Cutting and Grooving Tool has 3 cutting edges.

Secured by a unique clamping solution, CoroCut 3 uses its third cutting edge in shallow parting of tubes and bars and grooving operations. Its parting widths of .079, .059, and .039 in. help reduce raw material usage, while its 2 dedicated insert geometries help ensure peak performance and quality of surface finish in all workpiece materials. Same holder can be used for all insert widths.

Read More »

Dip-Flux Feeder facilitates flip chip assembly.

Dip-Flux Feeder picks up component from waffle tray, stick feeder, or tape feeder, then dips component, leads, or BGA balls into rotating flux bath. It then places component or flip chip onto board or substrate. Fixed squeegee in rotating flux bath ensures constant flux wave height. Laser sensors detect approaching components and halt squeegee rotation for duration of dipping process. Feeder is...

Read More »

Hydraulic Press offers 24 in. stroke.

One hundred ton hydraulic press is used for trying out variety of dies for forming, stamping, and draw applications. It offers small bolster footprint of 24 x 24 in., and includes 0-20 ton bed cushion with 6 in. stroke. Built-in decompression hydraulics are provided for stamping operations. Dynamic Force Control allows for zoned control of cushion and ram forces during draw applications.

Read More »Bucket Blade Scraper is made of 100% recycled rubber.

Rubber Bucket Blade Scraper uses adjustable-slide channel, allowing heavy-equipment operators to adjust position of bolts within channel to match existing bolt pattern on plow. Rubber sections, reinforced with tough plies of nylon and steel, are compressed onto 1Ã-¼ in. steel rod and secured every 12 in. using flatbar retaining plates. Adjustable heel pads help level scraper and extend life...

Read More »

Construction Materials for the Future

In this eBook, we highlight some key advantages of Cross-Laminated Timber (CLT) and show why every builder needs to consider adopting this remarkable construction advancement. We'll also introduce you to the latest innovation in CLT, GRIPBlock™, an exciting new technology that will change the way you look at CLT forever.

Read More »

Curcular Saw uses cold cutting technology.

Equipped with Cermet-tipped blades, 8 in. Metal Cutting Circular Saw produces spark-free wake and cool, burr- and scorch-free edges that do not require post-cut finishing. Powered by 13 A, 3,700 rpm motor, it can cut through Ã-¼ in. plate material and has 2 9/16 in. cut depth. Features include cut-depth adjustment lever, ergonomic soft-grip handle, stainless steel shoe, system of sight-line...

Read More »

CNC Machine combines turning, drilling, milling, and grinding.

Hardpoint 300 can be configured with up to 4 main spindles and variety of tooling combinations, depending on user needs. Number of axes is variable, with up to 10 possible. Machine offers fully automatic, synchronous complete cutting of complex workpiece geometries up to a diameter of 3 x 3 in. It can incorporate internal gantry loader to save floor space. External loaders are available, as well...

Read More »Tube Benders bend up to 1/2 in. tubing.

Models 370-FH and 371-FH Triple-Head Tube Benders feature offset handles that enable smooth, tight-radius 180Ã-

Read More »

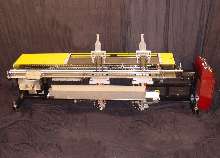

Takeaway Detabber System suits blow molding industry.

Model 2001E works with shuttle type blow molder machines including Bekum 120, 121, 151, 155 and Fischer 054 and 106. Detabber and grippers virtually eliminate jams. Machine operates on 120 Vac single phase power and requires Ã-½ in. compressed air line with 90-100 psi. Container sizes range from 5-12 in. in height and 1.25-6.85 in. in depth. Production rate is based on production rate of blow...

Read More »

Wafer Positioner offers integrated 3-axis tip/tilt stage.

Designed for 300 mm wafer processing, DynamYX GT air-bearing wafer positioning system offers 6 axes of precision motion control. Machine includes silicon carbide stage, single plane system architecture, and low-profile design that reduces center of mass to minimize error from deflection or angular deviation. Alignment is achieved via Z-Tip-Tilt stage integrated on carriage in non-contact design....

Read More »Milling Chucks offer high accuracy and gripping force.

U-Series Milling Chucks provide strong grip and rigidity through chucking mechanism that clamps cutting tool evenly up to 3 mm from chuck's nose. Thick wall and internal slots also create additional torque and rigidity. Chucks provide high accuracy with run-out of less than 5 Ã-µm at 100 mm from nose. Four sizes range from 0.750-2.000 in., however chucks can be converted for use with metric...

Read More »

Micro Air's Dust, Fume, Mist Collection Equipment Facilitate a Safe Work Environment

Dust, fume, and mist collectors from Micro Air promote a safer, more productive work environment. Our wide array of products are available to the industrial manufacturing sector for processes such as welding, cutting, grinding, blasting, and more. Check out our video to learn more.

Read More »