Distech DS1100 Parts Feeding Machine

Increases Production, Reduces Repetitive Motion Distech Systems DS1100 eliminates hand loading of testing equipment. This reduces the health problems associated with repetitive motion. A seven-axis articulating robotic arm provides greater dexterity for unloading parts from trays to conveyors and reloading them. Previous generation DS1100 were equipped with four-axis, non-articulating robots....

Read More »Ultimate Coal Feeder Causes Traffic Jams

The Ultimate Coal Feeder by JVI was a real show stopper at the Energy Generation Conference in Bismarck ND on January 30th. This small but bustling show is always a sell out. The JVI Ultimate Coal Feeder live action demo model caused a traffic jam at the corner in front of JVI's booth- with all the people stopping to watch it feed tootsie rolls for demonstration. Actual models for feeding coal...

Read More »

Vibratory Bowl Feeder has electronic voltage controller.

Developed for feeding, orienting, and stacking of chain links, vibrator bowl feeder features two outlets that are at 180Ã-

Read More »

Feeder/Unscrambler orients containers vertically.

Designed to orient and feed containers vertically, model NEVF features integrated hopper and belt-less design suited for pharmaceutical applications. Solution, supplied with its own starwheel, will discharge onto customer's conveyor. It also integrates with filler, feeding containers into filler's starwheel. Small and/or unstable containers can be fed into pucks, and machine can be changed over...

Read More »

How Is Expanded Metal Foil Made?

Expanded metal foil is a lightweight coil of metal that has been slit and stretched to create a uniform mesh pattern of openings.

Read More »

Loading Device meters additives into gravimetric feeder.

Designed for MaguireÃ-® MGF feeder, loading device is used to meter colorant or additive into plastics processing machine. It transports material to feeder from gaylord, drum, or other container and fills feeder just once, upon signal from feeder controller that level of color or additive has fallen to 10% of feeder hopper capacity. Loss-in-weight measuring function of feeder continually...

Read More »OEM Increases Accuracy by Applying Mechatronic Design Principles Using Allen-Bradley Controls from Rockwell Automation

Schenck AccuRate develops gravimetric feeders backed by Rockwell Automation's vast industry knowledge, standards expertise and full portfolio of integrated controls MILWAUKEE, Jan. 14, 2008 - Feeder and meter manufacturer Schenck AccuRate is now incorporating Allen-Bradley products from Rockwell Automation into its line of MECHATRONÃ-® gravimetric feeders, providing end users with increased...

Read More »Manncorp Celebrates San Diego Expansion with Free Feeders for ECM-EXP Purchasers

Manncorp is celebrating its newly enlarged San Diego showroom and additional staff appointments with a blockbuster incentive on the popular ECM-EXP pick & place system. For a limited time, the machine -- with an Internet price of $37,500 -- will come with a wide assortment of taped, stick and waffle tray feeders at no additional charge. According to Henry Mann, CEO, This free bonus, with a total...

Read More »Metso to Supply Minerals Processing Equipment to Gold Reserve in Venezuela

Metso Minerals will supply minerals processing equipment to Gold Reserve Inc. for its Brisas goldcopper project in Venezuela. The delivery will be completed by the end of 2009. The value of the order is approximately EUR 47 million. The order is included in Metso's second quarter order backlog. Metso's order comprises two SAG mills, four ball mills and two VERTIMILL grinding mills. Additionally,...

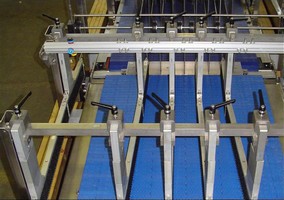

Read More »PSI Engineering and Cornerstone Automation Systems Inc. Automate the Telecommunications Industry's Kitting Process

Mississauga, ON, Tuesday July 3, 2007 PSI Engineering teamed up again, with Cornerstone Automation Systems, Inc., a leading-edge Texas, USA manufacturer and integrator, by supplying a premier telecommunications organization with an industry first automation solution to increase the efficiency and decrease the operating costs of their distribution center. With the number of DSL orders increasing...

Read More »

Solid-State Infeed enables low-pressure product conveying.

Engineered to eliminate line jams during packaging process, Zero-Gap II(TM) Infeed monitors and controls product movement to maintain constant low line pressure and optimize machine uptime. Complete product conveyor assembly, installed between upstream product conveyor and original infeed of machine, features flexible design and gentle handling capabilities. It distributes product from nested...

Read More »

Does Your Parking Lot Make a Good First Impression?

To enhance its appearance by removing oil stains, Terminator-HSD uses micro bacteria to remove the stain without harsh chemicals, acids, or detergents. Check out the video to learn more.

Read More »