Machining Centers feature cast iron construction.

Suited for milling large parts and molds in variety of materials, Model RH33 offers XYZ travel of 78 x 33 x 28 in. while Model RH35 offers travel of 120 x 35 x 30 in. Both machines feature open frame construction and are available with various accessories including automatic tool changers, chip guards, and No. 40 or 50 spindle. Base to saddles are supported by several box ways to maintain...

Read More »Roller Mill is designed for chemical applications.

Model 88 Chemical Gran-U-Lizer(TM) eliminates unwanted fines and provides uniform particle size utilizing continuous roller-style grinding method. Able to reduce waste and eliminate downstream classification systems, machine can be constructed with materials from carbon steel to stainless steel to meet corrosion resistance and contamination requirements. Applications include super absorbent...

Read More »

Inserts machine gummy, non-ferrous, and steel materials.

ValTURN(TM) Turning System tools include 3 top form geometries: M8, R4, and C2. Double-sided inserts of ANSI Negative type geometry come in various shapes and thickness, offering 98 specific performance options. Used in continuous and interrupted cuts, M8 suits medium machining applications. Heavy-duty R4 is designed for roughing of steels and cast irons, while positive cutting land on C2 ensures...

Read More »

Utility Cutters utilize square shoulder insert edges.

Utility Cutters maximize effects of APET and XPET Inserts by utilizing areas not typically used in 90Ã-

Read More »

Specifying Removable Insulation Blankets - A Guide for Engineers

Looking for guidance on how to spec removable insulation? Download our free guide for engineers now!

Read More »

Disc-Style Coffee Grinders provide grind uniformity

Utilizing Platinum Series Burrs(TM), Series GPX Grinders produce batch sizes as small as 1 lb, and are designed to grind 350-600 lb/hour. Dial allows selection of any desired coffee grind, with end result being ability to achieve full range of grinds for variety of coffee production applications.

Read More »

Fine Grinding Mill prepares samples for pelletizing/fusion.

Featuring all-digital controls, Bead Mill MM 301 prepares batches of various samples to 40-60 micron fineness required for XRF/XRD and other spectral analyses results. Device homogenizes powder with wax, flux, or other binders prior to pelletizing or fusion technique. Grinding sets, available from 1.5-50 ml in metal and non-metal materials, enable typical grinding time of 2 min. Bench-top unit...

Read More »

Screen Classifying Cutter controls particle size range.

Model SCC-30 Cutter cuts hard, soft and fibrous materials into controlled particle sizes. Helical rotor with cutter blades attached to array of interconnected parallelograms continuously shears oversize materials against twin, stationary bed knives. Suited for coarse grinding of materials into particles ranging from granules down to 20-30 mesh, cutter has 30 in. throat width and can be fitted...

Read More »

Machining Centers provide high-speed metal removal.

Millac 44V and 44H Vertical and Horizontal Machining Centers feature flame-hardened box ways, 10-tool magazine, and spindle speed of 12,000 rpm. Millac 44V offers X, Y, Z travels of 22.05, 16.14, and 16.14 in., respectively, while Series 44H features X, Y, Z travels of 16.14, 18.11, and 18.50 in. Suited for large complex part production, Model VTM-80YB provides vertical turning and milling in 5...

Read More »Machine offers mid-sized solution for hard-milling.

Featuring 23.6 x 14.1 in. work table in 79 x 110 in. footprint, HC-548EX Super Hybrid machine employs 3-point leveling base casting, monoblock riser, and bridge casting. Its 200-32,000 rpm integral motor spindle is equipped with HSK-E40 tooling and Fanuc 16iMB series control. Smooth interpolation of Super PCIII function allows machine to reach rapid traverse rates of 1,200 ipm. X, Y, and Z axes...

Read More »

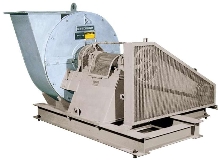

Cage Mill de-lumps and dries materials in one step.

Constructed with completely welded shell, cage mill with flash dryer handles temperatures up to 1200Ã-

Read More »

ISO-Certified Precision Machining and Contract Manufacturing Services from DFF

DFF is an industry leading contract manufacturer specializing in medium to high production precision machined components and electromechanical assemblies. Our 100 CNC machining centers and design-assist capabilities ensure our customers' needs are always met. Check out our video to learn more.

Read More »