Vertical Turning DUO Cell

The machining concept of vertical pick-up machines as a modular system meets manufacturing companies' requirements for more quality, while simultaneously maintaining high flexibility and reducing cost. The right-hand and left-hand versions of the EMCO Maier VT 160 and VT 250, when linked with one of three basic conveyor options -- oval, meander, and crossover-meander designs -- provide a complete...

Read More »

Finish Boring Head targets micro-machining applications.

Offered in diameters from ÃË.016-.276 in. with max through-tool coolant pressure of 300 psi, Series EWN 04-7 is intended for use on micro-milling machines with high-speed spindles such as HSK-E25, E32, or E40. ProductÃ- features high precision adjustment accuracy of .0005 in./ÃË and .0001 in./ÃË through use of Vernier scale. Available with Kaiser KA1 modular connection or...

Read More »Discover Mazak - Canada Event Aims for the Competitive Edge in Manufacturing

Florence, Kentucky - The Discover Mazak - Canada event at the Mazak Canadian Headquarters and Technology Center promises to be one that will give solid competitive advantages to those companies involved in manufacturing. As part of that opportunity, attendees will learn how to secure new work, gain useful insight into maintaining current work and discover how the Canadian Government can help grow...

Read More »OMAX Wins $3.75 Million GSA Order From The United States Air Force

Kent, Washington, January 14, 2009 - OMAX Corporation, the industry leader in abrasive waterjet machining, is pleased to announce the sale of 16 units of its 55100 JetMachiningÃ-® Center to the United States Air Force. The sale, estimated at $3.75 million, was completed in partnership with Phillips Corporation - Federal Division, OMAX's distributor exclusively dedicated to providing...

Read More »

The Advantages of Reshoring Your Manufacturing Operations

Bringing work back to the United States benefits your organization, customers, and the U.S. economy.

Read More »

End Mills meet micro machining application requirements.

Solid Carbide Micro End Mills combine geometrically optimized cutting edge and slim, concave, tapered neck to offer flexible capabilities in various materials from 66 Rc hardened steel to graphite. Available in 24 designs, these ball nose, torus, and flat end style end mills can be uncoated or have TiAlN coating. Cutting diameters range from .008-.080 in., with effective cutting...

Read More »Micromachining Laser enables in-house prototyping.

MicroMaster V5 UV excimer-based micromachining system utilizes ultra-short pulse length laser technology to cut, drill, and etch materials. Features include 4-6 nm pulse length, 193 or 248 nm wavelength output, 1 Ã-µm multi-axis workpiece positioning control, 200 mm square travel, variable apertures, debris-free gas nozzle, in-process beam quality monitor, and CAD/CAM compatibility. System is...

Read More »

Materials Processing Unit suits micromachining applications.

Developed for repairing flat panel displays, micro circuits, and wafers, Model IX-70 ChromAblate(TM) on-target inspection and short deletion system can be configured with IR, visible, or UV wavelengths to process materials from metals to polymers. Adjustable attenuator allows precise control of laser power. IX-70 incorporates co-axial CCD camera with adjustable zoom lens for alignment and...

Read More »

Air Driven Spindle suits micro machining applications.

With maximum speed of 80,000 rpm, Air Power Spindle can be used on existing machines as additional spindle. Thermal displacement in Z-axis remains constant at less than .001 mm, and when combined with Mega Micro collet chuck, spindle delivers dynamic run-out accuracy of less than .002 mm. Spindle is available in dual contact spindle types, including BIG PLUS CAT, BIG PLUS BT, and HSK

Read More »Kyocera's New Micro Tool Line Improves Performance in Plastics Micro Machining Applications

Drills, end mills plus technical assistance are the focus at booth E-2757 Irvine, CA. June 23, 2006 - Kyocera Micro Tools will introduce a new line of micro tools at the International Manufacturing Technology show Sept. 6-13 in Chicago. The line is designed for optimal performance in plastics micro machining applications. Visitors to booth E-2757 will find micro drills, end mills, engraving...

Read More »

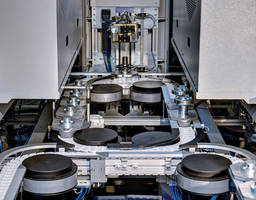

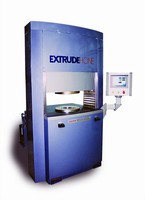

Extrude Hone Corporation to Unveil Next-Generation Process Controls for Abrasive Flow Machining (AFM) at IMTS 2006

Irwin, Pa. (June 2, 2006)-EXTRUDE HONEÃ-® Corporation announced today plans to unveil its next-generation process controls for Abrasive Flow Machining (AFM)- AutoFlow(TM) AFM-at the International Manufacturing Technology (IMTS) Show 2006 in Chicago, from Sept. 6 - 13. Extrude Hone representatives will be available at booth #7100 to discuss this latest AFM advancement, as well as the company's...

Read More »

Von Ruden's Driven Tools Are Built to Last

Von Ruden's driven tools are designed to each specific machine in order to maximize performance. All of our tools are performance tested and made in the USA per ISO 9001:2015 standards. Check out our video to learn more.

Read More »