Extrusion System produces complex automotive parts.

Metal Extrusion System consists of 2,000 ton stamping press equipped with computerized controls that adjust instantly to 100 different component designs. It combines stamping, deep drawing, and cold forming to produce fully integrated automotive components. Fasteners become part of single component, eliminating need for weld nuts, stamp-in nuts, and self-piercing nuts. Applications include...

Read More »

Glue Conveyor simplifies production-line packaging.

Automated, stand-alone system conveys consistent flow of thermoplastic adhesive pellets or chiclet-sized chips over distances of over 100 ft from bulk source to melter unit. Filters screen particle size of material flowing through line, minimizing foreign particle entry into melter unit. Able to feed single or multiple glue stations, it automatically responds to need for hot-melt glue using...

Read More »

Sizer suits coal mines, coal prep plants, and quarries.

Modular Mountaineer Sizer is 40 in. high and offered in various lengths. Arrangement of teeth on rolls is configured to customer requirements and can include straight rows, spirals, herringbone, and other designs. Crushing chamber is fully lined with wear plates to protect frame. Retractable, steel wheels enable relocation of machine for maintenance.

Read More »

Machine combines belt and edge-milling capabilities.

Constructed of cast iron, medium to heavy-duty Model 4500 sands, grinds, surface finishes, deburrs, chamfers, and bevels. Table tilts 45Ã-

Read More »

Inventory Management Services

This white paper provides an overview into the benefits, approaches and considerations for inventory management services.

Read More »

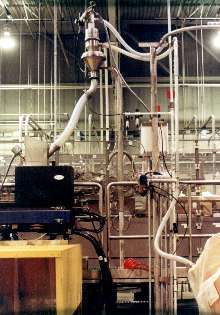

Film Machine runs at high speeds.

Large, 4 meter, cast film line processes industrial pallet stretch-wrap film at speeds from 1,470 to 1,960 ft/min, with outputs between 5,500 and 6,200 lb/hour. Faster cycle times eliminate off-line rewinding for hand wrap, and single roll handling system simplifies winding logistics. Process control system incorporates automatic die-control software and provides management reporting and recipe...

Read More »

Plate Compactors provide high force at high frequency.

Single-direction Models BOMAG BP25/48 and BP25/48D deliver 6,075 lb of centrifugal force at frequency of 5,400 vibrations/min. BP25/48 is powered by 5.5 hp Honda gasoline engine, while BP25/48D has 4 hp Hatz diesel engine. Wear-resistant base plates decrease amount of material pick-up and allow operators to turn units while compacting asphalt without scuffing work surface. Optional water...

Read More »Cut-Off Machine offers integral end finishing.

Model TCC-25 Rotary Tube Cut-off machine offers integrated double end finishing, which allows square or chamfered ends to be provided on one (or both) ends of tube. It allows operator to select desired cut type (thru cut, cut and pull, or end finished) from control panel. Lengths and quantities are user-selectable, allowing the machine to be programmed for automatic operation.

Read More »

Pipe Milling End Prep Tool has oversize ID clamping system.

Air-powered Commander MillhogÃ-® Model C-314 offers dual opposed tapered roller bearings for smooth operation. Oversize clamp ribs fit into pipe ID and have 6 contact points to spread radial load and minimize vibration. Fully portable, it pulls thick chip without cutting oils on pipe from 3.75 in. ID to 14 in. OD Providing 1 mandrel and 7 sets of clamps, model unit has 3 hp air motor that...

Read More »

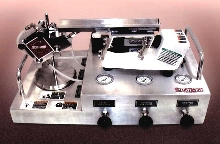

Tint Mix System matches any color with simplified tint set.

DynaMatch Tint Mix System allows finishers to meet application, VOC, and color requirements for small or large production orders without stocking expansive inventories. Using one set of 16 high-pigment loading tint pastes, system allows for accurate color matching via various bases, primers, catalysts, reducers, and additives. VOC base ratings range from 2.0 lb/gal to 5.5 lb/gal. Common bases can...

Read More »

Jet Mill suits 10 to 20 gram batches.

Qualification MicronizerÃ-® with 2 in. milling chamber, can mill up to 1/2 lb of material per hour, yet is capable of feed rates as low as few grams per hour with maximum sample recovery. Fines have narrow particle-size distribution, with particle diameters as small as few microns. Replaceable venturi allows mill to accept wide range of feed sizes, and peripheral feed design prevents...

Read More »

Precision Fabricating with Over 40 Years of Experience

Quality Sheet Metal specializes in delivering precision, value, and customer service. With a client base that spans many diverse industries and a reputation for excellence that goes back over four decades, our clients know that we can provide the optimal combination of value and flexibility regardless of the challenge. See our video to learn what we can do for you. Through investments in state-of-the-art design, manufacturing, and quality control systems, Quality Sheet Metal remains focused on maintaining a high standard of quality, customer service, and competitive pricing. With an emphasis on customer satisfaction, Quality Sheet Metal is dedicated to establishing long-term partnerships, similar to the ones they currently have with their valued clients. If you're looking for a new partner with extensive capabilities in sheet metal fabricating and finishing, look no further.

Read More »