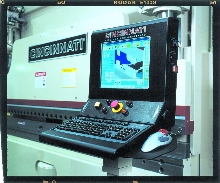

CNC Forming Center gives precision to part bends.

Autoform+ CNC Forming Center combines press brake platform with PC-based control. Bend simulation graphics provide visual instructions and guidelines, while screen displays show each step and change in part shape produced with full 360Ã-

Read More »

Riveting Machine delivers over one ton of force.

Model B-310 Pneumatic Orbital Riveting Machine provides visual status and precise adjustment of orbital forming process. Available with real-time process monitoring and process control, machine orbitally forms parts up to .312 in. diameter or equivalent area in tube, square, or other form. Tool stroke is adjustable from .06 to 1.75 in. in .001 in. increments. Standard throat depth is 6 in. and...

Read More »Tube End Former meets multi-step ram forming requirements.

Model TH:VR601-HD uses twin heads in modified C frame configurations. With optional tool changer, it will service tubes up to 3 in. diameter. Machine delivers 4-5 second cycle time per station, and has extended frame to enable backstopping to supplement clamping system. Allen Bradley Micrologix 1200-based control with limit switches provides accurate machine travel. Hydraulic system has 55 gal...

Read More »

Orbital Forming Machine assembles non-rounds.

Benchtop Model T-321 can flare oval, square, rectangular, D- and Double-D shaped pins, posts, and shafts. Non-round machined, semi-pierced, diecast, or molded tabs and bosses can be formed to secure mating parts. Form tools on machine maintain constant line contact with workpiece without intermittent peening motion. Speed and heading pressure are infinitely adjustable. Work stroke is selected for...

Read More »

Guide to FDA Approval & Compliance

Manufacturers must comply with FDA rules and regulations to ensure public health.

Read More »

Horizontal Tray Former produces 2,700 trays per hour.

Fully automatic TF 600H produces trays that facilitate handling, storage, and shipment of products on standardized pallets. Product also allows for mixed pallet loads with production of common footprint trays. Capable of producing hundreds of tray styles, unit produces 600 x 400, 400 x 300, and 500 x 400 mm footprint trays, with various depths. Trays conform to 5 and 6 down requirements, while 10...

Read More »

Tray Former features modular design.

PF 129 utilizes Model M2A glue system, Allen Bradley's Micrologix 1500 programmable logic controller, and Total Control Products 5 in. touch screen. It produces finished trays in sizes that are produce-industry standard for tray length and width, but with ability to vary depth or design. Tray former includes UL approved control panels and Lexan guarding.

Read More »

Hot Melt Case Former offers tape sealing option.

Convertible case former can switch sealing mechanisms (from hot-melt glue to pressure-sensitive tape) with drop-in cartridge that sets up in minutes. Model WF2H suits packagers and contract packagers that require corrugated case and tray forming and sealing. Convertible WF2 case former series incorporates pin & dome positive case opening technology. It handles all weights and plies of board...

Read More »Automatic Tray Erector forms stackable, secure trays.

TE-101 uses 2-stage, flap-folding method to form fold-and-lock trays without use of adhesives or staples. Machine works at speeds up to 33 trays/min and erects different tray styles, including optional corner post structure or telescoping box. No-tool changeover allows user to switch between sizes of stackable trays in less than 10 min. Built with safety interlocked Lexan windows, tray erector...

Read More »

Endforming Machine loads manually and endforms automatically.

Single-station Model LS-38S endforms tubes from 1/4 to 1 1/2 in. diameters, with swage lengths through 2.5 in. It delivers 8 tons of force to reduce, expand, flare, and bead ferrous and nonferrous tubes of almost any length. Tool changing is accomplished by removing 4 screws to remove clamp set, and one screw to remove forming tool.

Read More »End Former sizes tubing.

S:501 uses drop-in style segmented tooling to expand, reduce, and form beads at ends of tubes. It has 5 in. dia hydraulic cylinder, 4 in. stroke, air cooled heat exchanger, compact 10 sq ft footprint and works on tubes up to 3.00 in. OD. Former has Allen-Bradley Micrologix controller and proximity switches, 10 hp hydraulic system capable of 2300 psi, and Parker D03 series directional control...

Read More »

New Davenport Hybrid Machine Offers Unique Flexibility for Parts Manufacturing

The Davenport Hybrid machine offers greater flexibility, easier set-ups, and faster cycle times. Check out the video to learn more.

Read More »