EDM Drilling Machine provides precision in graphite milling.

Roku-Roku GR-658N Super Hybrid features 12-position tool changer, 5-position decimal input, 320 MB flashcard with Ethernet protocol, and 32,000 rpm spindle. Full enclosure confines dust to machining area, keeps it suspended via intermittent air blasts, then evacuates it. Dual way and steel ball screw covers protect against excessive machine tool wear. Pneumatic counter balancers provide smooth,...

Read More »

Rotary Indexer offers 24 V control with self diagnostics.

Requiring 23 x 8 in. of bench space, Toggle-AireÃ-® Model 2000LC, 6-station rotary indexing machine features low-voltage control system with fully adjustable operating parameters. Pneumatic press offers ram repeatability and ram-to-station accuracy of Ã-

Read More »Linear Guides work in single or multi-axis systems.

Suited for tough working environments, quadÃ-®-linear units EVT ensure fast, precise run in single- or multiple-axis systems. Products consist of anodized aluminum profiles with integrated guide table driven by protected drive mechanism. Internal prism guide ensures silent and maintenance-free run. Products are offered in 2 versions: spindle drive EVT-S with ball screw, and drive belt EVT-Z....

Read More »Horizontal Machining Center allows 24/7 production.

Model HS5000 is equipped with SEICOS 18M CNC control and 30 hp peak direct-drive spindle, which accelerates from 0-14,000 rpm in 1.4 sec. High axis acceleration rates along with 1 sec tool-to-tool time yield chip-to-chip time of 3.2 sec. Changing 19.7 in. square pallets takes 6 sec, even when loaded with max payload of 1,102 lb. Triple trough construction uses center conveyor that moves bulk of...

Read More »

The Ultimate Guide to Packaging Automation Solutions

This ebook provides an in-depth guide to packaging automation solutions.

Read More »

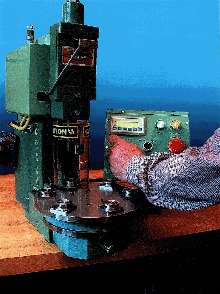

Orbital Forming Machine assembles non-rounds.

Benchtop Model T-321 can flare oval, square, rectangular, D- and Double-D shaped pins, posts, and shafts. Non-round machined, semi-pierced, diecast, or molded tabs and bosses can be formed to secure mating parts. Form tools on machine maintain constant line contact with workpiece without intermittent peening motion. Speed and heading pressure are infinitely adjustable. Work stroke is selected for...

Read More »

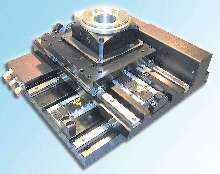

Positioning Platform is suited for 300 mm wafer metrology.

Featuring 3-plate design and direct-drive rotation, ISM300 low-profile, integrated XY-Theta positioning platform achieves total surface access on 300 mm wafers. Maintaining constant orientation of patterned elements on wafer relative to measurement optics, integrated metrology platform achieves linear speeds to 300 mm/sec and combined XY-Theta repeatability of less than Ã-

Read More »

Tooling System increases plunging and copy milling capability.

Minimaster System, for machine diameters from .250 to .750 in, includes replaceable carbide inserts for slotting, square-shoulder milling, drilling, center drilling, chamfering, and copying. Clamping system, where indexable carbide insert is mounted in shank, allows quick and easy changing of inserts. Three-flute ballnose for copy milling provides 5 times metal removal rate of conventional steel...

Read More »

Rodless Rail Slides feature enclosed bearing system.

Series SFP is available in 27 and 40 mm bore sizes with linear travel lengths up to 3,400 mm in 25 mm increments. Stainless steel outer band and saddle scraper seal enclose bearing system and continuously protect internal mechanisms from contaminants. Body incorporates side slots for mounting of reed and solid state switches. Units include adjustable cushions for smooth deceleration at end of...

Read More »

Injection Molding Machines meet accuracy requirements.

All-electric, Series MEt features RASMA-L frame, which suppresses vibration and holds accuracy to micron levels. Rigid clamping mechanism and double-roller supported, movable die plates promote precision. Super Resin Control-II ensures constant metering, while PLCS-10 control uses LAN for accurate communication between controller and servo motor amplifiers. Configurations range from 35-300 tons...

Read More »

Powder Compacting Presses suit hazardous environments.

Equipped with intrinsically safe control system that is able to handle hazardous class 2, Division 1 work environments, 200 ton explosive powder hydraulic presses offer automated operation. They have 4 independent rams, 2 down and 2 up-acting, with precision control over ram speed due to bi-directional flow control.

Read More »

Error Proofing by Design

Sturtevant Richmont's torque tools help customers cut rework and warranty costs while increasing throughput.

Read More »