Label Applicator handles all types of cylindrical objects.

Designed to label objects from .5-10 in. diameter, Bottle-Matic Labelers apply labels at over 4.5 ips and can label over 1,000 pieces/hr. To operate, user inserts container and presses foot switch. System can handle most tapered containers by adjusting idle roller position. Dispensing tables, formed out of 6061-T6 aluminum, have hand milled peel edge that enables label dispensing without tearing...

Read More »

Printer Applicator unites packing slip and shipping label.

Equipped with 2 printheads, Uniwall Series TwinPrint Printer Applicator prints and applies both shipping label information and packing slip information on single label. Applicator is mounted above conveyor and prints and applies shipping label/packing slip to top of cartons at speeds up to 25 cartons/min. System comes standard with 16 in. OD label roll, dynamic tension control, positive-pressure...

Read More »

RFID Tag Inserter targets medium and small label runs.

Featuring tag dispenser with web tension relief, Model RFID-CP inserts UHF and HF inlays under die-cut blank or pre-printed labels and validates finished product. Control and monitoring is accomplished through pendant station which houses industrial PC. System works with transponders in accordance with ISO specifications, in widths from 20-80 mm. With inserter, pre-printed labels ranging from...

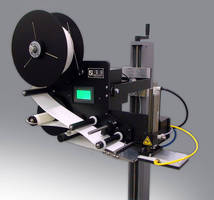

Read More »Label Printer Applicator features touch screen control.

Model LM3510 includes multi-featured touchscreen control platform, quick change tamp pads, and 15 I/O points for integration to other machines. Other features include dual-trigger input, 2 serial ports, encoder port, batch counter, job storage, and printer status output. Unit is programmed via HLI-100 handheld programming pendent or optional Smart Touch Screen Control, which can control up to 4...

Read More »

How Is Expanded Metal Foil Made?

Expanded metal foil is a lightweight coil of metal that has been slit and stretched to create a uniform mesh pattern of openings.

Read More »

Printer/Applicator handles multiple labels simultaneously.

Capable of applying labels to front, side, and back panels of pallets, 3-Panel Printer Applicator is suited for production lines requiring application of multiple labels to boxes or pallets at same point in production line. Unit allows operators to select label application to one, two, or three panels of pallets or cases.

Read More »

Pressure Sensitive Labeler handles up to 300 containers/min.

Featuring stainless steel and aluminum construction, Model 326 Auto-Colt III Trunnion handles round pharmaceutical and opthalmic containers measuring 0.563-2 in. in dia with shoulder heights from 0.813-3 in. System features servo-driven feedscrew and trunnion roll system for positive container handling and servo-driven label dispenser/applicator that provides accuracies of Ã-

Read More »

Automatic Shipping System handles small parcels.

Designed for envelopes, bags, pouches, and small parcels, ShipMaster 800 automates shipping process from point where cartons are packed. Belted system can scan order ID, weigh, print/apply shipping label, verify label, and manifest, all in about 10-15 ft of space. Typical system replaces 2-4 manual operators and processes 15-20 pieces per minute.

Read More »Inline Shipping System processes up to 20 cartons/min.

In about 10-15 ft of space, ShipMaster 900 can scan order ID, weigh, print/apply shipping label, verify label, and manifest. Able to replace 2-4 manual operators, system includes infeed/outfeed conveyor, automation center with PC-based controller, in-motion scale, fixed position order ID scanner, and fixed position label verification scanner, as well as scanner interface, CASI print and apply,...

Read More »

Label Applicator has PLC controls with touchscreen HMI.

Available in tamp, tamp/blow, or synchronous configurations, Model e300 features variable speed stepper motor that achieves speeds up to 1,000 in. of label web/min. Product includes touchscreen display, and angled U-arm cradle mount for top, bottom, and side applications. Constructed of anodized aluminum, rugged industrial-duty applicator is ideal for pressure sensitive label applications of an...

Read More »

Label Applicator comes with tamp module.

Featuring anodized aluminum construction for protection from corrosive environments, Model ST1000 applies various sizes and shapes of pressure sensitive labels. Top, bottom, and side applications are accomplished with angled U-arm for positioning of applicator head to product. With tamp module, Model ST1000 can be used for recessed areas, indexing lines, and variable speed lines. Additional...

Read More »

Precision Machining Solutions with Over 25 Years of Experience

Quality, customer service, and unbeatable value are the hallmarks of Hogge Precision. Since 1989 we have built a reputation as the go-to precision machining source, servicing many demanding industries. For CNC machining and screw machining, there are few manufacturers that can match our capabilities and expertise. See our video to learn more.

Read More »