Model 2175B Track Cutter is Made from High Carbon Steel with a Non-Glare Finish

Equipped with cushioned Xuro-Rubber™ hand grips and a Light Touch™ return spring. Features Micro-Shear® blade that bypass cutting action which leaves clean square cuts . Used in HO, N and Z (code 100) scale modeling applications.

Read More »

Sinto America Delivers a Y Track Spinner Hanger Blasting Machine

GRAND LEDGE, Mich., July 25, 2019 /PRNewswire/ -- Continuing their manufacturing excellence, Sinto America recently manufactured and shipped a KSB Y Track Spinner Hanger for NPK Construction Equipment. NPK is a leading manufacturer of hydraulic attachments, pedestal booms & more in construction & demolition industries. See Sinto's KSB Spinner...

Read More »

New LAS 200.1 Laser Fume Extractor Provides High Flexibility in Changing Process Conditions

HEPA filter is offered in combination with an adsorption filter for increasing the main filter’s separation rate up >99.995%. Pre-filter package along with filter mat and panel filter enables considerably longer filter life. Can be combined with various capturing elements such as extraction arms or hoses/tubes (DN 50, 75, 80).

Read More »

New Dual Point Mini Cooler Operates at Quiet 76 dBA

Provides a stream of 20 degrees F cold air to prevent heat buildup, reduce downtime and increase productivity. Eliminates burning, melting and heat related breakage. Ideal for cooling sewing needles, blades, small tools and lens grinding applications.

Read More »

Accelerating Composites Production with Dielectric Cure Monitoring

This white paper provides an in-depth explanation of how dielectric monitoring works, and why it's the best choice for any company working with advanced composite materials.

Read More »

New CRYO-powRgrip Technology is Based on Standard Toolholders

Eliminates secondary cleaning operations, for medical industry part-production operations. Helps to increase the tool life and productivity. Enables high-speed cutting in the toughest materials.

Read More »

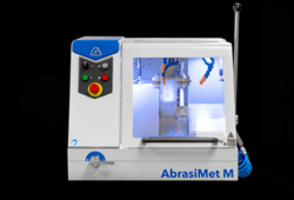

Buehler Releases AbrasiMet M bench-top Cutter for Metals and Other Tough Materials

Contains a manual saw with a powerful 5.5 hp (4kW) motor and can accommodate 10”[254mm] to 12”[305mm] optimized blades. Designed with 30-gallon recirculation tank along with nested tank and filtration screen. Offered with Bright LED light strips to increase visibility of samples.

Read More »Downdraft Table helps protect firefighters. .

Consisting of combination workbench and extraction/filtration system, Plymovent Downdraft Table provides safe and effective workspace where users can pre-clean soiled gear of contaminants. Product can help protect firefighters from exposure to dust and hazardous debris found on turnout gear and boots.

Read More »

Cascades-® EVOK-® Expands into the US with Johnsonville-® Fresh Sausage Products

KINGSEY FALLS, QCÃ- – Cascades inc. (TSX: CAS), a leader in the recycling and manufacturing of green packaging and tissue paper products, is pleased to announce the arrival of Cascades EVOKÃ-® on the American market in collaboration with Johnsonville Sausage. This is the first national sausage brand to use polystyrene foam trays which are made of 25% recycled content and now...

Read More »Coveris Presents Innovative Meat Packaging Solutions at IFFA 2016

Coveris, the world’s sixth largest plastic packaging solutions provider, will present its wide range of flexible and rigid packaging offerings for meat at this year’s IFFA. Next to solutions for assorted meat and dried foods, the Company will showcase products for meat and poultry derivatives, delicatessen products, offal, giblets and ready meals. This year’s fair stand will display both...

Read More »Ultrasonic Tool Head cuts composite and gasket materials.

Available for static table and conveyor systems, Ultrasonic tool head operates at 20,000 Hz (20,000 oscillations/sec)Ã- and is designed for cutting adhesive-backed, composite, or gasket type materials. Ultrasonic technology reduces blade gumming and friction between material and blade. While ultrasonic spindle has 3 in. stroke and is available with 30Ã-

Read More »

ISO-Certified Plastic Injection Molding from Rodon

The Rodon Group is a proven leader in high-volume, close tolerance injection molding. We offer globally competitive, innovative manufacturing solutions for a broad range of industries. Check out our video to learn more.

Read More »