Machine Vision System completes test programs in 1 hr.

Optima 7210(TM) optical process test (OPT) system is designed for post-placement, inline defect detection, and process measurement. System utilizes built-in knowledge of SMD process and variation compensation. Based on Configural Recognition(TM) object recognition and image analysis technology, system provides non-contact testing with VARI-Smart(TM) image compensation software, which builds...

Read More »

Label Inspection System verifies label quality/placement.

iLabel checks for appropriateness, placement, angle, and quality of labels on bottles, boxes, cans, and packaged goods, issuing overall grade of pass, fail, or recycle for each label. Using neural network technology, product automatically learns variation in good labels and checks for flags, tears, and damage in subsequent labels. System inspects 300 labels/min with sizes from 1-10+ in. and is...

Read More »

Machine Vision Appliance inspects quality of labels.

Requiring only minutes of setup time, iLabel checks placement and quality of labels on bottles, boxes, cans, and other packaged goods. It detects flags, tears, and damage to label, and inspects each one for significant defects then reports measurements of quality, placement position, and angle. System inspects 300 labels per minute, from 1-10 in., issues grade of pass, fail or recycle, and...

Read More »

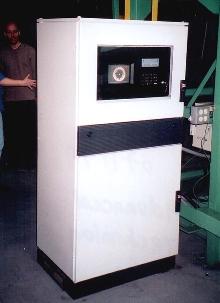

Inspection System is custom designed.

Automated Inspection Machine includes EZVision(TM) machine vision system with camera optics and lighting, plus necessary material handling needed for user's application. EZVision(TM) system includes application engineering for lighting, optics, and methodology inspection setup. Mechanical configurations vary, and include vision-guided robots, feeder bowls, part-positioning tracks, conveyors, and...

Read More »

Screen Printing vs. Digital Printing: Five Key Decision Factors

Learn about the key factors for deciding between screen printing and digital printing.

Read More »

Machine Vision System incorporates vision software tools.

Incorporated into VisionProÃ-®, geometric measurement tools measure distance between circles, points, and lines in ActiveX environment. Data analysis tools allow users to perform statistical analysis of vision tool results without having to first write custom programs, automatically computing various statistics to be analyzed over time. VisionPro systems offer QuickStart(TM) drag-and-drop...

Read More »

3D and 2D Inspection System scans devices in strips.

Automated model PPT861-SH(TM) provides precise measurement of critical device parameters. Utilizing SMI(TM) (Scanning Moire Interferometry(TM)) 3D technology, it allows 100% production inspection of devices in strips, including BGA, CSP, and LGA. All scanning and motion parameters are programmable. Typical measurements include coplanarity, ball height, surface flatness, and true position. Inline...

Read More »

Identification Systems automatically verify tires and wheels.

Identification systems ensure presence of correct tires and wheels at multiple process points. Model TIS-8000 provides in-process verification and identification of tires by recognizing tire treads and sidewalls. Model WIS-8000 recognizes wheel-spoke patterns, wheel finish, and other features. Both systems have 99.99% accuracy and include PatMaxÃ-® technology, PC-based machine-vision frame...

Read More »

Machine Vision System provides 50 full frames/sec.

Model VCM50 miniature progressive scan CCD smart camera is 100 mm long, 30 mm in diameter, and consumes less than 1 W. Sony CCD sensor features 640 x 480 pixel resolution and can read 7 to 10 ECC200 Data Matrix codes per second from full frame images. Process interface allows 2 inputs and 4 outputs for direct control of external equipment. NEMA4 housing stands up to vibrations, shocks, and...

Read More »Vision Guide features geometric search tool.

Vision Guide robot guidance system uses Geometric Search Tool to quickly locate model or multiple models at any position under harshest conditions. Tool finds parts with full 360Ã-

Read More »

Machine Vision System helps achieve 100% quality control.

SPECTRUM3 includes 11 1k x 1k frame buffers for over 92 Mb of pixel resolution in gray scale or full color. Dedicated vision engine inspects full resolution color images at over 10,000 parts per minute. Software allows system to set sensitivity levels automatically, virtually eliminating false rejects and scrap. Color monitor shows each part as it is inspected, complete with color highlights...

Read More »

New Davenport Hybrid Machine Offers Unique Flexibility for Parts Manufacturing

The Davenport Hybrid machine offers greater flexibility, easier set-ups, and faster cycle times. Check out the video to learn more.

Read More »