Batch Mixer blends, discharges, and sanitizes.

Sanitary 50 cu-ft rotary batch mixer, Model 700-TH-50-SS gently blends batches of ingredients in parts as small as 1 per million with 100% uniformity in less than 3 minutes, and evacuates 100% of batch. Intended for 3-A and USDA applications as well as contamination-sensitive materials, unit features internal mixing flights; 304 or 316 stainless contact surfaces with continuous, polished welds;...

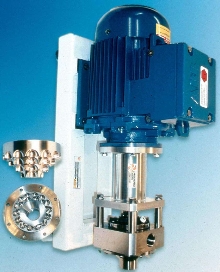

Read More »Emulsifier replaces piston homogenizer.

Ytron(TM) Model Z provides method for homogenizing, emulsifying, and imparting controlled amount of shear to processes. It has no moving parts that could impart taste to product. Incorporating up to 3 sets of toothed rotor/stators, engineered to fine radial tolerances, emulsifier processes product at high differential velocities, as many as 18 times in single pass. Four 3-A approved sanitary...

Read More »

Batch and In-Line Mixers are suited for high-shear mixing.

Utilizing FDM rotor/stator technology designs, MaelstromÃ-® line uses hydraulic shearing actions by creating impinging vortices capable of delivering typical particle sizes in 2-4 micron range with narrow size distribution. Mechanical design facilitates on-site serviceability.

Read More »

Vortex Mixers offer wide range of accessories.

ThomasÃ-® Mini Vortex Mixers are suited for test tubes, flasks, beakers, and small containers. One-touch ThomasÃ-® Touch Mixer features fixed speed of 3,200 rpm. ThomasÃ-® Analog Vortex Mixers offer variable speed control from 100-3,200 rpm for gentle or high-speed mixing in continuous or touch mode operation. With variable speed control from 1,200-2,400 cycles/min, ThomasÃ-®...

Read More »Choosing the Right Load Ring for Your Needs

A Temper® Load Ring, also known as a Constant Force Adjustable Spacer, is a precision ring designed to perform as a predictable constant force element. It is fabricated from ductile, high strength stainless alloys.

Read More »

Sanitary Mixer suits batch and continuous processes.

Series LZ Hi-Shear In-Line Mixer features mixing head with 1-12 shear-action zones consisting of high-speed rotors and stators that can produce shear rates of 200,000/sec each. Mixer processes up to 1,200 gpm with repeatability to Ã-

Read More »

Mixers suit demanding side-entering applications.

Prochem PB and MD employ Ultra VX drive belts and sheaves that provide power transmission with shock-absorbing capability. Pillow block design on PB Series reduces downtime associated with bearing maintenance, while modular design on MD Series incorporates shaft bearing cartridge. Both models, equipped with Maxflo WSE impeller, are available with up to 400 hp and output speeds to 480 rpm.

Read More »

Ultrasonic Processor treats liquids in large scale.

Model UIP16000 provides continuous power of 16,000 W with over 80% efficiency. Generator, transducer, and flow cell are housed in 2 connected stainless steel cabinets. If required, generator cabinet can be located up to 10 m from transducer with flow cell. Independent cooling system eliminates contact between aggressive air or dust and electric components. Operation can be controlled and...

Read More »

Mixer suits sanitary and research environments.

Triclover(TM) mount BRX mixer is available for low shear, high flow applications, with batch sizes between 20-250 L. Modular design accommodates 1/8-1 hp motors. Mechanical or lip seals are available, and variable speed drive is optional. All-stainless motor is offered for users requiring paint-free equipment. Applications include solids suspension, blending, chemical reactions, and promoting...

Read More »

Mixer/Agitator employs triple concentric shaft design.

Tri-Mix Turbo-Shear handles mixing problems from dispersion of powders and oils to mixing of viscous materials of more than 2.5 million cps. Center-mounted, high-shear agitator produces speeds as high as 3,600 rpm, while counter-rotating, scraped-surface agitator yields speeds of 10-50 rpm. Shaft design is suited for making toothpastes, mascaras, and gels in batch sizes of 10-1,000 gal.

Read More »

Vibratory Mixer uses no rotating parts.

Self-contained Vibratory Mixer can mix, blend, or coat granular bulk materials with powders and liquids. Continuous batch mixing system includes built-in bulk material metering hopper, liquid and powder metering systems, and electronic controls for addition of precisely metered mix components and cycle functions, eliminating need for transfer pumps, level sensors, and weigh scales. Short cycle...

Read More »

The Carbontec System: A Smarter Way to Heat Your Buildings

Carbontec's paper-thin radiant heating systems reduce energy consumption costs by warming the building surfaces instead of controlling air temperature. Check out our video to learn more.

Read More »