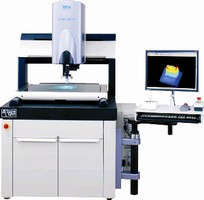

Metrology System speeds electronic assembly.

Equipped with digital megapixel cameras, 450 x 450 mm stage, and CAD-driven Elements software, non-contact Benchmark 450 provides electronic assembly process verification. BLAZE(TM) continuous image capture feature captures multiple images as part continually moves beneath system optics. Using library of pre-configured component routines to automatically create measurement programs from CAD...

Read More »

Measurement Station provides non-contact inspection.

Featuring built-in electronics, motorized zoom optics, and high-resolution color camera, self-contained StarLite(TM) System provides 6 x 3 x 5 in. XYZ capacity to accommodate critical parts and tooling. System has cast aluminum base and column, and uses white light LED VectorLight(TM) and backlight illuminators for optimal imaging. Additional features include 1 micron resolution linear scales,...

Read More »Inspection System provides semiconductor design verification.

Portable Verifier HR X-Ray System addresses failure analysis, quality inspection, and measurement applications, while VIPx Image Processor provides Windows(TM)-based toolbox of image enhancement/filtering, analysis/measurement, and reporting tools. Together, products offer solution for inspecting and measuring electrical connections and intra-package characteristics. Verifier HR features 90 kV, 5...

Read More »Laser Scanner digitizes space into 3D, action-ready data.

Operating over 20 m range, tripod-mounted LS 420 can scan in 360Ã-

Read More »

Advantages of VPSA Technology for Your Application

VPSA technology uses different equipment than PSA and requires significantly less energy, resulting in an average cost savings of one-third to one-half in comparison to PSA systems.

Read More »World DLA Demonstrates Driver's License Verification Technology at April 3-5 Car and Truck Rental Conference

BUFFALO, New York, March 27 -- World DLA announced today that it will be demonstrating its new driver's license verification technology at the 2006 Car Rental Show - taking place at the Mirage Hotel in Las Vegas, Nevada during April 3 to 5, 2006. The annual car and truck rental conference and expo is expected to attract over 1,000 representatives of independent and franchised rental operations...

Read More »Keithley Plays Key Role in New IEEE Test Standards for Carbon Nanotubes

Cleveland, Ohio - March 7, 2006 - Keithley Instruments, Inc. (NYSE:KEI), a leader in solutions for emerging measurement needs, announces that its Model 4200 Semiconductor Characterization System conforms to and supports the just-released IEEE (Institute of Electrical and Electronic Engineers, Inc.) standard for electrical testing of carbon nanotubes. The recently approved IEEE 1650TM-2005...

Read More »Rudolph Technologies Announces Multiple-Tool Order from Premier Memory Solutions Provider in Taiwan

DRAM manufacturer intends to boost yield with automated macro defect inspection Flanders, New Jersey, March 13, 2006Ã-¯Rudolph Technologies, Inc. (Nasdaq: RTEC), a leading provider of process control equipment for thin film measurement and macrodefect inspection during integrated circuit manufacturing, announced today the completion of a multiple system sale to a premier memory solutions...

Read More »KLA-Tencor Enables Production Monitoring for High-Brightness LED Market with New Automated Wafer Inspection System

SAN JOSE, Calif., Nov. 9 / -- KLA-Tencor (NASDAQ:KLAC) today introduced the Candela CS20 -- the first automated wafer inspection system designed to address the defect management requirements of the rapidly growing high-brightness light-emitting diode (HB-LED) market. Leveraging a proprietary, multi-channel detection architecture, the CS20 can inspect transparent wafers and epi layers for...

Read More »FEI Completes Installation of First In-Line DA 300HP DualBeam(TM) in Japan

Top-Ten Japanese Supplier of Semiconductor Devices Adopts FEI's In-Fab Defect Analysis Solution for Rapid Ultra-High STEM, TEM Resolution HILLSBORO, Ore., Nov. 20 -- FEI Company (NASDAQ:FEIC) has completed the first Japanese installation of its advanced DA 300HP DualBeam(TM) system for automated in-fab defect analysis extendable to the 45nm design node. The in-line system, installed in the...

Read More »Defect Removal System targets potato processing industry.

Designed to detect and cut out defects in potato strips at rates to 16,200 lb/hr, ADRÃ-® 5 integrates inspection capabilities of G6 electro-optical platform with modular vision engine and trichromatic cameras. Components include Hi-Res Vis/IR cameras, belt conveyor, rotary cutter, and Iso-FloÃ-® vibratory conveyors, combined to facilitate process of aligning, isolating, inspecting, and...

Read More »

Increase Workplace Safety, Manage Heavy Loads with Equipment from A-Plus Warehouse

A-Plus Warehouse carries a wide selection of commercial and industrial material handling equipment at affordable prices. Check out the video to learn more.

Read More »