Sewage Grinder targets wastewater pump stations.

Measuring 13 ft tall, Channel Monster XD 3.0 produces 7 tons of cutting force at peak loads. System combines rotating screening drums and Muffin MonsterÃ-® grinder to shred solids while processing up to 59 million gallons/day. It features 15 hp grinder motor, 1 hp motor for drums, 3 in. hex drive shafts, and stainless steel coil drums with Ã-½ in. diameter rod. System is suited for pump...

Read More »

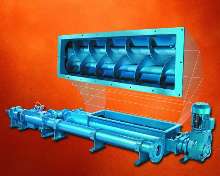

Grinding System suits extreme wastewater applications.

Combining rotating drum screens and Muffin MonsterÃ-® grinder, Channel MonsterÃ-® XD grinds difficult solids to manageable particle size, protecting downstream equipment and preventing pump blockages. Models with stack height greater than 32 in. feature 40000 Macho Monster grinder technology, with 2Ã-½ in. hex drive shafts and 7Ã-½ in. diameter cutters. Powered by 5, 10, or 15 hp...

Read More »

Wastewater Treatment Products suit municipal applications.

For close-coupled configurations, 2000 CC pump features sealed Ultra-DriveÃ-® universal gear-joint drive train and optimized rotor/stator pumping element geometry. Annihilator(TM) grinders are twin shaft solids reduction units with optimized cutter combinations and one-piece flange housing. Able to handle dewatered municipal sludge to over 50% solids, 2000 HS System features integral hopper...

Read More »

Screening Grinders suit wet, dry, or submerged applications.

Suited for heavy, solids-laden wastewater applications, TASKMASTER TM1600 Grinders process gravity or conveyor fed sewage screenings and provide in-channel grinding as well as bulk solids shredding. Twin-shaft Model TM1634 features 16 x 34 in. cutting chamber, right angle planetary gear reducer, and counter-rotating shredding mechanism employing cutter cartridges. Hardened alloy 2Ã-¾ in....

Read More »

Workwear Goes Hand-In-Hand with Employee Satisfaction and Retention

High-quality gear reminds employees that they are valued by their employer and improves their workday. To find out more about choosing the best workwear, download now.

Read More »

Grinder prevents maintenance of downstream equipment.

Self-contained Pipeliner(TM) Grinder eliminates ragging in secondary and tertiary sludge applications. Single-shaft unit features tungsten carbide adjusting cutters, spring-loaded cutter assembly that maintains constant force against shearplate, on-site cutter replacement without disconnecting piping, and single mechanical seal with silicon carbide faces. Standard shearplate hole is 15 mm, with...

Read More »

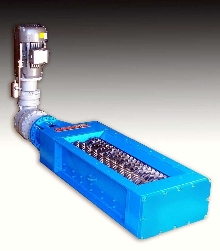

Grinder protects small pump stations and influent channels.

Channel MonsterÃ-® CMD1205-AD employs 5 in. diameter drum to direct solids into cutting chamber, allowing installation in channels as narrow as 14 in. Drums are available with either Ã-¼ in. coil spacing or Ã-¼ in. perforations. Grinder operates on 3 hp motor with 29:1 reducer and is available with optional 5 hp motor for difficult grinding installations. Applications include wet...

Read More »

Twin Shaft Grinder eliminates cutter stack re-tightening.

With TASKMASTERÃ-® TM8500, banks of individual cutters and spacers are replaced by 1-piece catridges. Cutters are installed on 2 counter rotating shafts, intermeshing at close clearance to shear and shred solids. All elements are machined from solid alloy steel or stainless steel. Suitable for inline, open channel, or gravity installations, grinder is useful in sewage treatment plants, sludge...

Read More »

Reduction Units offer optimized cutter combinations.

Featuring one-piece flange housing and quick-change cutter cartridge, Series 4 Annihilator(TM) Grinders are twin-shaft solids reduction units suited for industrial and municipal applications. Equipped with counter-rotating, intermeshing cutters and spacer cutters, grinders protect downstream equipment from being plugged or damaged from large solids.

Read More »

Rotary Grinders recycle wood and plastic waste.

Vertical Rotary Grinders operate at 120 rpm with 30,000 lb-ft of torque and noise level from 80 to 85 dB. Rotor shaft incorporates 1 3/4 x 11 in. solid steel discs, each pocketed to accept 3 knife holders. Knives are made from A2 tool steel to hardness of 60 Rockwell. Grinders have heavy-duty ram constructed of 5/8 in. thick top plate. Nylon glides and position adjustments eliminate...

Read More »

Trotec Laser Offers Customizable Industrial Laser Marking Solutions for Any Application

Trotec's laser marking solutions provide your company with configurable workstations and intuitive, customizable software. Check out our video to learn more.

Read More »