Hanson Technologies, Inc. Partners with Verdelli Farms, Inc. to Launch Pilot Program for Field Validation of Its HSVS-1000 UltraRapid(TM) Food Safety Solution for Fresh-Cut Produce

CARLISLE, Pa., April 25 -- Hanson Technologies, Inc., an innovator in UltraRapid(TM) biosensing solutions, today announced that it will work with Verdelli Farms, Inc., the largest regional produce processor on the East Coast, as its first partner site in its pilot program for validation testing of its Hanson Technologies Safe Vegetable Screening System (HSVS- 1000). The HSVS-1000 provides an...

Read More »Video Measurement System features 2-axis design.

Merlin 300 includes Quadra-Chek 300 video microprocessor with touch-screen technology. Contrast teach facility enables operator to determine component edge, and system features high specification camera, high numerical aperture objective lenses, and dimmable LED surface and substage illumination. It is also equipped with automated point data capture with full PC connectivity, and is suited for...

Read More »

Metal Detector complies with FDA requirements.

Suited for inspection of free-flowing pharmaceutical powders, Pharma GF can identify various types of metal contamination including ferrous, non-ferrous, and all grades of stainless steel. Self check capability continuously monitors sensitivity and sounds alarm if problem occurs, while high speed diverter reject minimizes product loss during contaminant removal. Variety of aperture sizes are...

Read More »

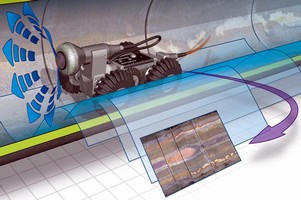

Video Inspection Crawler performs full-speed scanning.

ROVVER crawlers are available with DigiSewer(TM) digital visual sidewall scanning (DVSS) camera, which enables full-speed, Hi-Res pipeline inspection. By grabbing one frame of video at established intervals, DigiSewer generates complete sidewall scan whose length corresponds to length of pipe and height corresponds to pipe's full circumference. Scans load directly into freeware viewer on any PC...

Read More »

Retem System: Breakthrough Technology in Soil Stabilization & Erosion Control

This white paper provides an overview of Retem Systems breakthrough technology.

Read More »Vision Sensor features IP68-rated camera.

Including remote camera with separate DIN-mountable controller, PresencePLUSÃ-® Pro vision sensor features 20-pin removable terminal block, PresencePLUS software with 3-step point-and-click setup, and 14 configurable discrete I/O. Unit also offers direct connectivity to EtherNet/IP and ModbusTCP industrial networks, ActiveX utilities for exporting inspections, images, and results, and...

Read More »Agilent Technologies Launches World's Fastest 3D In-Line Automated X-Ray Inspection Solution with Uncompromised Defect Coverage

SANTA CLARA, Calif., April 23, 2007 -- Agilent Technologies Inc. (NYSE: A) today announced a breakthrough for in-line 3D X-ray inspection systems that detect printed circuit board assembly (PCBA) solder and manufacturing assembly defects. The Agilent Medalist x6000 AXI reduces customers' manufacturing conversion costs without compromising defect-detection capability. It accomplishes this by more...

Read More »

Video Inspection Crawler features rear-view camera.

Able to travel up to 1,640 ft through pipelines 6 in. and larger, SuperVision 140 evaluates conditions and identifies maintenance needs. Unit features 6-wheel drive, remote-operated camera lift that adjusts view height from 3-10 in., and monochrome rear-viewing camera with infrared illumination. Forward viewing camera pans infinitely, tilts Ã-

Read More »FEI Expands Helios Nanolab(TM) Family for Semi Market

NanoLab 400/400S to be Introduced at SEMICON Japan Giving Users a Complete Range of Advanced Solutions for Semiconductor Labs NOVEMBER 30, 2006/Hillsboro, Ore.-FEI Company (Nasdaq: FEIC) will expand its top-of-the-line Helios NanoLab(TM) family of DualBeams(TM) when it introduces the Helios NanoLab 400 and 400S systems next week at SEMICON Japan. Combining advanced focused ion beam (FIB) and...

Read More »

FireSight from Lenox Instrument Co. Provides Continuous Monitoring of Flame Impingement in Process Heaters

Trevose, PA, December 2006 - Lenox Instrument Company's FireSightÃ-® High-Temperature Remote Viewing System continuously and safely permits viewing of the flame quality and impingement if present on the tube walls of petrochemical process heaters. The FireSight System allows an operator to view the flame in real time in order to tune the furnace to eliminate this hazardous and potentially...

Read More »

Materials Processing Unit suits micromachining applications.

Developed for repairing flat panel displays, micro circuits, and wafers, Model IX-70 ChromAblate(TM) on-target inspection and short deletion system can be configured with IR, visible, or UV wavelengths to process materials from metals to polymers. Adjustable attenuator allows precise control of laser power. IX-70 incorporates co-axial CCD camera with adjustable zoom lens for alignment and...

Read More »

Aerzen USA Process Gas Blower and Compressor Installations Worldwide

Aerzen is firmly established as a global leader in compressed air, gas, and vacuum solutions. Our reputation as an industry leader is built on consistently delivering innovative products that are at the cutting edge of technology. To learn about the industries finest blowers and oil-free and oil-injected screw compressors, see our video.

Read More »