Belt Conveyor fits in restricted spaces under stamping dies.

Ultra Low Conveyor needs only 2 3/8 in. clearance under die, meeting restricted space requirements for die applications in stamping industry. It can be used to carry product or scrap from under die. Conveyor's re-belt unit requires as little as 1 in. clearance under die. Belt tension is easily adjusted while conveyor is in place. Optional features include electric or air drives, and choice of...

Read More »

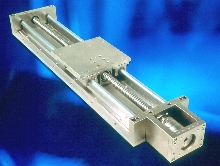

Linear Slide is corrosion resistant.

EasyLinear(TM) Slide utilizes TeflonÃ-® composite linear bearings, available in standard, high-load, high-wear, and food-grade ratings. Electroless, nickel-plated slide is available in diameters up to 1 in. and built with combination of electroless nickel-plated aluminum and 303 or 400 stainless steel components. All 303 stainless steel version is also available, in diameters up to 1 in., for...

Read More »

Belt Conveyor offers 4 flow patterns.

LAHR Steel Hinged Belt Conveyor can be custom built to meet production needs. Flow patterns include S, P, L, and Z, with belt widths up to 60 in. Lengths and inclines fit specific application. Options include belt material, coating, rigid or adjustable supports, and casters. Conveyor typically handles metallic chips and non-metallic waste from machining operations or scrap from trimming,...

Read More »

Vacuum Conveyors satisfy USDA requirements.

Vacuum conveyors, available with diameters of 21 and 56 cm, deliver capacities of up to 5 metric tons per hour. As all integral components fulfill USDA requirements, systems also fulfill US FDA guidelines. Conveyors' modular construction allows them to be adapted to meet users' needs. They are manufactured using ASTM 316L steel and employ filters that trap particles as small as 0.5 Ã-µm....

Read More »

Does an IT MSP Really Add Value to a Manufacturing Environment?

To find out more about how IT managed service providers can specifically help your manufacturing company, download now.

Read More »

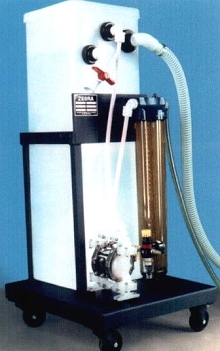

Oil Skimmer has stainless steel filter.

Snapdragon(TM) portable oil removal system is offered with stainless steel particle filter and coalescing media. Design allows operator to remove pure oil without wasting coolant. Skimmer features heavy-duty steel caster system and double-diaphragm air pump. It digests dirty coolant and tramp oils through intake hose and collects all unwanted contaminants in upper part of holding tank. A 100...

Read More »

Downdraft Tables comply with all clean air legislation.

Downdraft Tables capture dry dust from welding, grinding, deburring, sanding, polishing or cutting. They are self-cleaning and available in different dimensions. Options include backdraft hoods, welding enclosures, special grating materials, light kits, and water trays. Downdraft Tables filter air at source without operator participation.

Read More »

Bottle Carriers handle range of bottle sizes.

Bottle Carrier Handles are for single, 2, 3, 4, and 6 packs of beverages. All offer ample space for product stickers and can be supplied with printed UPC codes. Twin Pack Carrier Applicator is 36 in. wide by 48 in. long and can easily be integrated into any production line. It provides in-line speed of up to 25 cases per minute.

Read More »

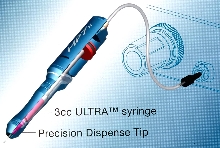

Dispensing Tool applies small dots of thick fluids.

Model HP7x multiplies dispensing pressure by 7-to-1 ratio, so that 100 psi of input produces 700 psi of air pressure inside disposable 3 cc reservoir within unit. Pen-like device connects to 100 psi air-powered dispenser and replaces standard syringe reservoir. Small dots are achieved by using ULTRA microdot dispense tip. To dispense controlled amount of material, operator holds HP7x like pen,...

Read More »

Miniature Linear Guides require little or no lubrication.

MicroGuide(TM) linear guides, with 440C stainless steel construction, have Gothic Arch ball-groove geometry for quiet, single-rail operation, and provide accuracy up to Ã-

Read More »

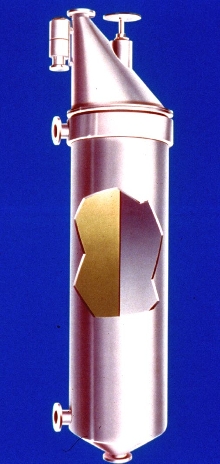

Purge Vessel dries and cools polymer pellets.

Purge vessel can be used as batch processor to dry and cool large mass of polymer pellets. Heated, dry air flows up through bottom of purge vessel while it is being filled with wet polymer pellets. As airflow continues, pellets are held under high volatile vapor pressure and low volatile partial pressure. When pellets are dry, vessel is purged with dehumidified air. In cooling phase, cool, dry...

Read More »

ISO-Certified Precision Machining and Contract Manufacturing Services from DFF

DFF is an industry leading contract manufacturer specializing in medium to high production precision machined components and electromechanical assemblies. Our 100 CNC machining centers and design-assist capabilities ensure our customers' needs are always met. Check out our video to learn more.

Read More »