Wireless Platform helps build power-efficient mobile networks.

Delivering scalable performance to contend with data growth driven by smartphones, tablets, and cloud-based services, AxxiaÃ-® combines cores from ARMÃ-® with hardware accelerators from LSIÃ-®. Resulting SoC is suited for building intelligent, heterogeneous networks. Embedded intelligence helps identify traffic, recognize applications, and deliver appropriate content at proper time....

Read More »Portable Foundry Wheels reduce grinding time.

BlueFire(TM) zirconia aluminum portable foundry wheels are designed for foundries, welding shops, fabrication facilities, steel mills, and shipyards. Wheels are available in 4NZ, NZC, and NZAC for steel and dirty, scale-covered castings. An extended cutting capacity requires less operator time to remove material. Wheels are available in stock sizes from 4/3 x 2 x 5/8-11 to 6/4-13/16 x 2 x 5/8-11...

Read More »

DME to Display Wide Range of Engineered Hot Runner Solutions at NPE

Learn how DME can be your most complete partner in mold technologies at booth #2803 Madison Heights, Mich. - DME Company, a leading manufacturer of mold technologies, will be presenting a wide range of its hot runner products at NPE 2012, booth #2803. For over 30 years, DME has offered a full spectrum engineered solutions essential for hot runner applications - everything from unitized valve...

Read More »

Hydraulic Breaker can match frequency to ground conditions.

To promote efficiency in demolition and rock-breaking applications, DXB260H features 2-speed control of breaker frequency for adjustment between short and long stroke settings. Product weighs 5,400 lb and delivers up to 600 blows/min. It is designed for use with excavators in 27-37 metric ton range. Rated in 8,000 lb-ft impact energy class, breaker requires hydraulic flow rate from 39.5-63.5 gpm....

Read More »

Everything You Need to Know About Cold Chain/Temperature Controlled Packaging

This ebook provides an overview of everything you need to know about cold chain and temperature-controlled packaging.

Read More »

Drying System is used on water-cooled extruded products,.

Powered by ACI variable-speed, multi-stage blower, LINE-Dry System removes residual moisture film from water-cooled extruded products up to 25 mm dia at speeds of 500 m/min. Enclosed version has one pair of facing air delivery plenums that can be adjusted to suit different product dimensions and are sprung to allow flexing to accommodate product distortions/kinks. Open version consists of 2 pairs...

Read More »

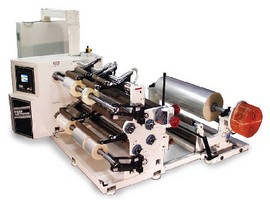

Duplex Slitter/Rewinder Ideal for Metalized Films and Foils

Model SR7000 slitter/rewind is designed for thin gauge films at low tensions. (Neenah, Wis.) - The Model SR7000 Duplex Slitter/Rewinder from REM is designed for thin gauge films, foils and packaging materials. Capable of running 84-inch wide webs at 1500 FPM, the SR7000 model can handle 48-inch diameter unwind rolls while producing 24-inch diameter slit rolls at rewind. Pull rolls are placed...

Read More »Goodrich to Showcase Advanced Defense Technology at AAAA Show

Real-time intelligence, mission data, and condition-based maintenance solutions enhance aircrew safety and readiness CHARLOTTE, N.C., April 12, 2011 - Goodrich Corporation (NYSE: GR) will showcase a broad array of advanced military technology at next week's 2011 Army Aviation Association of America (AAAA) annual forum and exposition, taking place April 17-20 at the Gaylord Opryland Convention...

Read More »

W.S. Tyler Certifies Test Sieves to New ASTM E 11 Standard

Mentor, Ohio-W. S. Tyler now performs examinations to certify that Test Sieves conform to the new ASTM E 11 Standard for Inspection and Calibration Grades. W.S. Tyler's Optical Analyzer is calibrated, ensuring the measurements are directly traceable to N.I.S.T., on a bi-annual basis. Certification documents that include detailed histograms are supplied with both new and in-use test sieves. The...

Read More »Plasma Treatment System optimizes PCB yield.

Designed for manufacturing high density interconnect, flex, and rigid panels, ProVIA(TM) requires minimal floor space. Vacuum system, plasma chamber, control electronics, and 40 kHz power supply are housed in single enclosure. Full front and rear access allows for service to all interior components, and no side access is required. Pump is positioned on rollers to facilitate removal.

Read More »

DoorKing's 1601 Lane Barrier Provides a Higher Level of Traffic Control for Less

DoorKing is proud to introduce an easy add-on to its 1601 Barrier Gate Operator: The 1601 Traffic Lane Barrier. The barrier gate provides greater traffic control while eliminating the need for bollards or crash beams. Check out this video to learn more.

Read More »