Manncorp to Unveil New Stencil Printer and Vapor Phase System at IPC APEX Expo 2013

Electronic manufacturing equipment provider Manncorp will be unveiling several all-new products at IPC APEX Expo Booth #118 in San Diego, California, February 19-21. Among the new products will be a compact, touchscreen-controlledÃ- vapor phase soldering systemÃ- designed for the most complex, temperature-sensitive soldering and conductive adhesive curing applications.Ã- The...

Read More »

APEX FA On-board 3D SPI Featured in San Diego

SMT and process specialist Apex Factory Automation will showcase stencil printing with integrated 3D solder paste inspection at IPC/APEX. SJ Inno Tech, the successful Korean manufacturer of precision print systems for SMT and Solar technologies, produces the closed loop system. Its features and capabilities will be highlighted at booth #1117. With a worldwide installed base of over 1000 machines,...

Read More »

Bosch Presents Highlights from Processing, Inspection, and Isolator Technology

Equipment for solid and liquid pharmaceuticals -· Tablets: mixing, granulating, pressing and coating on a laboratory scale -· Compact inspection unit KKX 3900 for capsules -· Fast Air Lock ISS 100: quick transfer into and out of isolators At TechnoPharm 2013 in Nuremberg, Germany (hall 6, booth 235), Bosch Packaging Technology presents highlights from its comprehensive pharmaceutical...

Read More »Volkswagen Invests in Mobile Virtual Measurement Room from Creaform

LÃ-©vis, QuÃ-©bec - Creaform, leader in portable 3D measurement solutions and 3D Engineering Services, announces that the Plastics business field (BF) of major automotive manufacturer Volkswagen Group has fitted its plant in Wolfsburg, Germany with a virtual measurement room equipped with Creaform measurement technologies, as part of a pilot project. Launched in May 2012, the C-Link...

Read More »Are Starrco Modular Systems Right for Your Application?

Prefabricated construction is a type of construction method that involves manufacturing building components off-site or in a controlled environment

Read More »

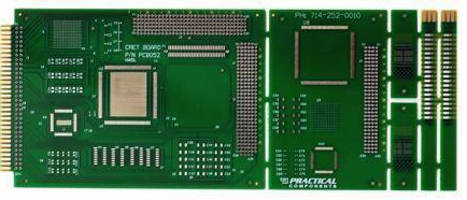

Practical Components to Offer Practical Products to the Cleaning Center at the IPC APEX Expo

Practical Components announces that some of its products will be featured by Bob Willis in the Printed Board Assembly Cleaning and Contamination Testing Center during the upcoming IPC APEX Expo, scheduled to take place February 19-21, 2013 at the San Diego Convention Center. Located in Booth #1549, the center will provide practical support to visitors keen to implement new cleaning and...

Read More »

Portable Diagnostic Camera features integrated illumination.

Designed to view and illuminate, FireSightÃ-® Diagnostic System enables color video monitoring and recording while inspecting inside of processing equipment under low light or dark conditions. Self-contained system consists of air filtration, power system, and 9 in. CCD color monitor. Air-cooled right-angle viewing lens and integrated 250 W lamp assembly is available in 36, 48, and 60...

Read More »JETVision: Increase Mailpiece Integrity and Quality with Industry-Leading Vision Technologies

Errors in the production process can seem almost endless. From duplicate pieces to items with missing information or poor quality, there are many challenges that can cost hundreds of thousands of dollars in wasted time, materials and potential penalties from missed deadlines. While manual quality checks can help alleviate this problem, they are time consuming and subject to error. Your business...

Read More »

Vision Sensor combines inspection and positioning.

Available in white or IR ring light option,Ã- Inspector PI50 contains expanded toolbox for object location and positioning based on taught-in pattern, free-form, and line/polygon object shapes. Unit also provides tools for quality inspection such as blob, pattern, edge, and pixel counting inspection. With Inspector PI50, users can build their own operator's interface with sensor's web API,...

Read More »Kistler at MEDTEC Europe 2012: 100 % Quality with Process Monitoring for Injection Molding, Assembly and Product Inspection

Injection Molding, Assembly and Product Inspection In-process quality assurance solutions made by Kistler Group have proven their high efficiency for applications in medical technology, diagnostics and pharmaceutical industry for years. At the specialist trade show MEDTEC Europe, which takes place from 13 through 15 March, 2012 in Stuttgart/Germany, visitors to the Kistler booth no. 4453 in hall...

Read More »

Flexcoat Opts for two ROTOCONTROL RSP Single Pass 100% Security Inspection Machines

Machines will benefit the Brazilian Converter's 100% inspection of pharmaceutical labels Ahrensburg, Germany - ROTOCONTROL today announced another two machines sold into Brazil to Flexcoat Produtos Auto-adesivos, a highly regarded company in the Brazilian Label Market. Ordered were two RSP Single Pass 100% Security Inspection Machines, subsequent to an on-site visit from Marcelo Zandomenico, of...

Read More »

5 and 13 Micron Resolve Columns with Greater Bed Stability

Jordi Labs provides materials solutions that set the standard for innovation and quality. Our line of GPC and GFC columns are on the cutting edge of precision manufacturing and a result of our uncompromising commitment to quality and customer service. See our video to learn more.

Read More »