Micro Machining Center operates with zero metal contact.

Model ZÃ-µ3500 uses temperature-controlled hydrostatic oil in hybrid spindle bearing, static pressure guides, and linear motor cooling system, virtually eliminating thermal distortion saturation time. At 25 hp, spindle reaches speeds of 30,000 rpm. Travels are 13.78 in X-axis and 11.8 in Y- and Z-axes. Positioning is accomplished with cooled scaled linear motors at 0.6 G in acceleration. Near...

Read More »

Micro-Machining System provides high-volume production.

Suited for micro-machining, drilling, and laser processing, IX-3000 Class 1 UV Excimer-based laser step and scan ablation system is surrounded by cleanroom enclosure with roof-mounted HEPA filtration. Mask imaging system operates at 248 or 193 nm UV wavelengths and offers 0.2-0.3 micron optical resolution, repeatability, and structural accuracies. Stages feature air-bearing design, and granite...

Read More »

Micromachining System offers submicron positioning.

MicroMill allows operator to draw precise patterns, cuts, characters, and holes on-screen and view work-piece throughout process. Submicron stage resolution on 3 axes allows accurate micromachining over 2 in. in all directions. Machine provides CNC and 3D digitizing capabilities and incorporates automated height gauge, stereomicroscope, and color CCD video camera. It comes with computer, flat...

Read More »

Machine cuts, cleans, and deburs -½-4 in. copper.

RIDGIDÃ-® 122XL reams Ã-½-2 in. tubing and, with optional quick-change fitting brush system and storage rack, prepares Ã-½-4 in. copper fittings for soldering. Product eliminates need to manually revolve cutter around tube and reduces number of tools needed on job site. Components include O.D. cleaning brush and deburring disk, heavy-duty cutter wheel, and cone reamer. Machine is...

Read More »

There's More to Plating than You Zinc!

To find out more about the seven demands you should make of your zinc plater, download now.

Read More »

Machining Center integrates multiple processes in one setup.

Variaxis 500 offers rotary table with A-axis tilting angle from -120Ã-

Read More »

Machining System allows choice of spindles and no. of axes.

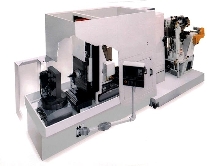

PB Plus(TM) modular precision machining system utilizes modular construction, which allows units to be implemented in stages. Each system is built around one or more standard modules, which consists of base with feed slide; enclosure; hydraulic, lube and electrical systems; CNC control; and chip removal system. Basic module has linear displacement accuracy of Ã-

Read More »

Machining Centers produce die, mold and precision parts.

Bridge-type HSM 400 is suitable for wet, dry, or graphite machining in tool and moldmaking industry. It has 7-position automatic pallet changer, tool magazines with choices of 18, 36, or 68 tools, and laser measurement system that monitors lengths and radii of tooling. Widely spaced guideways withstand forces of high speed machining. Spindle motors are liquid cooled with hybrid ceramic ball...

Read More »

Tabletop Machining System works on microelectronics.

Compact AccuLaze has Nd:YAG laser, video system and control software. It can be used for resistor and capacitor trimming, hole drilling, LCD repair, materials marking and etching, and semiconductor failure analysis including circuit isolation and polyimide and passivation removal. It is available in 6 wavelengths from deep UV (213 nm) to IR (1064 nm). This allows users to match wavelength to...

Read More »

Von Ruden's Driven Tools Are Built to Last

Von Ruden's driven tools are designed to each specific machine in order to maximize performance. All of our tools are performance tested and made in the USA per ISO 9001:2015 standards. Check out our video to learn more.

Read More »