Metal Treaters Inc. Expands Production Capabilities with Ipsen's ATLAS Atmosphere Furnace

CHERRY VALLEY, IL - Ipsen recently shipped an ATLAS batch atmosphere furnace and ancillary equipment – temper, washer, loader, endo generator and load table – to Metal Treaters Inc. This complete atmosphere system will augment their existing atmosphere equipment and offer a higher level of flexibility with the ability to provide several processes: carburizing, neutral hardening and...

Read More »Lindberg/MPH Ships Pit Furnace to a Leading Manufacturer of Mechanical Components

Riverside, MI – Lindberg/MPH announced the shipment of a pit furnace to a leading manufacturer of mechanical components. This industrial pit furnace performs a steam treating process on tool steels. Steam treating produces an oxide film on the surface of the part which improves wear resistance, improves corrosion resistance, and provides a uniform blue-black finish. The heat treating furnace...

Read More »Lindberg/MPH Ships Two Melting and Holding Furnaces to a Leader in the Automotive Industry

Riverside, MI – Lindberg/MPH announced the shipment of two gas fired, cast iron pot furnaces to a leader in the automotive design and manufacturing industry. The two pot furnaces will be used for melting and holding Kirksite, an alloy of Aluminum and Zinc. Cast iron pots were also supplied as accessories to the pot furnaces. These rugged cast iron pots are designed for years of operation. One...

Read More »

L&L Special Furnace Co., Inc. Has Delivered A Floor Standing Dual Chamber Box Furnace to an Aircraft Maintenance Repair and Overhaul Station in Oklahoma.

QDA Series: High Uniformity, Dual Chamber Furnace Used Primarily In the Aerospace Field L and L Special Furnace Co., Inc. has delivered a floor standing dual chamber box furnace to an aircraft maintenance repair and overhaul station in Oklahoma. The furnace is an LL model QDA836 with the top chamber used for heat treatments of various steels and alloys up to 2,200Ã-

Read More »

Taking a New Product to Market: Outsourcing vs. Internal Product Development

To learn if outsourced new product development (NPD) is right for your needs, and how companies like Vollrath Manufacturing Services can help, download this white paper now.

Read More »CAN-ENG FURNACES INTERNATIONAL LIMITED has Been Contracted to Supply a Wide Plate Quench and Temper Line for the Steel Authority of India Limited (SAIL)

Niagara Falls, Ontario, Canada – CAN-ENG FURNACES INTERNATIONAL LIMITED has been contracted to supply a wide plate Quench and Temper line for the Steel Authority of India Limited (SAIL). The equipment will be installed at the Special Plate Plant facility of the Rourkela Steel Plant (RSP), Orissa India.Ã- The roller hearth furnace technology will incorporate a custom designed restrained...

Read More »Ipsen Orders Reflect Aerospace Industry Trends

CHERRY VALLEY, IL – According to Nasdaq, several new emerging markets, as well as developed nations, are boosting defense spending and generating business for U.S. Aerospace and Defense companies, even as the U.S. Aerospace and Defense sector battles budget cuts and spending constraints. An improving global economy, increased defense spending in other countries, and technological innovations...

Read More »

Lucifer Furnaces Supplies Box Furnace to Lycian Stage Lighting

Lycian Stage Lighting, a leading American based manufacturer of theatrical followspot lights has updated its heat treating with a Lucifer Furnaces bench style box furnace.Ã- Lycian Stage Lighting’s products can be found in venuesÃ- from High School auditoriums, on Broadway, and in the Olympic Opening and Closing Ceremonies. Ã- Model HA7-A9 has chamber dimensions of 6”x6”x9”...

Read More »

Thermal Technology Ships 14 K1 Sapphire Crystal Growers to Europe

SANTA ROSA, Calif.-Ã- Thermal Technology, a leading manufacturer of crystal growth equipment and high temperature furnace systems, recently shipped 14 K1 HB LED-grade sapphire crystal growers to a customer in Europe.Ã- The K1’s large 90kg sapphire boule is optimized for 4” and 6” cores used in LED production, with 8” cores possible. “We continue to strengthen our position in...

Read More »

Ajax Tocco Magnethermic Shanghai Commissioned an 18MW, 60MTPH Induction Heating Furnace

Ajax Tocco Magnethermic Shanghai has installed and commissioned an 18MW, 60MTPH induction furnace for in-line pipe heating prior to stretch reduction at the Baoji Petroleum Steel Pipe Co Ltd (BSG) mill in Shaanxi Province, China. The 7-5/8 OD, 0.250 to 0.550 wall carbon steel mother tube is formed in an ERW welding mill before entering the innovative 18MW, 60MTPH Ajax furnace system which...

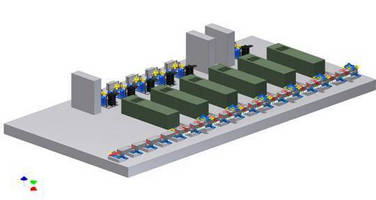

Read More »Linamar Buys New AFC-Holcroft Furnace System

Linamar, a multi-national supplier of automotive components, assemblies and castings, has purchased a new Batch Integral Quench System from AFC-Holcroft. The system is comprised of (2) UBQ ('Universal Batch Quench') integral quench furnaces, (3) UBT temper furnaces, a UBW spray washer with coalescer, a doubled-ended transfer car and (3) E-Z Series endothermic gas generator modules arranged into a...

Read More »

SRG Global Coatings Enhance Surface Durability, Efficiency, Design Flexibility

SRG Global's automotive coatings enhance the structural integrity of the finished part while also improving vehicle efficiency. Check out our video to learn more.

Read More »