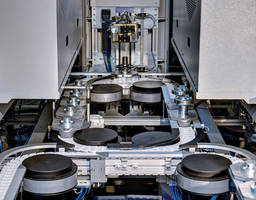

Vertical Turning DUO Cell

The machining concept of vertical pick-up machines as a modular system meets manufacturing companies' requirements for more quality, while simultaneously maintaining high flexibility and reducing cost. The right-hand and left-hand versions of the EMCO Maier VT 160 and VT 250, when linked with one of three basic conveyor options -- oval, meander, and crossover-meander designs -- provide a complete...

Read More »

PMC-Colinet Streamlines Huge Pipe Keyway Machining with Unique Angle Head from Heimatec

Ohio manufacturer of oil field equipment saves 184 hours on one high-precision cutting tool head made of NitralloyÃ-® PMC-Colinet has a long history in the pipe and tube market, having started in 1912 and introduced the world's first carbide-tooled pipe threading machine in 1958.Ã- Today, the company is established as a primary supplier of machines to the OCTG sector.Ã- Ã- Its...

Read More »

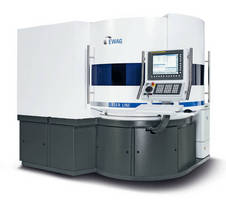

UNITED GRINDING's Vast, Advanced Technology to Stand Out at GrindTec 2014

Company to display several new innovations from WALTER, EWAG and STUDER in Hall 7-7050Ã- MIAMISBURG, Ohio – UNITED GRINDING, the largest single-source provider of complete and integrated grinding solutions, will showcase its latest grinding, eroding, laser and measuring innovations for general purpose and advanced tool and cutter production in Hall 7-7050 at GrindTec, taking place March 19...

Read More »

Nanotech Demonstrates Most Flexible Diamond Turning System

During SPIE Photonics West 2014 in San Francisco, Nanotech will demonstrate what has become their true flagship machining system. The Nanotech 350FG is the most diverse ultra-precision machine available. Starting with a minimum of three ultra- precision axes, it is easily expandable to five axes via optional B & C rotary axes. Typical applications for this machine include axisymmetric machining...

Read More »

Benefits of Interfacing Robots & People in the Supply Chain

Learn how robots generate safer operations, more accurate data, and greater flexibility.

Read More »

Pipe Beveling Tool End preps offshore piping systems.

Designed for dry-cutting high-temperature, high-pressure pipe from 4.5–18 in. OD, MILLHOGÃ-® Dictator Welding End Prep Tool features 3 hp air motor designed for operation in environments that have dirty air and high moisture content. ID clamping pipe milling machine develops 4,100 lb-ft torque at cutter blade and pulls continuous thick chips without cutting oils. TiN-coated blades dissipate...

Read More »

Hurco to Launch Nine New Machines Plus Software Enhancements

As MACH 2014 is the first national machine tool exhibition in the UK since Hurco redesigned its entire range of machining centres and lathes, every model on show in Birmingham will be new. The company will demonstrate six machining centres and two CNC lathes sporting the latest logo and livery, plus a representative model from its agency range of high-speed machining centres manufactured by...

Read More »

Robot Machining Cell universally adjusts to different tasks.

With installation size of 1,800 x 1,800 x 1,800 mm, RoboBox Machining Cell combines 6-axis articulated arm robot by StÃ-¤ubli in closed production module with 7.5 kW water-cooled milling spindle. System features slotted table, 8 tool positions, and anti-collision protection. Robot does not have to be conventionally taught; all kinematic movements are programmed using Mastercam Robotmaster...

Read More »

Mitsubishi EDM Moves into Additive Manufacturing with Matsuura Partnership, LUMEX Avance-25

Wood Dale, IL – MC Machinery Systems, Inc., wholly owned by Mitsubishi Corp., proudly announces its partnership with Matsuura Machinery Corporation, Fukui City, Japan, in introducing the new LUMEX Avance-25 metal laser sintering hybrid milling machine to the North American marketplace. The recent additive manufacturing boom is reaching fever pitch in North America. Meanwhile, Matsuura's laser...

Read More »

Rough Face Milling Cutter features multi-edge design.

Available in 4-10 in. dia, CoroMill 357 is suitable for roughing and cubing in steel and cast ironÃ- on ISO 50 and larger machines. Double-sided, pentagonal inserts are housed in shim-protected tip seats, and cutter body has insert clamping system that facilitates and accelerates insert indexing. Taking depth of cut up to 0.394 in. with feed per tooth up to 0.0276 in./z, cutters feature...

Read More »Maclan Corporation Increases CNC Capabilities

Lakeland, FL - Maclan Corporation, a longtime leader in the polyurethane and rubber products industry, has made major investments in new machinery that allow them to meet the increased demand for their products, which range from roller coaster wheels to rubber linings and dredge hoses. We have dramatically increased CNC turning capabilities, said Maclan spokesperson Maegan Wallace.Ã- With...

Read More »

Simple Connection � MGB with EtherNet/IP

The new MGB with EtherNet/IP is a leap forward in access door safety. Designed for easy installation, flawless performance, and long service life, it is engineered with robust features and cutting-edge technology that places it firmly at the leading edge of the door safety device industry. To learn all about the benefits of the Euchner MGB, see our video.

Read More »