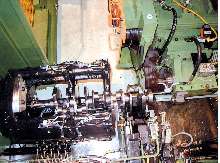

Thrust Wall/Pilot Bore Grinder suits crankshaft manufacturing.

Production grinder incorporates kiss grinding of crankshaft thrust wall and internal grinding of pilot bore. Separate external and internal grinding spindles are fitted with cubic boring nitride wheels. Machine centers and supports crankshaft on main journal centerline to hold thrust wall perpendicularity and pilot bore concentricity to main bearings within 0.010 and 0.020 mm, respectively....

Read More »

Cylindrical Grinder performs internal and external grinding.

Model S33 utilizes digital, direct-drive, 3-phase servo motors with 40 mm dia ballscrews to power X- and Z-axes. Grinding spindle is powered by 7.5 kW motor. Universal turret wheelhead swivels manually or automatically, permitting external, internal, and face grinding of workpieces in single setup. Peripheral speed is up to 45 m/sec with infinitely adjustable speed control to 3200 rpm. Precision...

Read More »

Tungsten Grinder operates with no vibration.

Piranha II allows operators to grind tungsten longitudinally on diamond wheels and improve arc starting, arc stability, and electrode life. Enclosed grinding area protects operator from hazardous dust, sparks, abrasions, and other injury while allowing dust collection and disposal. Portable unit weighs less than 10 lb and grinds .040 through 3/32 in. tungsten at any angle from 15-45Ã-

Read More »

Turning/Grinding Center reduces processing time.

Stratos Series CNC multi-tasking centers combine turning, internal/external grinding, and integrated material handling in single machine. Max swing is 380 mm, X-axis travel is 1050-1750 mm, and Z-axis travel is 250 mm. Linear drive motor delivers acceleration of 5 m/secÃ-² and rapid traverse rate of 60 m/min. Internal grinding system features 36,000 rpm, 8.5 kW spindle drive, and external...

Read More »

Custom Progressive Metal Stamping for Manufacturing EMI Shielding

A Guide to Containing EM Radiation Through Custom Progressive Metal Stamping

Read More »

Profile Grinding System suits lean, cellular production.

Blohm Profimat MC traveling-column machine is capable of multi-axis grinding in 2,000 mm-wide footprint. Access from front and back allows units to be set side by side. Modular platform concept includes GE Fanuc 18i CNC control, machine bed, column, wheelhead, and machine table. Linear guideways in all axes consist of 6-row ball and 4-row roller bearing systems that provide stick-slip free...

Read More »

Cylindrical Grinder tackles short runs and mixed lots.

Model S151cnc features modular design and digital control and drive systems. Swing diameter is 350 mm, between-centers grinding length is 200 mm, and chuck capacity is 150 kg. Turret head arrangement presents 2 grinding spindles for rough and finish grinding in same set-up. Spindle configuration is ID/ID or combination ID/OD for universal applications. Grinder features max spindle diameter of 170...

Read More »

Rotor Beater Mill produces powders in large quantity.

Model SR 300 processes materials with feed sizes up to 15 mm to fineness below 80 micron. Batch output is up to 30 L or 360 kg/hr in continuous mode. Mill achieves circumferential speed of 18,000 rpm. Circular screens, with hole diameters from 0.08-10 mm, determine final fineness of sample. Metal conidur filter provides for convenient handling. All parts in contact with sample are made of...

Read More »

Grinder provides creep feed and flat surface grinding.

Planomat Universal Surface/Profile Grinder is assembled from base modules, including machine bed, column, wheelhead and machine table. Linear guideways in all axes consist of 6-row ball and 4-row roller bearing systems. Grinding range is 800 x 400-2,000 x 600 mm, and grinding wheel is 400 x 80 x 127 mm. Variable speed, 18 kW main spindle achieves speeds to 6,000 rpm. GE Fanuc 18i CNC control...

Read More »

CNC Machine provides centerless grinding of small parts.

Kronos S permits straight plunge grinding and 15Ã-

Read More »

CNC Grinding Machine performs multiple part grinding.

With up to 8 available axes, Model 300 offers various chucking devices to clamp short and long components. Turret can be equipped with 4 spindles, permitting internal and external grinding operations. Precise indexing is accomplished via HIRTH gear curvic coupling. Machine utilizes spheroidal, one-piece, cast iron bed for rigidity and stability as well as Siemens 840D control with Windows(TM) NT...

Read More »

Error Proofing by Design

Sturtevant Richmont's torque tools help customers cut rework and warranty costs while increasing throughput.

Read More »