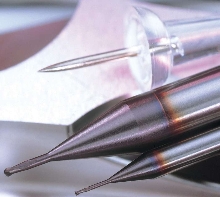

Miniature Rib Milling Cutters handle difficult material.

Hanita square- and ball-nosed end mills, designed for mold and die machining, cut materials such as graphite and steels hardened to 60 Rockwell C at speeds to 150 m/min. Offered in 4 series, Diamond Like Coating or TiAIN coatings are available. Hanita Vision end mills, designed for machining hardened steels up to 67 Rockwell C, operate at speeds to 200 m/min. They give surface finish of 63Ra and...

Read More »

Face Mills increase productivity.

Series KSOM Octagonal Insert Face Mills are Ã-¼ in. thick with Ã-¾ in. inscribed circle. Tool-steel insert pockets are machined in hardened state so they won't deflect. Face mills can be fed at up to 0.030 in. feed per tooth. Screw and finger-clamps keep inserts from moving under extreme cutting forces. Ranging in diameter from 2.5-6 in., units provide 8 cutting edges per insert, 22Ã-

Read More »

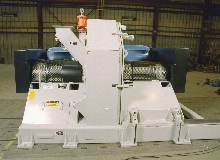

Cage Mill offers 2-4 or 6-row design.

Series H Multi-Cage Mill comes in 4 sizes up to 250 tph. Air cannons are mounted at intake and discharge to help prevent build-up of wet sticky material, while heaters are installed on grinder housing to retard buildup of wet material. Hydraulic ram eliminates gear head motor and rack and pinion used on other cage mills. Selective-crushing, controlled-impact mill sizes minerals, agglomerates,...

Read More »

Knife Mill grinds coated tablets for analysis.

Grindomix GM 200 is able to grind 20 gelatin-coated tablets in a few seconds, providing homogenous sample for analysis. It features feed size of 10-40 mm and produces final fineness down to approximately 0.3 mm. Parameters can be set for reproducible results. Grindomix GM 200 is particularly suitable for grinding larger tablets and plants with high fat or moisture content.

Read More »

Triad's Next-Gen Power Supplies Offer Increased Reliability and Reduced Noise Performance

Triad Magnetics, an established leader in power supply design and manufacturing, is proud to announce their next generation WAU AC and WDU DC Series of power supplies. These linear wall plug-ins offer minimum noise performance without sacrificing reliability or life. See our video to learn more.

Read More »