Radius Internal Cylindrical Grinders handle large workpieces.

WithÃ- workhead on simultaneously swiveling B-axis, STUDER S121, S131, and S141 offer thermal stability, mechanical rigidity, and interpolation from -60Ã-

Read More »

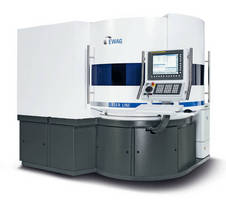

UNITED GRINDING's Vast, Advanced Technology to Stand Out at GrindTec 2014

Company to display several new innovations from WALTER, EWAG and STUDER in Hall 7-7050Ã- MIAMISBURG, Ohio – UNITED GRINDING, the largest single-source provider of complete and integrated grinding solutions, will showcase its latest grinding, eroding, laser and measuring innovations for general purpose and advanced tool and cutter production in Hall 7-7050 at GrindTec, taking place March 19...

Read More »CeramTec North America's Grinding Capabilities

CeramTec North America Corporation's grinding capabilities expands beyond the basics. CeramTec's specialized grinding equipment enables the organization to grind thin ceramic substrates to exceptional flatness, parallelism, and finish specifications. The use of advanced equipment allows CeramTec to produce superior surface finishing under the tightest tolerances. While CeramTec's grinding...

Read More »

Free Reconditioning with WIDIA(TM) Solid-Carbide Drills

(LATROBE, PA) - For a limited time, customers that purchase a new WIDIA(TM) solid-carbide drill are eligible for a free drill reconditioning. The free reconditioning is good for eligible drills purchased through June 30, 2010. (Customers have until September 30, 2010 to redeem the cards). WIDIA's a world leader in milling inserts and end mills - now's a great time to try our drills and holemaking...

Read More »

Adhesive Tapes for Biopharma Applications

Download our free eBook to learn the various applications NADCO tapes used within the healthcare sector, the many benefits they provide, and how to select the right type.

Read More »

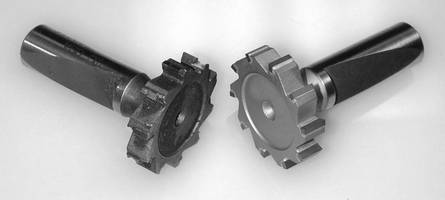

Polygon Shapes - Multi-Faceted Problem Solvers

Polygon Shapes - Multi-Faceted Problem Solvers Kinematically ground polygonal shapes have been used as drive connections for more than 25 years. What is now referred to as Polygon Systems was developed by Fortunawerke, Stuttgart, West Germany, who patented a grinding machine capable of producing matched polygonal shaft and bore diameters. The unique feature of the machine which made this possible...

Read More »

Whitney Tool Offers Re-Tipping/Re-Grinding Services

To help manufacturers and fabricators hold down production costs, Whitney Tool Company, a leading cutting tool manufacturer headquartered in Bedford, IN, now offers a comprehensive tool re-tipping service for most brands of carbide tipped cutting tools, as well as a re-grinding service to restore cutting edges to high-speed steel (HSS) and carbide tipped tools manufactured by Whitney. Through...

Read More »

New Norton-® Charger Plus Depressed Center Wheels for Stainless Steel Applications Improve Performance by 30 Percent

10/25/06 The zirconia alumina abrasive in Norton Charger Plus wheels is the best grain to cut and grind stainless steels, according to recent tests conducted by Saint-Gobain Abrasives. The smooth grinding action enhances both the cut rate and life of the wheel and lets the wheel do the work, not the operator. The clean bond contains no sulphur, iron or chlorine - eliminating the opportunity for...

Read More »Grinder Produces .000006 in. (0.15 micron) Roundness

KEENE, New Hampshire, Sept. 15, 2006 - Accura Technics Inc. announces advancements in precision grinding applicable to aerospace, automotive, bearing and optics manufacturing. In capability tests, Accura's Model 1210G CNC grinder produced .000010 (0.25 micron) roundness in ball bearing outer races and .000006 (0.15 micron) roundness in inner races. This multi-surface grinder was delivered to...

Read More »Steady Rest for Miniature Grinding

Arobotech Systems offers Grinding AUTO RESTÃ-® models for miniature grinding with standard clamping ranges down to 1mm diameter. These models feature the same follow down capability and one-micron repeatability as our larger rests. Special wear pad designs are available to fit almost every workpiece profile and clearance requirements.

Read More »NUM's Solutions for Grinding Have User-Friendly Graphical and Conversational Programming (W082)

Exhibiting at IMTS 2006 in Chicago, Sept. 6 to 13, Booth D-3232 Chicago, July 31, 2006 NUM offers a family of cost-effective control systems well suited to address all aspects of cylindrical and surface grinding. Configured with a state-of-the-art CNC, motors/drives, and very user-friendly software, these off the shelf solutions can be used in new machines or to retrofit existing machines. The...

Read More »

DoorKing Releases Advanced Long Range Card Reader System with Frequency Hopping Technology

The DoorKing DKS AVI system is at the cutting edge of automotive security technology and represents a leap forward in engineering innovation. When it comes to long-range passive card readers, we lead the industry and set the standard for quality and performance. To find out why the DoorKing DKS AVI system is taking the automotive security industry by storm, see our video.

Read More »