Milling/Drilling Spindle targets Swiss turning applications.

Suited for compact tool zones in most Swiss Type machines, Model HT 25 S 60 delivers ultra precision with less than 2 microns run-out to enhance surface quality and machining accuracy. Compact unit measures 22 mm dia and 63.3 mm in length. Incorporating synchronous, DC motor technology, unit features high rigidity and suits machining applications including micro-milling, drilling tools,...

Read More »

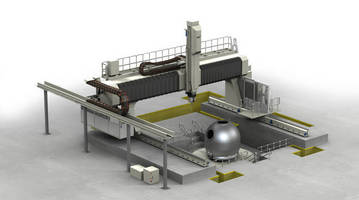

Universal Machining Center offers 5-axis, 5-side contouring.

Model U5-3000 system features Y-axis travel of over 20 ft, unlimited X-axis travel, and Z-axis ram with 20 in. cross section. Its 15,000 rpm contouring spindle delivers up to 42 lb-ft torque, while rigid box-way roller-bearing rail system and dual-motor rack-and-pinion X-axis drive offer precision and high thrust levels on long-travel cuts. System has feed rates up to 787 ipm, with continuous...

Read More »Universal Plastics Completes Installation of HASS Vertical Milling Machine

Provides streamline tooling for more competitive thermoforming of clamshell packaging Holyoke, MA - Universal Plastics has completed purchase and installation of a new HASS VM3 CNC Vertical milling machine. The milling machine is equipped with a 40 X 26 bed, 25 of vertical travel, and a 24 tool change. This machine combined with new CAD/CAM software allows us to direct machine tools for thin...

Read More »ATI Tool Changers Help Bring Ford's Fuel Efficiency Message to the Masses

Ford EcoBoost Display Showing at the New York Auto Show, April 2-11, 2010 Apex, NC, - When Ford Motor Company and ABB Robotics looked to create a new live robotic display to communicate the fuel efficiency message of Ford's new EcoBoost Powertrain Technology, they turned to ATI Industrial Automation for their Tool Changing needs. Debuting at the 2010 NAIAS Detroit Auto Show and on display at the...

Read More »

Injection Molding from 3D Printed Molds

Check out this white paper to see how 3D printing may be a beneficial alternative to traditional mold making processes.

Read More »Flexible Precision Toolholder for Tool Grinding

The precise prism toolholder type PRISMO clamps every shank diameter between 5 and 20 millimeters With its eroded prism guidances, PRISMO the toolholder for tool grinding from SCHUNK clamps different shank diameters with a repeat accuracy of less than 0.005 mm. Without any doubt, the PRISMO tool grinding toolholder from SCHUNK is one of the highlights of this year's GrindTec show. With its...

Read More »

MultiCam Announces New PowerMax/High Definition Combination Plasma Head

Dallas, Texas MultiCam Inc. announces a new option for its popular 3000 and 6000 series CNC plasma machines. Our combination plasma features a Hypertherm Powermax 45 mechanized plasma head mounted next to an XD 130/260 high-definition Hypertherm torch. Each head is independently programmable resulting in a CNC plasma system that can economically cut gauge steel using low amperage consumables...

Read More »

Normac's MX17 Seven Axis CNC Universal Tap Thread Grinding Machine

The MX17 is a completely new 7 axis Universal Thread Grinding Machine With CNC wheel dressing capabilities specifically designed for the manufacture of ultra precision taps and threaded components. Features Heavy duty cast polymer base to dampen vibration. Hydrostatic slide ways on all axis for the highest level of stiffness. Direct drive grinding wheel spindle with an automatic wheel balancer...

Read More »

SR77: Absolute Magnescale-®

Slim type magnetic scale system that outputs position signals for machine tools and other equipment that require high-precision positioning. Compatible protocols include: FANUC, Mitsubishi, Matushita and Yaskawa o Measuring Length(ML): 70-2,040mm o Accuracy : 3+3ML/1,000 Ã-µm p-p, 5+5ML/1,000 Ã-µm p-p o Maximum resolution : 0.01 Ã-µm o Maximum response speed : 200m/min. o Protocol :...

Read More »

Universal Knife System performs multiple tasks in one setup.

Using one main rotary drive, Techno Universal Knife System is capable of processing multiple applications through interchangeable heads. System can change between Oscillating Knife, Tangential Drag Knife, Spring Loaded Pen, Vinyl Drag Cutter, or Creasing Wheel Kit when needed. When combined with Techno Vision digital image verification package, system provides complete digital finishing solution...

Read More »

Standex Engraving Mold-Tech Offers Nickel Shell Capabilities on a Global Scale

Standex Engraving Mold-Tech is the premier, global supplier for mold texturing and surface finishing. With a full range of services, Standex Engraving Mold-Tech is also the only nickel shell supplier producing in three global locations. See our video to learn more.

Read More »