Grinder comes with Fanuc 16i control.

Model S31cnc universal cylindrical grinder has digital control and drive systems, and dual wheelhead arrangement with two external grinding wheels for simultaneous rough and finish grinding. Universal turret wheelhead swivels automatically, permitting external, internal, and face grinding of workpieces in single setup. Center height is 175 mm, between-centers grinding length is 650 mm, wheel size...

Read More »

Angle Grinder offers tool-less wheel changes.

WE14-150 Plus with Vario-Constamatic full-wave electronic speed control, maintains constant speed while operating during maximum load and no-load conditions. It is rated at 1,400 watts, and operates at 6,000 to 9,000 rpm with 12.0 A motor. Maximum wheel diameter is 6 in. Grinder includes 2-position side handle, S-automatic safety clutch, winding protection grid, and thermal overload protection.

Read More »

EDM Grinder facilitates honeycomb part machining.

Model 1500 Spark Erosion Grinding (SEG) system uses EDM technology to arc-grind metal parts to size and shape, precisely removing metal stock. It has precision 1.5 hp, 3600 rpm spindle, cart-mounted EDM power-pack, drive and electrical arc power cables, and six electrode wheels. Electrical current fed through spindle arbor forms controlled arc between electrode wheel and part. As spindle is fed...

Read More »

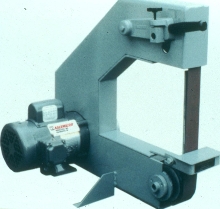

Belt Grinder has open area design for easy access.

Model BG272 benchtop belt grinder is equipped with 5 in. lower contact wheel, 1 HP TEFC direct drive motor, and 7200 rpm belt speed. Throat is 10 in. high x 13 in. deep. Unit measures 24 in. long x 12 in. wide x 24 in. high, and weighs just 80 lbs.

Read More »

How to Select a Thermal Fluid Heater for Your Process

Do you know the important factors you should consider when comparing different types of thermal fluid heaters?

Read More »

Surface Grinders have cast iron tables, saddles, and bases.

Equiptop Surface grinders employ heavy-duty walls and reinforced ribs. Machines are available with 8, 12, and 14 in. wheel dia. Equiptop handfeed models (CSG-618/818) feature timing belt table drive with handwheel indexing to 9 positions without backlash. Hydraulic models utilize hydraulic drive system with some motor driven cross movement. Fully automatic models have programmable hydraulic table...

Read More »

Die Grinder incorporates spindle lock.

Model GE700 variable speed, 2 in. die grinder requires only one wrench on its hardened and ground 1/4 in. collet. Extended spindle ideal allows for operation in confined areas, and auto-stop carbon brushes prevent motor damage. Grinder has no-load speed of 7,000 to 27,000 rpm, and is rated at 6.2 amps, 710 watts. Power switch is located on top of tool.

Read More »Grinding Machine has grinding head in six o'clock position.

TEG-3 Tungsten Electrode Grinding Machine prevents dust from being thrown upwards so that users can see clearly how grinding is progressing. It is designed for grinding tips on tungsten electrodes as used in Tungsten Inert Gas and Plasma welding. Tool will axially grind all diameters of tungsten welding electrode from 1.0 to 6.4 mm and lengths down to 15 mm with collet accessory. Its electric...

Read More »

Thread Grinding Machine handles small dimensions.

Compact Tapomat 1000 produces right or left hand threads from 0.8 - 4 mm, chucking lengths up to 100 mm, and grinding lengths up to 50 mm. Its hydraulic power pack, coolant pumps and electrical cabinet are inside enclosure and flush with machine's profile. Control system swivels in or out for operator convenience. Grinder has 6.5 hp wheelhead spindle motor. Operator can manually angle wheelhead...

Read More »

Micro Grinder is available with various size motors.

Electer E-Max Ultra-Precision, Multi-Purpose Micro Grinder uses built-in microchip processor for optimum motor output. For easy handling and control, on/off switch is located directly on motor. Available speed ramges include 1,000 to 35,000 rpm, 1,000 to 29,000 rpm and, 1,000 to 15,000 rpm. Control unit includes digital speed display in x1000 rpm, soft touch buttons, and computer control.

Read More »

Sanders and Grinders are comfortable and powerful.

Lightweight Models 6080-20 and 6081-20 7 and 9 in. sanders, respectively, Model 6088-20 7 in. grinder, and Models 6086-20 and 6089-20 9 in. grinders all have 4 hp, 15 A motors. For operator comfort and safety, they have angled rear handles and side handles, 2-finger trigger switches, 3-position side handles and spindle locks. Applications include metal fabricators, welders, steel erectors,...

Read More »

Come Alive Organics' Premium Organic Agave Provides a Healthier Choice

Come Alive Organics distributes all-natural, proprietary flavored agave for the food and beverage industry while helping children across the globe. Learn more about our agave products and our one sweet cause in this video and two-page PDF.

Read More »