Surface Grinder delivers ergonomic operation.

Hum-B allows users to stand upright during operation. Equipped with 6,000 rpm Dewalt grinder, 12-segment diamond wheel, and 5 in. caster wheels, unit features gas-filled shocks for level grinding. Product, suited for use on concrete, stone, or masonry, is also equipped with 150 W halogen light, 2 in. vacuum port, and Dust Grabber shroud, providing 99% dust-free performance with no suction lock.

Read More »

Walk-Behind Concrete Grinder offers ergonomic operation.

Equipped with diamond grinding wheel, EBS 125 walk-behind, 5 in. concrete grinder removes epoxy, paint, and other coatings. It performs concrete finishing and surface preparation with 14 A motor. Walk-behind cart eliminates need to bend over and work on hands and knees. Power outlet on cart accommodates grinder plug, letting user activate grinder via on/off switch on cart handle. Grinder can also...

Read More »

Calender Roll Grinder grinds in-place.

Portable Roll Grinder mounts directly onto framework of calender equipment to let users grind rolls in their own bearings without hand or block grinding. Eliminating need to remove rolls, self-reversing, traversing grinder can redress calender rolls in-place up to 240 in. long. Grinder can achieve tolerances to 0.0005 in. on diameter, concentricity, and straightness, with finishes as fine as 12...

Read More »

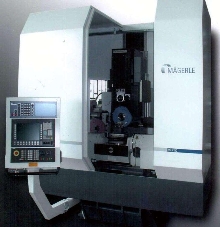

Multi-Axis Grinding Center offers flexible operation.

Equipped with automatic tool changer, MFP 50 features wear-free, hydrostatic wrap-around guideways in Y-axis and Siemens Sinumerik 840D digital controls. Unit employs symmetrical traversing sliding column design for static, dynamic, and thermal stability. Capable of up to 7-axis grinding of parts in horizontal, vertical, or inclined orientations, center features rapid traverse rate of 790 ipm on...

Read More »

Hydrogen and Check Valves

Hydrogen powers various sectors, offering cleaner energy solutions. This white paper describes the different types of hydrogen as well as the crucial role of reliable check valves in its production, storage, and distribution.

Read More »CNC Grinder accommodates shaft lengths up to 1,200 mm.

Optimized for use with CBN abrasives, Landis LT1-1200 CNC shaft grinder features cast iron bed; linear motor driven, hydrostatic wheel feed system; motorized, hydrostatic spindle; and linear-guided foot stock with rotary dresser. It uses PC-based open architecture control and accommodates 80-350 mm dia wheels. Manual or automatic loading machine operates at speeds up to 200 m/sec, grinding...

Read More »

Large Angle Grinders/Sanders produce minimal vibration.

Series 1800 incorporates vibration absorbing rings in 3-position, side-assist handle and between main trigger handle and motor housing. Seven inch Models 1873-8 and 1873-6 feature 3 hp motor and operate at 8,500 rpm and 6,000 rpm, respectively. Models 1893-6 and 1894-6 are 9-in. grinders operating at 6,000 rpm with 3 hp and 4.5 hp motors, respectively. Models 1853-5 and 1853-6 are 7 and 9 in....

Read More »Tungsten Grinder includes built-in dust collection system.

Hand-held Sharpie(TM) DXV Vacuum Grinder allows dust-free electrode preparation to facilitate maintenance of clean weld environment, while delivering consistent grind angle and diamond-ground finish.

Read More »

Belt Grinders feature 3 contact wheel impact points.

RadiusMaster Grinders offer 5 different work station/contact wheels including rotating small wheel cassette with Ã-¾, 1, and 1Ã-½ in. wheels; 3Ã-½ in. wheel; 8 in. wheel; pipe notching station; and strap for contours. TeflonÃ-® is used between moving components with vital pivot parts tapered and adjustable to provide wear-proof operation. No tools are needed to change wheels, tilt...

Read More »

Punch Grinding Machine uses 30 hp spindle for precision.

Capable of grinding round, eccentric, and step punches up to 6 in., PGX produces optimal grinding results for HSS and carbide punches. Unit is equipped with 30 in. grinding wheel, directly programmable via CNC from 200-3,000 rpm. PunchCam software allows for programming of generic and complex shapes. System also employs digital servo drives, cast iron work head, and automatic wheel balancer. All...

Read More »

Profile Grinder is suited for precision applications.

Equipped with Siemens 840 D CNC control, Jung J 630 surface and profile grinder incorporates double V guide construction and PA 37 CNC system that allows continuous profile dressing of grinding wheel. Spindle, hydraulic system, and diving column enable micron precision during grinding process. With max load of 130 kg, grinder has 600 x 305 mm grindable workpiece surface and cuts at speeds to 35...

Read More »

Micro Air's Dust, Fume, Mist Collection Equipment Facilitate a Safe Work Environment

Dust, fume, and mist collectors from Micro Air promote a safer, more productive work environment. Our wide array of products are available to the industrial manufacturing sector for processes such as welding, cutting, grinding, blasting, and more. Check out our video to learn more.

Read More »